Garment workshop air quality management system and method

A workshop air and quality management technology, applied in air conditioning systems, heating and ventilation control systems, heating and ventilation safety systems, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

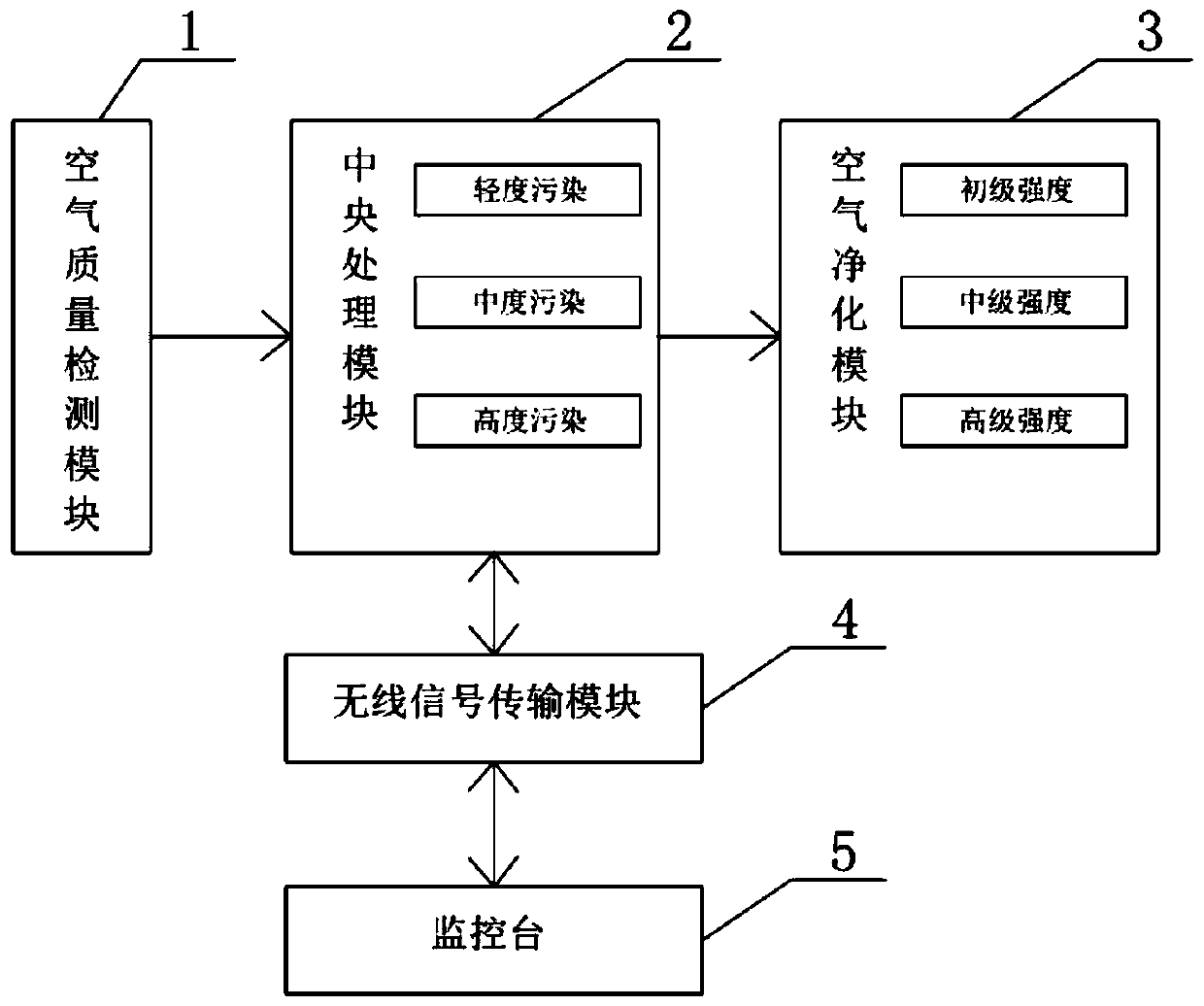

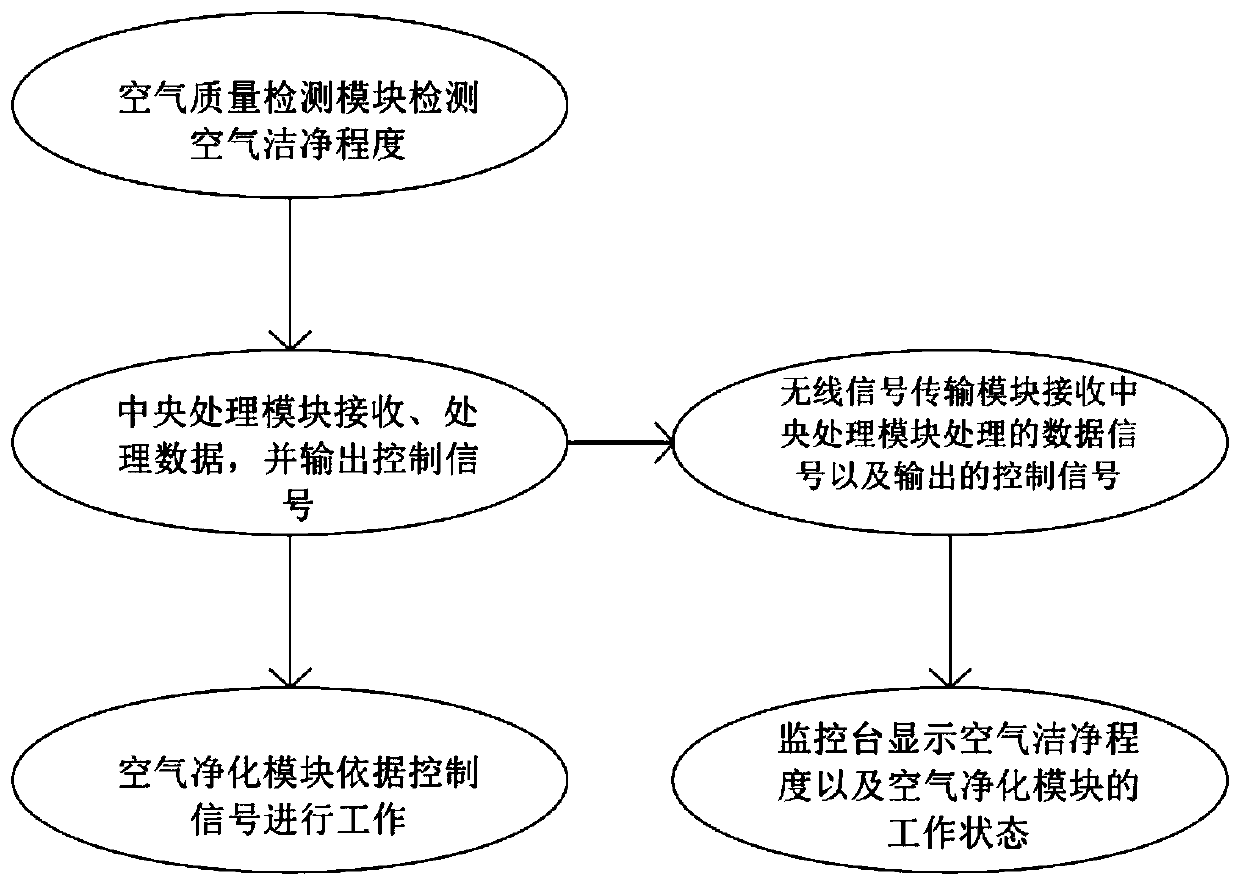

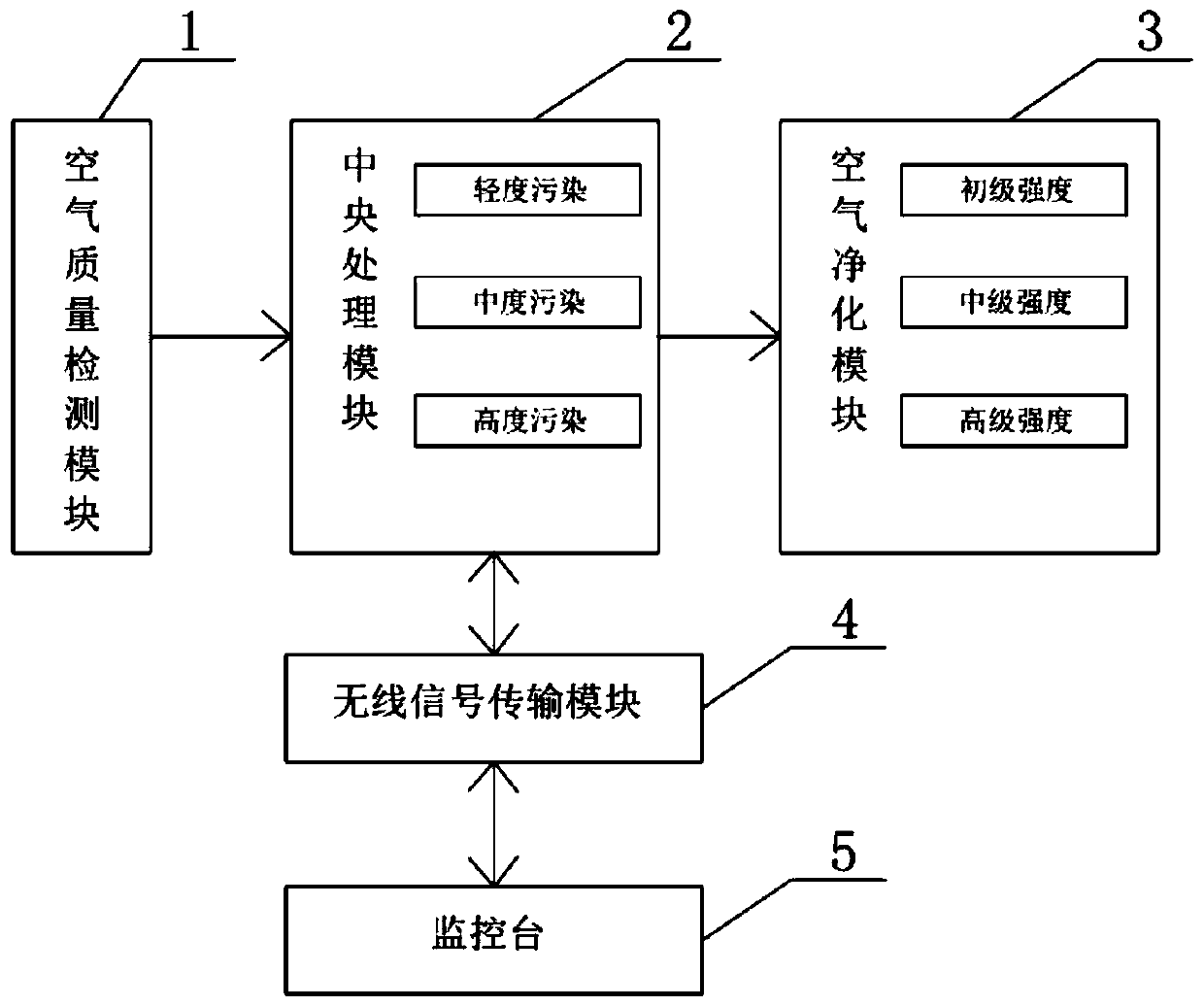

[0033] See figure 1 , An air quality management system for clothing workshops, including clothing workshops. The clothing workshop is provided with multiple groups of areas, and each group of areas is equipped with an air quality detection module 1, a central processing module 2 and an air purification module 3;

[0034] The air quality detection module 1 is used to detect the cleanliness of the air in the corresponding area;

[0035] The central processing module 2 is used to analyze and process data and issue control instructions. The central processing module 2 divides the air cleanliness into different ranges;

