Numerically-controlled lathe based on mechanical-electrical integration

A numerical control lathe and electromechanical technology, applied in the field of numerical control lathes, can solve the problems of poor adaptability of shaft-shaped workpieces or cylindrical workpieces, and achieve the effects of simple structure, good processing effect and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

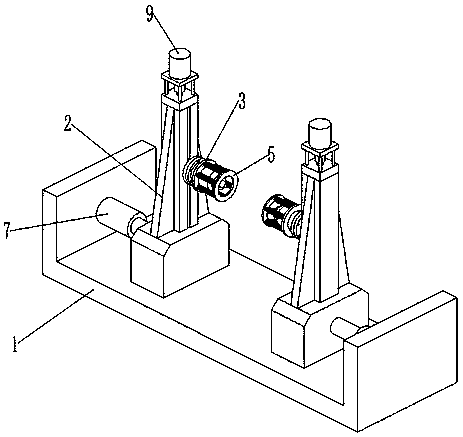

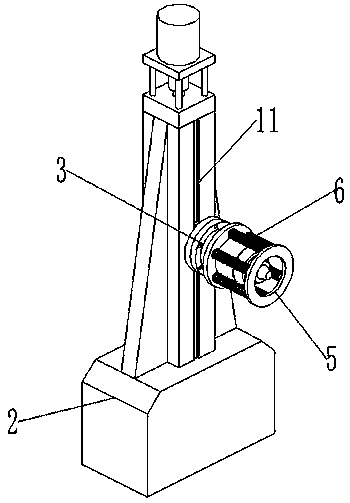

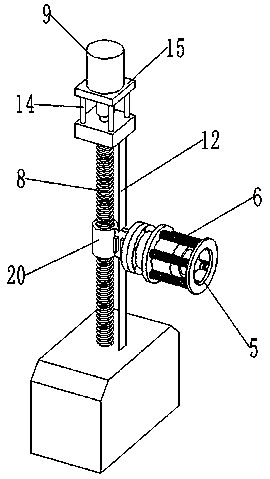

[0031] Such as Figure 8 Shown is a clamping device of a CNC lathe clutch in the prior art, including a base 1, the left and right sides of the top of the base 1 are respectively fixedly connected with a first support column 2 and a second support column 3, the first support column The left side surface of 2 is fixedly connected with a fixed frame 4, and the inside of the fixed frame 4 is fixedly connected with a fixed plate 5, and a slide bar 6 is fixedly connected between the fixed plate 5 and the inner wall of the fixed frame 4, and the left surface of the fixed plate 5 is fixedly connected There is a first sleeve 7, the end of the first sleeve 7 away from the fixed plate 5 is sleeved with a threaded rod 8, the surface of the fixed frame 4 is fixedly sleeved with a bearing 9, the inner ring of the bearing 9 is fixedly sleeved with the threaded rod 8, The end of the threaded rod 8 away from the first sleeve 7 runs through the bearing 9 and is fixedly connected with the turnt...

Embodiment 2

[0043] Embodiment 2 is a further improvement to Embodiment 1.

[0044] In practical application, considering that debris generated during workpiece processing may enter the chute 11 and adhere to the screw rod 8, affecting the transmission of the screw rod 8, an elastic belt 12 that can cover the chute 11 is also provided here. Specifically, as image 3 and Figure 4 As shown, the slide block 20 divides the chute 11 into the first chute 11 and the second chute 11, the first chute 11 and the second chute 11 are all provided with a vertical elastic band 12, the elastic band 12 One vertical end is fixedly connected with the slider 20, and the other vertical end of the elastic band 12 is fixedly connected with the slide table 2. The elastic band 12 blocks the chute 11. Since the elastic band 12 is elastic, a large elastic deformation can occur , so the elastic band 12 will not occupy much space of the chute 11 .

[0045] Further, as Figure 4 As shown, the opposite vertical gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com