Water-soluble volatile stamping fluid and preparation method thereof

A stamping fluid, water-soluble technology, applied in the petroleum industry, lubricating composition, etc., can solve the problems of short anti-rust period, high use cost, not environmental protection, etc., achieve good anti-rust and anti-corrosion performance, easy to clean and handle, less irritating effect on the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

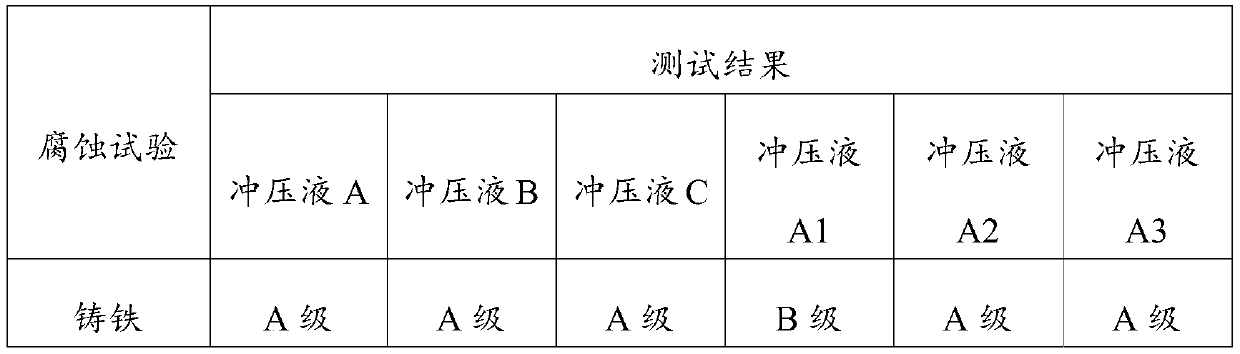

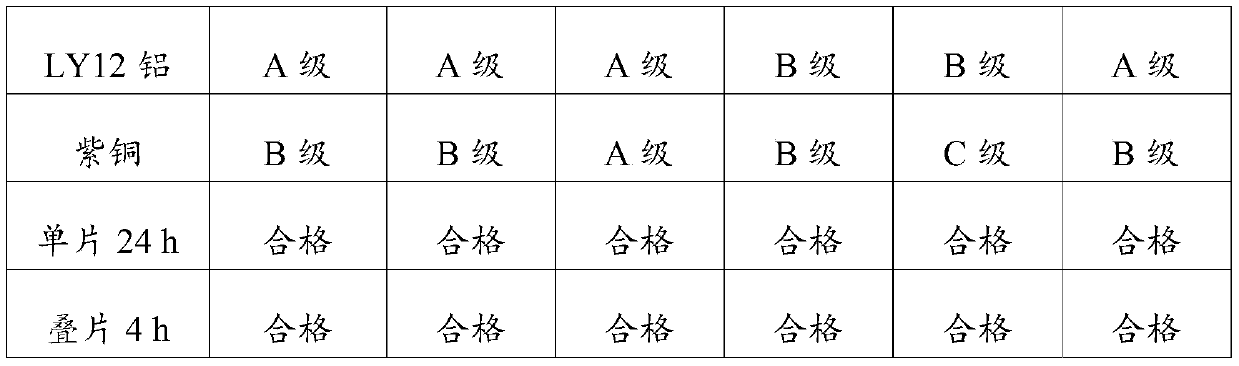

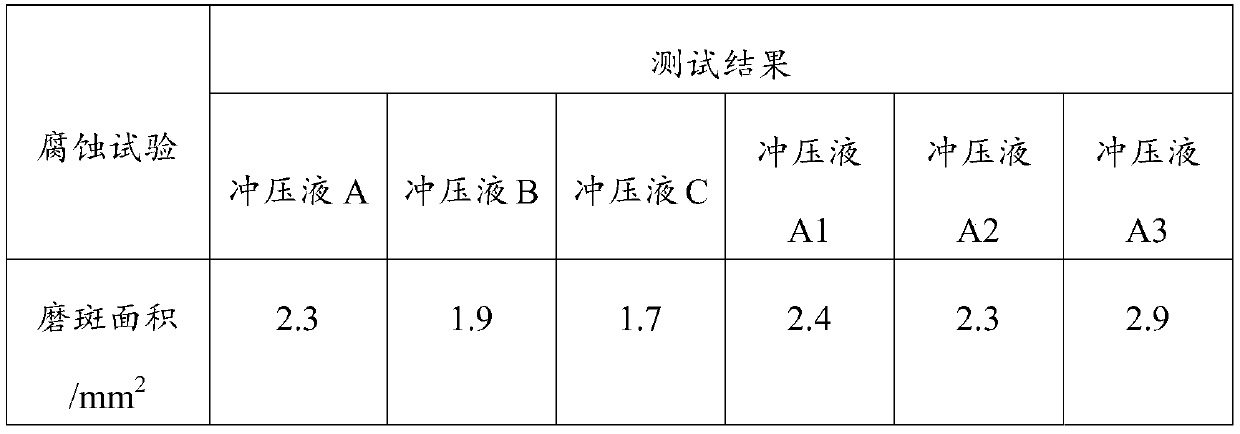

Examples

Embodiment 1

[0032] This example provides a water-soluble volatile stamping fluid, including the following preparation raw materials in parts by weight:

[0033] Composite rust inhibitor: 30-50 parts, lubricant: 5-15 parts, additives: 3-9 parts, corrosion inhibitor: 0.5-5 parts, water: 25-50 parts.

[0034] Wherein, the composite antirust agent includes a first antirust agent and a second antirust agent. The primary rust inhibitor is a mixture of specialty amines and dibasic / tribasic acids. The second rust inhibitor is at least one of triethanol, diethanolamine and boric acid. The lubricant is at least one of self-emulsifying esters and tetrapolyricinoleic acid esters. The auxiliary agent is at least one of ethanol, ether and N,N-dimethylformamide. The corrosion inhibitor is at least one of a phosphate ester corrosion inhibitor and a silicone corrosion inhibitor. The corrosion inhibitor is at least one of benzotriazole, tolyltriazole and sodium mercaptobenzothiazole.

Embodiment 2

[0036] This example provides the preparation method of the water-soluble volatile stamping fluid. The preparation method is as follows: weigh the compound anti-rust agent, lubricant, additive, corrosion inhibitor and water according to the proportion, and mix them well.

Embodiment 3

[0038] In this example, the preparation method of Example 2 and the formula of Example 1 are used to prepare a water-soluble volatile stamping fluid A, which comprises the following preparation raw materials in parts by weight:

[0039] C20 (Nanjing Gutian special amine) (the first antirust agent): 10 parts, diethanolamine (the second antirust agent): 15 parts, sebacic acid (the first antirust agent): 5 parts, boric acid ( The second antirust agent): 5 parts, tetrameric ricinoleate (lubricant): 5 parts, ethanol (auxiliary): 5 parts, ASI-80 (phosphate ester corrosion inhibitor): 0.8 parts, NEUF 815 (Silicone corrosion inhibitor): 0.5 parts, BTA (mercaptobenzothiazole sodium corrosion inhibitor): 0.2 parts, water: 53.5 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com