Preparation method for coral velvet fabric

A coral fleece and fabric technology, which is applied in the field of preparation of coral fleece fabrics, can solve the problems of easy lodging and bulkiness of coral fleece fabrics, and achieve the effects of crisp appearance, good hygroscopicity and fine surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of preparation method of coral fleece fabric, its process is as follows:

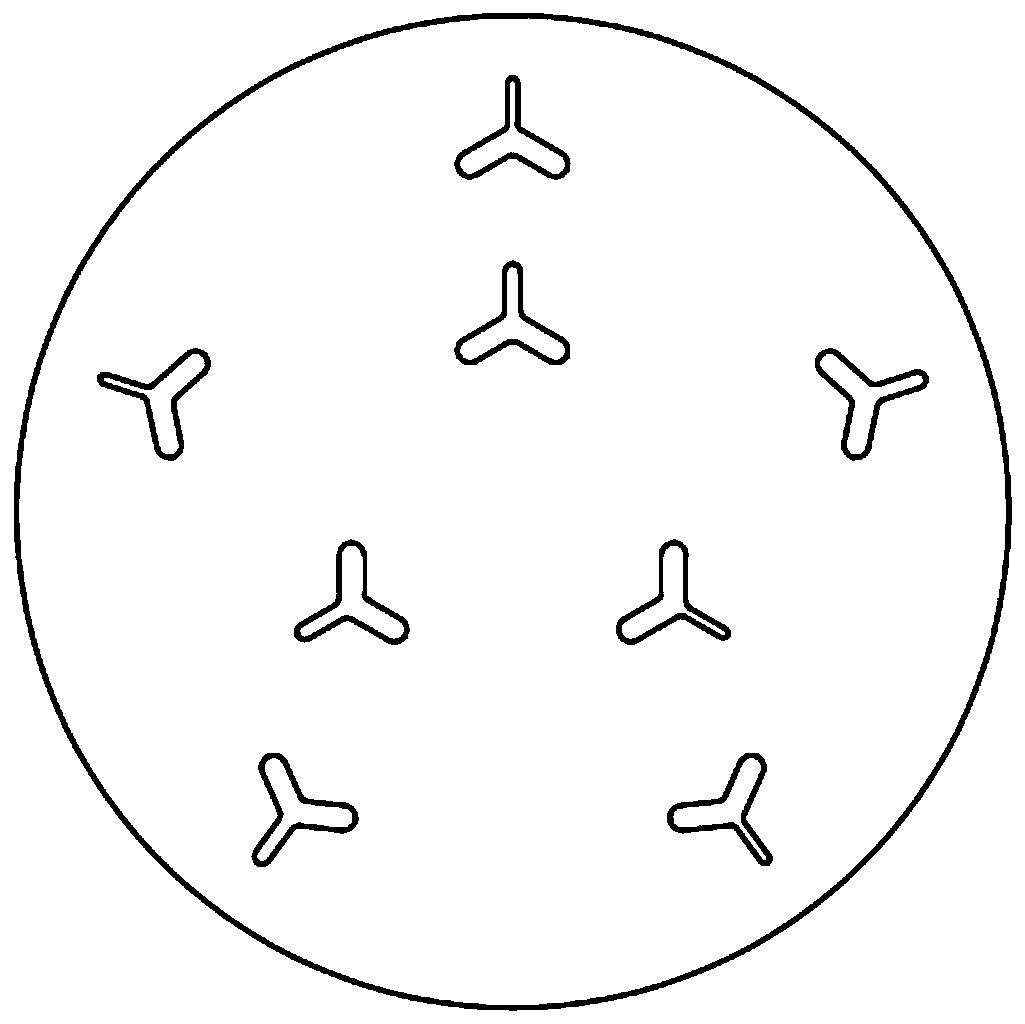

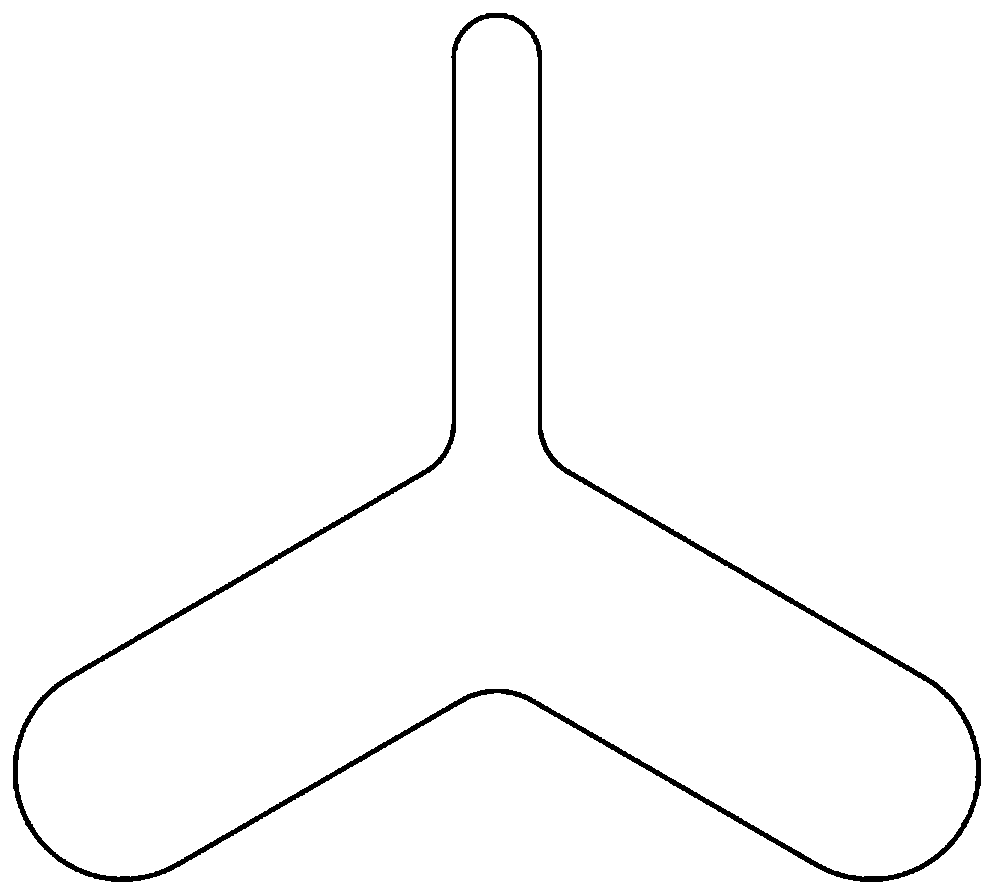

[0035] (1) Preparation of special-shaped semi-dull polyester drawn yarn:

[0036] (1.1) Extrude the PET melt (with an intrinsic viscosity of 0.61dL / g) from the trilobal spinneret hole on the spinneret and cool it with ring blowing; wherein, the number of spinneret holes is 24, and the trilobal spinneret The three lobes of the spinneret hole are of unequal width, and are equally spaced on the same circle, and along the clockwise direction, the width of the narrowest lobe is 0.1mm, 0.06mm, 0.1mm, 0.09mm, 0.06mm, 0.06mm, 0.08mm, 0.07mm, 0.12mm, 0.09mm, 0.08mm, 0.12mm, 0.09mm, 0.06mm, 0.07mm, 0.1mm, 0.07mm, 0.08mm, 0.09mm, 0.07mm, 0.1mm, 0.06mm, 0.1mm , 0.08mm, the width of the remaining two leaves is fixed, and the ratio of the maximum width of the narrowest leaf to the width of the remaining two leaves is 1.0:1.5:1.7, the length of all three leaves is the same, and the ratio of the length t...

Embodiment 2

[0045] A kind of preparation method of coral fleece fabric, its process is as follows:

[0046] (1) Preparation of special-shaped semi-dull polyester drawn yarn:

