A preprint pressure measurement and control method

A measurement and control method and printing pressure technology, applied in printing, printing machines, printing devices, etc., can solve the problems that are difficult to popularize and apply, and achieve the effects of quantifiable evaluation criteria, good printing quality, technology inheritance and staff training

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for measuring and controlling preprinted pressure, comprising the following steps:

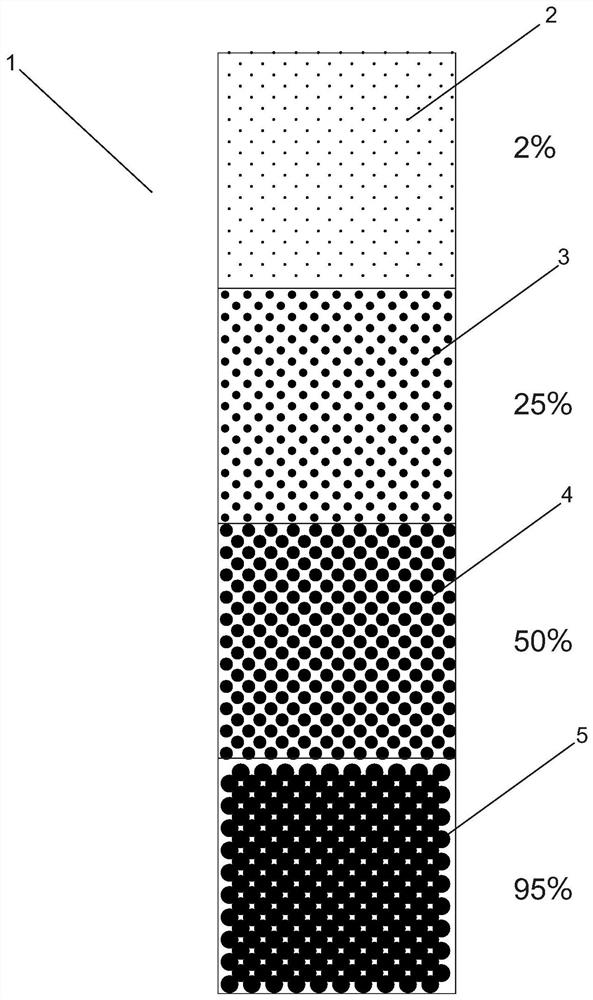

[0023] Step 1. Set the screen dot measurement and control bar 1 on each color printing plate during plate making, such as figure 1 As shown, there are 2% dots 2, 25% dots 3, 50% dots 4 and 95% dots 5 on the dot measurement and control strip 1, and the dot measurement and control strip 1 is located in the blank space outside the graphic area of the printing plate; The engraving process is completed, and the dot measurement and control bar is also generated with the printing plate through laser engraving;

[0024] Step 2. Install the printing plate for trial printing, and repeatedly adjust the printing pressure between the printing plate and the substrate color by color until 2% of dot 2 can be clearly printed on the substrate, while 95% of dot 5 is transferred to the substrate slightly blurred , the dot expansion to 97% is also acceptable, and the dot enlargement rate is meas...

Embodiment 2

[0028] In step 1, the printing plate is made through the exposure-development-fixing process. In step 2, it is also acceptable to transfer 95% dot 5 to the substrate and enlarge it to 96% dot. All the other are with embodiment 1.

Embodiment 3

[0030] In step 2, it is also acceptable to transfer 95% dot 5 to the substrate and enlarge it to 98% dot. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com