Hydraulic system for automatic leveling test bench

An automatic leveling and hydraulic system technology, applied in the field of hydraulic systems, can solve the problems of high calorific value of the hydraulic system, lack of test methods, and difficulty in simulating the road spectrum, and achieve the effect of saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

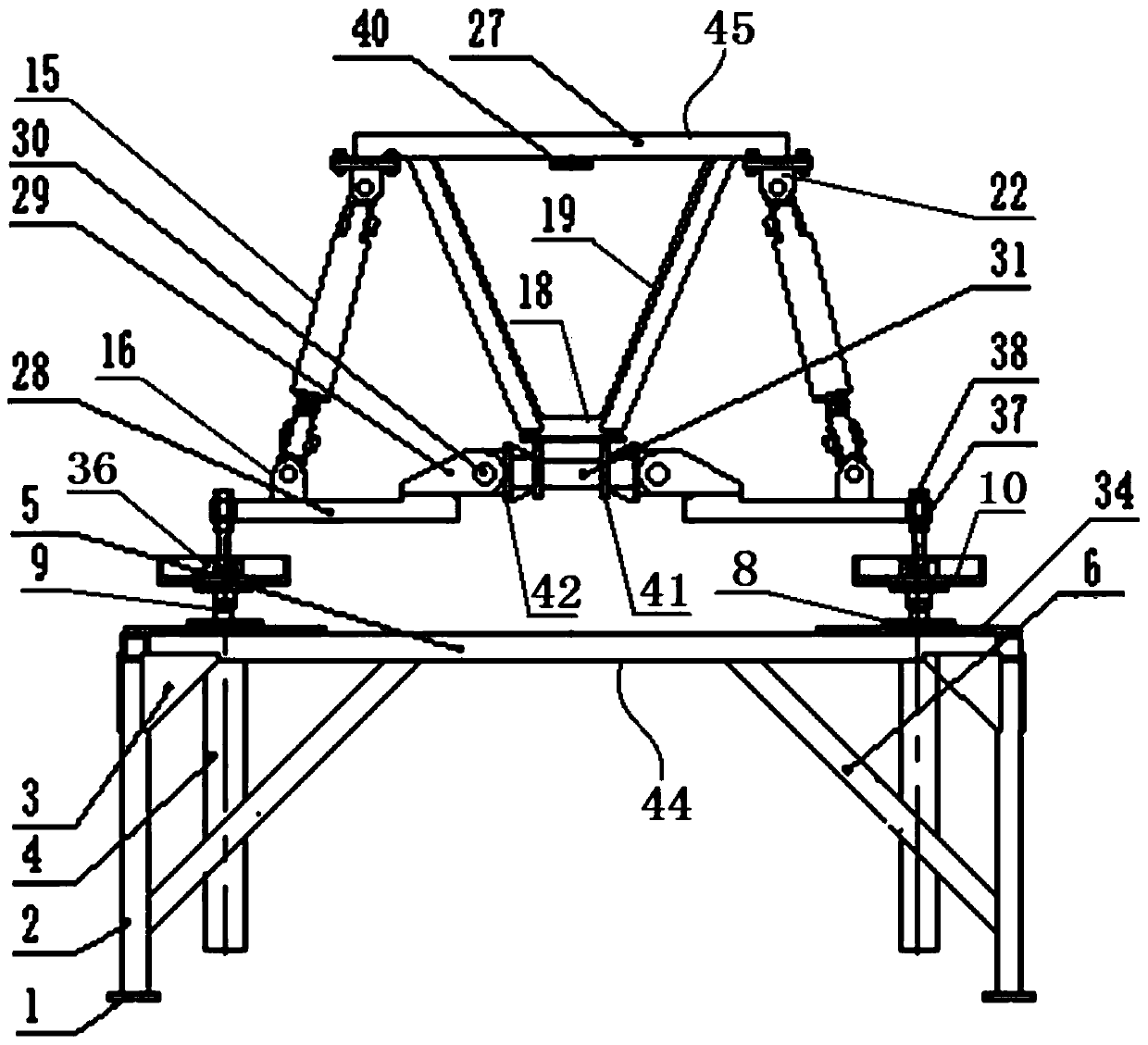

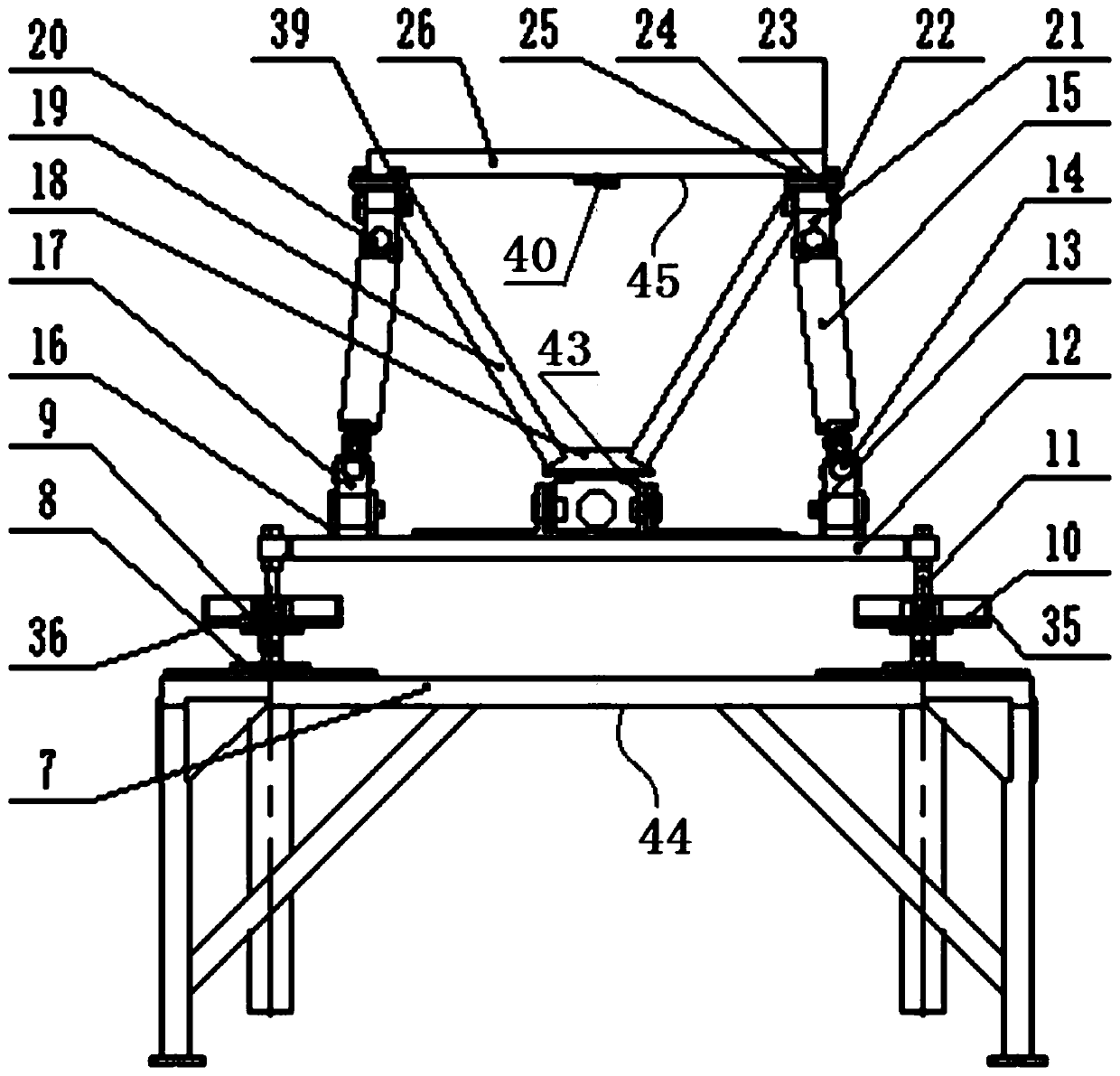

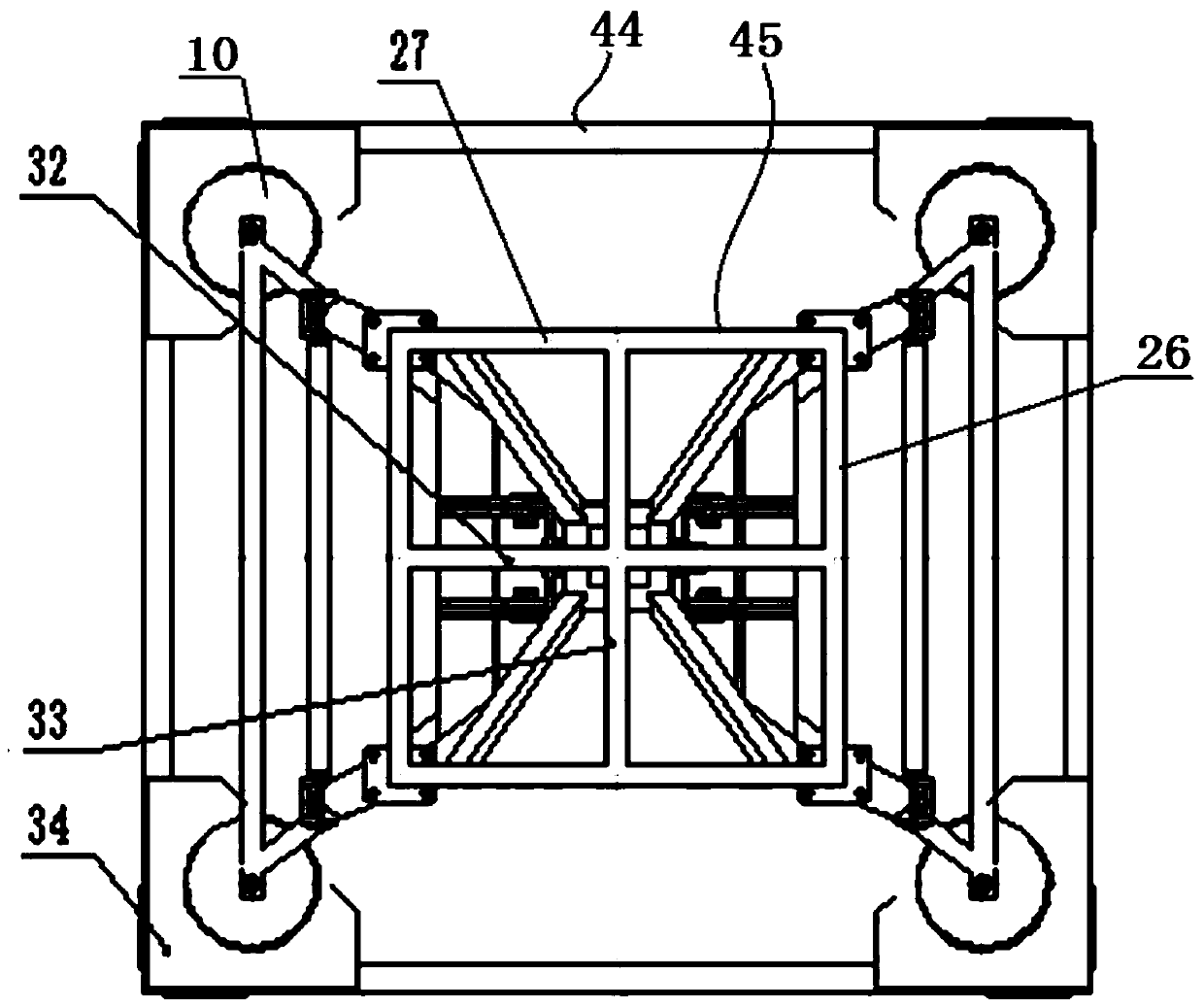

[0025] The present invention will be further described below in conjunction with accompanying drawing.

[0026] like Figure 1 to Figure 4 As shown, a hydraulic system for automatic leveling test bench, including automatic leveling test bench, hydraulic control system and controller;

[0027] The self-leveling test bench includes a lower support frame, four upper support plates 34, four support hydraulic cylinders 4, four bearing discs 10, an upper leveling mechanism, a top support beam a32 and a horizontal inclination sensor 40; The lower support frame is composed of a lower frame 44 and four support legs 2 of equal length. The lower frame 44 is composed of two lower beams a5 correspondingly distributed in the front and rear and two lower beams b7 correspondingly distributed in the left and right. The upper ends of the support legs 2 are fixedly connected to the four corners of the lower frame 44 lower ends respectively; the support legs 2 can be made of square tubes, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com