A graphite high-temperature cathode device for electric thrusters

A technology for electric thrusters and cathodes, which is applied in the direction of thrust reversers, plasma utilization, machines/engines, etc., can solve the problems of difficult connection process and low working life, and achieve simple assembly process, low cost, and reduced cathode weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below through specific embodiments in conjunction with the accompanying drawings. These embodiments are only used to illustrate the present invention, and are not intended to limit the protection scope of the present invention.

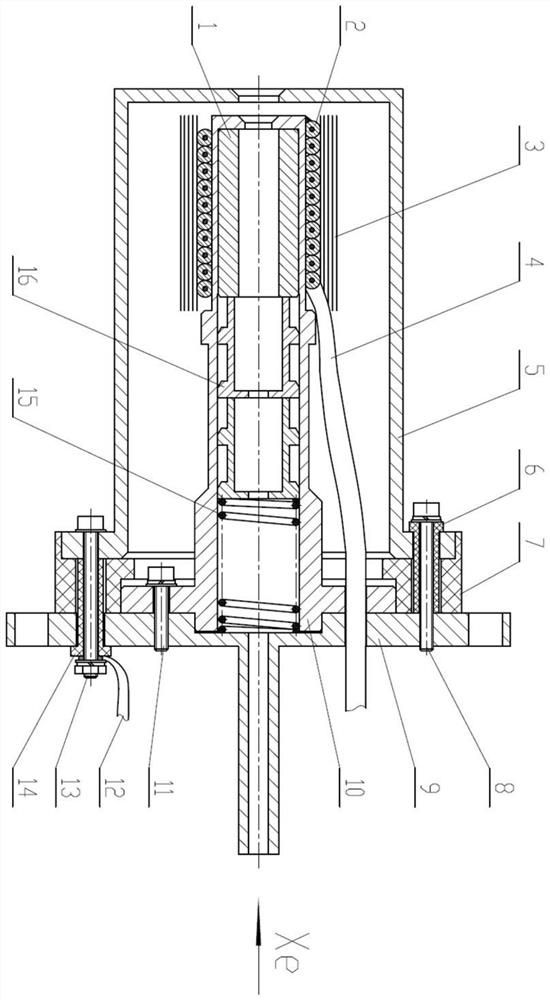

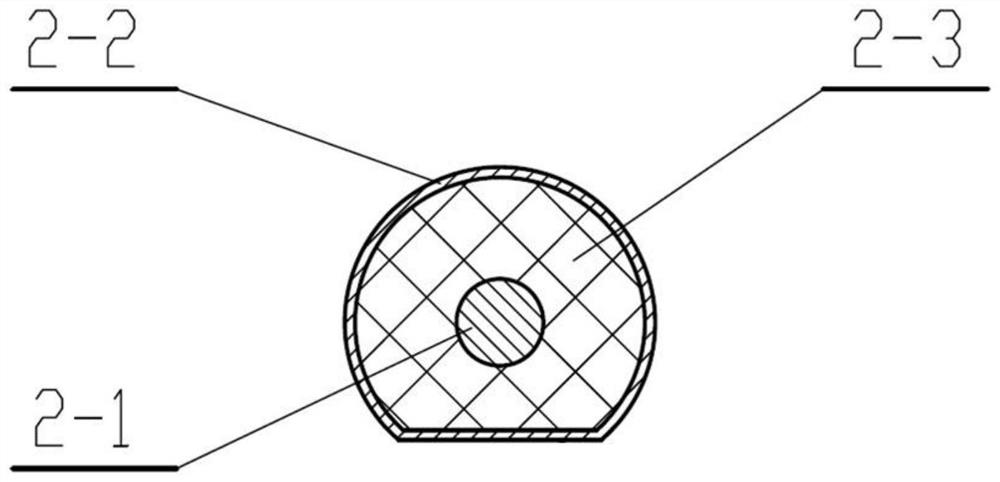

[0039] The present invention is a graphite high-temperature cathode device for an electric thruster, such as figure 1 As shown, it includes a cathode tube 10 , a gas supply flange 9 , a contact electrode 5 , a contact electrode lead 12 , an emitter 1 and a heater 2 .

[0040] The gas supply flange 9 is fixed on the first end of the cathode tube 10 by four cathode tube fixing screws 11, and a hollow channel is arranged in the center; the hollow channel communicates with the cathode tube 10 for passing xenon gas (Xe) through the hollow channel.

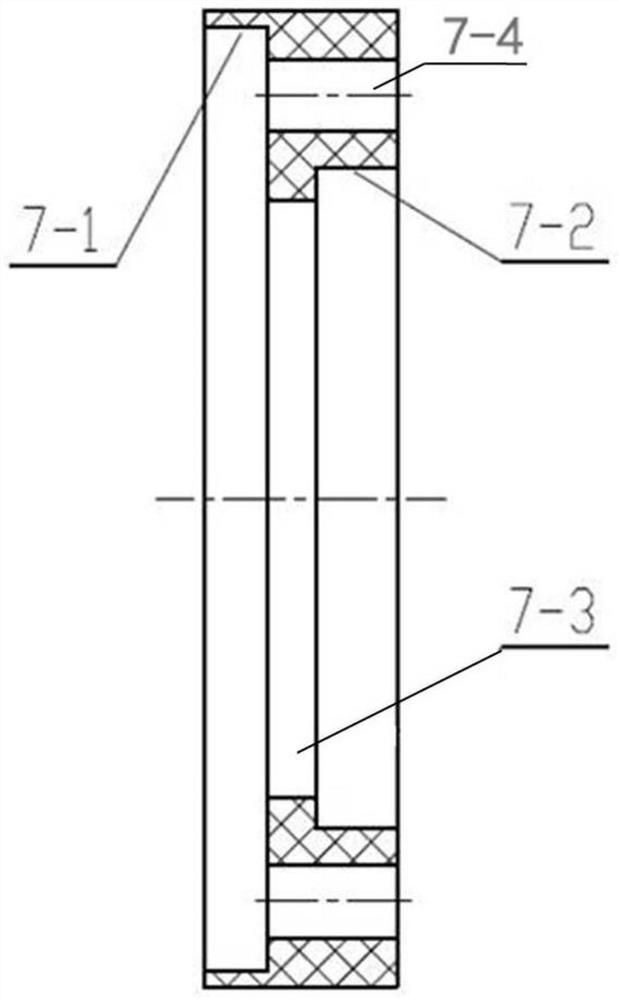

[0041] The contact holder 5 is covered outside the cathode tube 10, and the second end is insulated and connected with the gas supply flange 9 and the cath...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com