[0036] The air purification module 3 is used to perform corresponding tasks according to the instructions issued by the central processing module 2;

[0037] The air quality detection module 1 can transmit the detected air cleanliness signal to the central processing module 2. The central processing module 2 corresponds to the preset range according to the transmitted air c...

Embodiment 2

[0042] See figure 1 , An air quality management system for clothing workshops. In the first embodiment, the central processing module 2 divides the air cleanliness into light pollution, moderate pollution, and high pollution. The central processing module 2 controls the air purification module 3 It is primary intensity, intermediate intensity, and advanced intensity, so that when the air cleanliness level reaches light pollution, the central processing module 2 controls the air purification module 3 to perform primary intensity work, and when the air cleanliness level reaches moderate pollution, the central processing module 2 Control the air purification module 3 to perform intermediate-intensity work. When the air cleanliness level reaches a high level of pollution, the central processing module 2 controls the air purification module 3 to perform advanced-intensity work, so that through the pollution state, the corresponding control air purification module 3 works, While ensur...

Embodiment 3

[0046] See figure 1 , A clothing workshop air quality management system, which is basically the same as the first embodiment. Furthermore, the monitoring station 5 is provided with a security module, and the security module adopts one or a combination of fingerprint module, password module and facial recognition module. This makes it possible to control the monitoring station 5 only after passing the security module certification, which enhances the security performance and avoids non-workers from operating and causing economic losses.

[0047] The monitoring station 5 is provided with a data processing module, which can process each data, so that it can be formulated into a corresponding table display, the display is clearer, and it is convenient for managers to manage air quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com