[0047] (1.1) The PET melt (intrinsic viscosity is 0.62dL / g) is extruded from the trilobal spinneret hole on the spinneret and cooled by ring blowing; wherein, the number of spinneret holes is 24, and the trilobal spinneret The three lobes of the spinneret hole are of unequal width, and are equally spaced on the same circle, and along the clockwise direction, the width of the narrowest lobe is 0.09mm, 0.06mm, 0.07mm, 0.1mm, 0.07mm, 0.08mm, 0.09mm, 0.07mm, 0.1mm, 0.06mm, 0.1mm, 0.08mm, 0.08mm, 0.08mm, 0.12mm, 0.1mm, 0.11mm, 0.07mm, 0.09mm, 0.1mm, 0.1mm, 0.1mm, 0.06mm , 0.09mm, the width of the other two leaves is fixed, and the ratio of the maximum width of the narrowest leaf to the width of the remaining two leaves is 1.0:1.6:1.55, the length of all three leaves is the same, and the ratio of the length to width of t...

Embodiment 3

[0056] A kind of preparation method of coral fleece fabric, its process is as follows:

[0057] (1) Preparation of special-shaped semi-dull polyester drawn yarn:

[0058] (1.1) The PET melt (intrinsic viscosity is 0.64dL / g) is extruded from the trilobal spinneret hole on the spinneret and cooled by ring blowing; wherein, the number of spinneret holes is 24, and the trilobal spinneret The three lobes of the spinneret hole are of unequal width, and are equally spaced on the same circle, and along the clockwise direction, the width of the narrowest lobe is 0.09mm, 0.06mm, 0.12mm, 0.11mm, 0.07mm, 0.06mm, 0.1mm, 0.08mm, 0.1mm, 0.09mm, 0.09mm, 0.09mm, 0.07mm, 0.11mm, 0.12mm, 0.1mm, 0.11mm, 0.07mm, 0.09mm, 0.1mm, 0.1mm, 0.1mm, 0.06mm , 0.09mm, the width of the other two leaves is fixed, and the ratio of the maximum width of the narrowest leaf to the width of the remaining two leaves is 1.0:1.9:1.8, the length of all three leaves is the same, and the ratio of the length to width of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com