Blow molding PMMA/ASA resin with ultrahigh melt strength and preparation method thereof

A technology of ASA resin and melt strength, which is applied in the field of blow molding PMMA/ASA resin composition and its preparation, can solve the problems of blow molding parison sagging and low melt strength, and achieve stable melt strength and high melt strength. High, consistent performance and controllable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

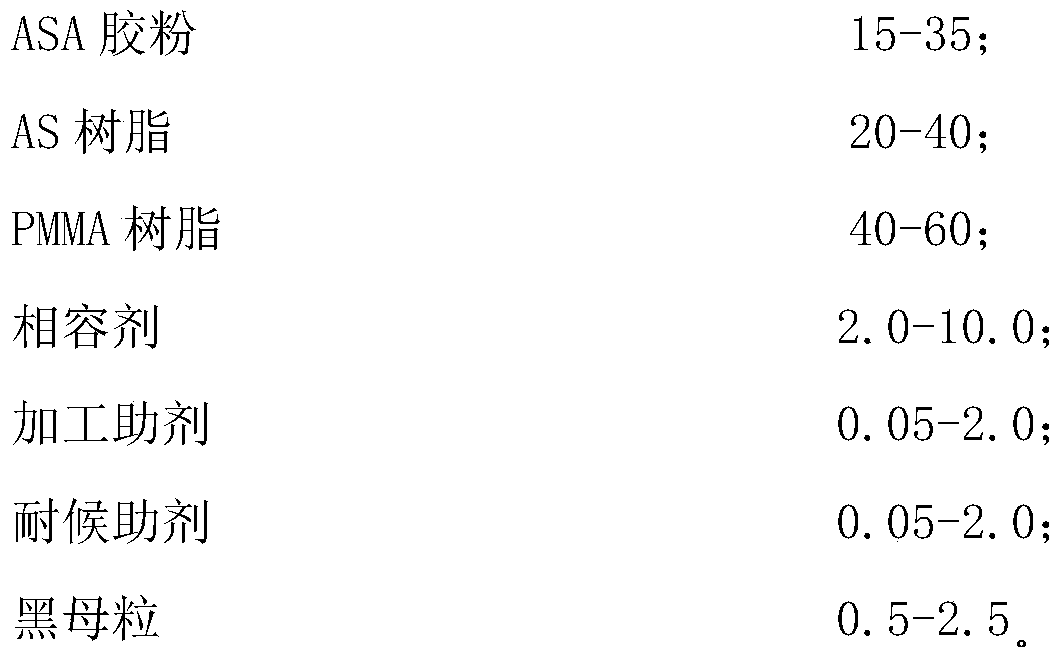

Method used

Image

Examples

Embodiment 1

[0042] An ultra-high melt strength blow molding resin PMMA / ASA composition is prepared by using the following components and raw materials in parts by weight: 15 parts of ASA resin, 20 parts of AS resin, 60 parts of PMMA resin, 4 parts of compatibilizer, 0.1 part of processing aid, 0.1 part of weather resistance additive, and 1.0 part of black masterbatch.

[0043] Among the above raw materials, the weight average molecular weight of ASA resin is 300,000g / mol, the content of acrylate rubber is 45%, and the number average particle diameter of rubber is 150nm; the weight average molecular weight of AS resin is 5000,000g / mol; the weight average molecular weight of PMMA resin 150,000g / mol; compatibilizer is St / MAH-g-MMA graft copolymer, its weight average molecular weight is 80,000g / mol; St (styrene), St (maleic anhydride), MMA (methacrylic acid The molar ratio of methyl ester) in the polymer is 20:40:20.

[0044] (1) premixing the above-mentioned raw materials in a high-speed mi...

Embodiment 2

[0047]An ultra-high melt strength blow molding resin PMMA / ASA composition is prepared from the following components and raw materials in parts by weight: 35 parts of ASA resin, 20 parts of AS resin, 40 parts of PMMA resin, 4 parts of compatibilizer, 0.1 part of processing aid, 0.1 part of weather resistance additive, and 1.0 part of black masterbatch.

[0048] Among the above raw materials, the weight average molecular weight of ASA resin is 300,000g / mol, the content of acrylate rubber is 45%, and the number average particle diameter of rubber is 150nm; the weight average molecular weight of AS resin is 5000,000g / mol; the weight average molecular weight of PMMA resin 150,000g / mol; compatibilizer is St / MAH-g-MMA graft copolymer, its weight average molecular weight is 80,000g / mol; St (styrene), St (maleic anhydride), MMA (methacrylic acid The molar ratio of methyl ester) in the polymer is 20:40:20.

[0049] (1) premixing the above-mentioned raw materials in a high-speed mixer; ...

Embodiment 3

[0052] An ultra-high melt strength blow molding resin PMMA / ASA composition is prepared by using the following components and raw materials in parts by weight: 20 parts of ASA resin, 30 parts of AS resin, 45 parts of PMMA resin, 4 parts of compatibilizer, 0.1 part of processing aid, 0.1 part of weather resistance additive, and 1.0 part of black masterbatch.

[0053] Among the above raw materials, the weight average molecular weight of ASA resin is 300,000g / mol, the content of acrylate rubber is 45%, and the number average particle diameter of rubber is 150nm; the weight average molecular weight of AS resin is 5000,000g / mol; the weight average molecular weight of PMMA resin 150,000g / mol; compatibilizer is St / MAH-g-MMA graft copolymer, its weight average molecular weight is 80,000g / mol; St (styrene), St (maleic anhydride), MMA (methacrylic acid The molar ratio of methyl ester) in the polymer is 20:40:20.

[0054] (1) premixing the above-mentioned raw materials in a high-speed mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com