A vacuum adsorption connection and binding process of IC card electronic chip and flexible circuit board

A flexible circuit board and electronic chip technology, which is applied in the direction of assembling printed circuits with electrical components, can solve the problems of high energy consumption of IC card electronic chips and radio frequency antennas, difficulty in achieving relevant technical parameters, and inability to re-use wafers, etc. To achieve the effect of guaranteed product quality, low production cost and high conductivity stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

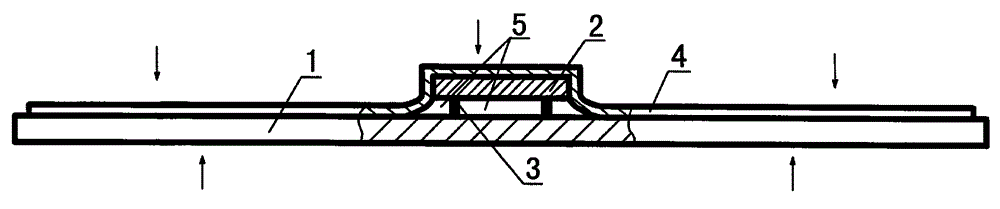

[0019] attached figure 1 Shown is a schematic diagram of the product structure processed by this process.

[0020] as attached figure 1 As shown, a vacuum adsorption connection binding process between an IC card electronic chip and a flexible circuit board is characterized in that the process it adopts is as follows:

[0021] In the first step, the processed and formed flexible circuit board 1 for producing IC cards is placed in a dust-free environment at normal temperature and pressure. In this environment, the contacts on the IC card electronic chip 2 are connected to the flexible circuit board The connection contacts 3 are connected correspondingly to each other, so that the printed circuit (i.e. radio frequency antenna or induction circuit) on the flexible circuit board is conducted with the internal circuit of the IC card electronic chip, in order to make the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com