Metal extrusion tapping liquid

A technology of metal extrusion and extreme pressure agent, applied in lubricating composition, petroleum industry, etc., can solve the problems of high use cost, poor extreme pressure performance, general extreme pressure and lubricity, etc., achieve good cleaning, easy Cleansing or handling, less irritating effect on the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

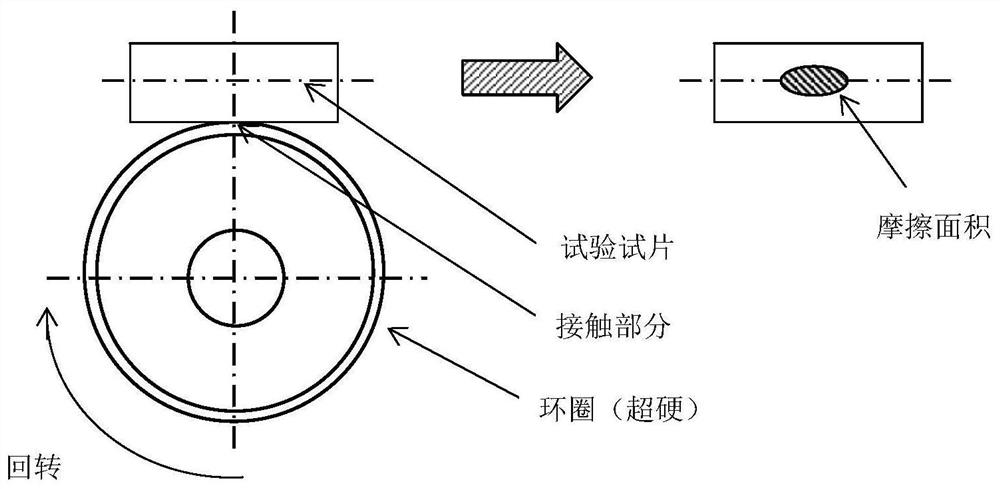

Image

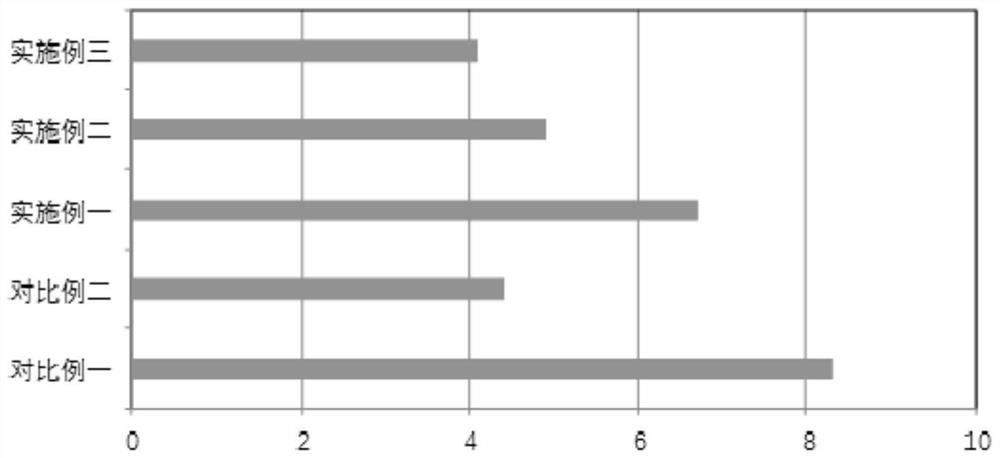

Examples

Embodiment Construction

[0026] In order to describe the technical content, achieved objectives and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments. The test methods used in the examples are conventional methods unless otherwise specified; the used materials, reagents, etc., are commercially available reagents and materials unless otherwise specified.

[0027] The PVP-coated graphene modified material used in the embodiment of the present invention is self-made, and the preparation method is as follows: dissolve PVP in water (the mass ratio of PVP to water is 5-30:100), and then dissolve graphite powder in the PVP aqueous solution (Graphite powder: water = 35-75: 25-65), and finally stir with a shear emulsification mixer for 30-120 minutes, separate solid and liquid, and collect the liquid phase for later use.

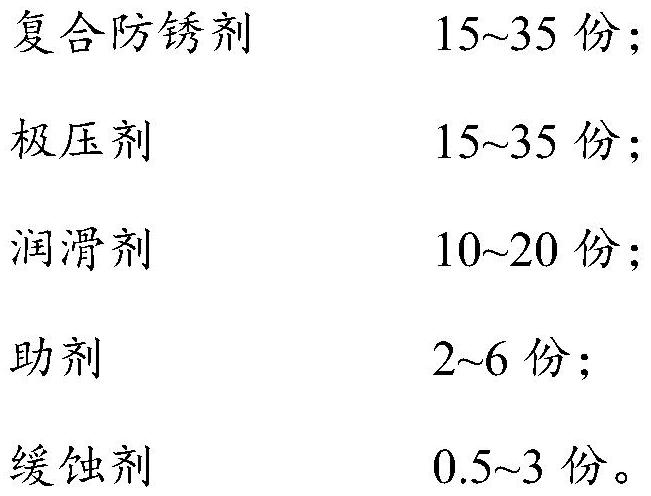

[0028] Embodiment 1 of the present invention is: a metal extrusion tapping fluid, which is composed of the following raw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com