Drying device and method for vacuum pulsation cold-drying Chinese wolfberries

A technology of vacuum pulsation and drying device, which is used in drying gas arrangement, drying solid materials, non-progressive dryer, etc., to achieve the effect of improving overall quality and improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

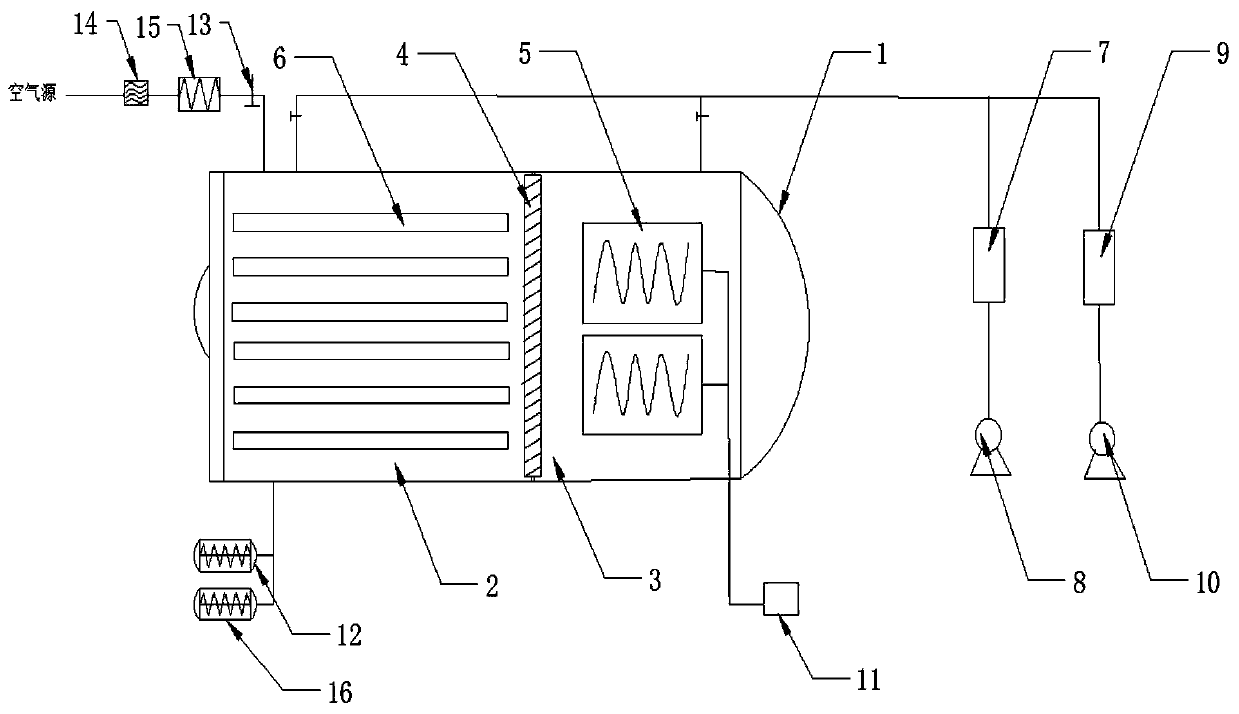

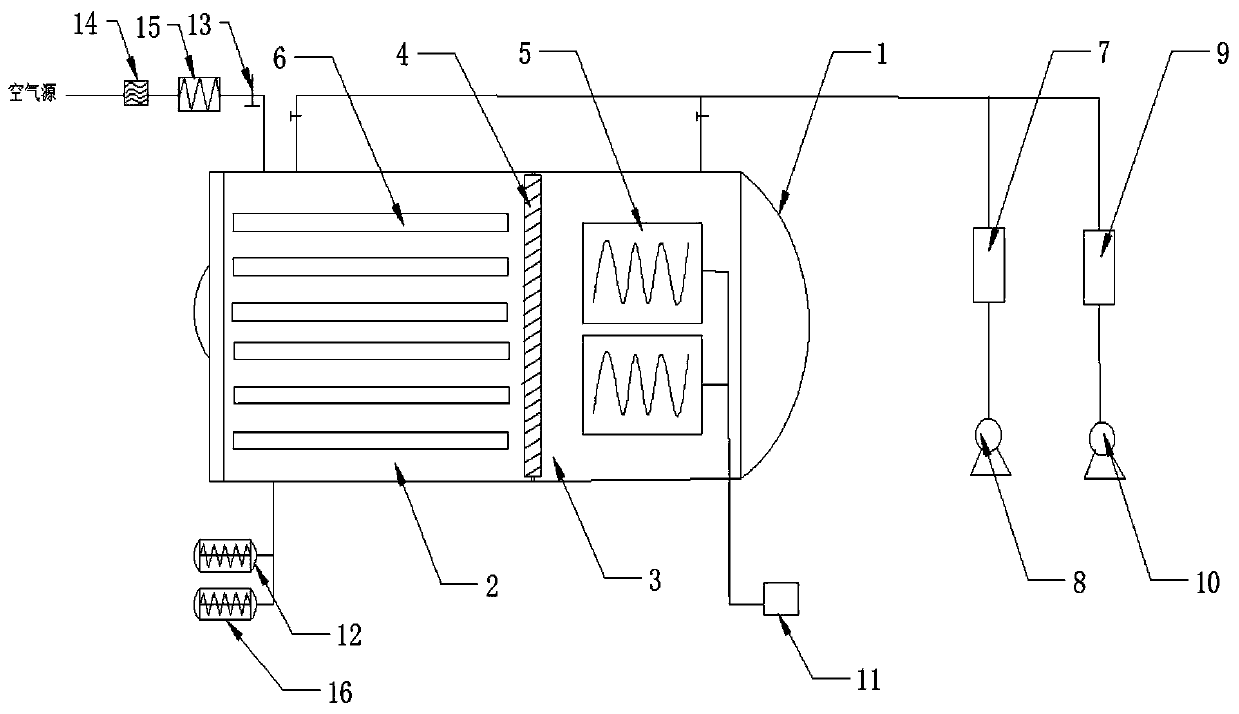

[0097] Example 1 A process for drying wolfberry with a vacuum pulsation cold-drying device, using the device of the present application, comprising the following steps:

[0098] (1) Preheating

[0099] Lycium barbarum fresh fruit is placed in the drying chamber 2, and the temperature of the plate layer 6 of the drying chamber 2 is set;

[0100] Wherein, the temperature of the plate layer 6 is 55°C.

[0101] (2) Vacuum pulsation

[0102] Open the partition plate 4, evacuate the water ring pump 8, evacuate the Roots pump 7, and cold trap 5, and set the range of pulsating vacuum;

[0103] When the lower limit of pulsating vacuum is reached, turn off the evacuation Roots pump 7 and the evacuation water ring pump 8 in sequence, turn on the maintenance water ring pump 10 and maintenance Roots pump 9, and set the maintenance time one;

[0104] Reach maintenance time one, open dehumidifier 14, heater two 15, intake valve 13 and carry out aeration;

[0105] When the upper limit o...

Embodiment 2

[0114] With embodiment 1, the difference is that,

[0115] In step (1), the temperature of the plate layer 6 is 50°C.

[0116] In step (2), the temperature of the cold trap 5 is-45°C; the maintenance time one is 15min, and the maintenance time two is 5min; the number of vacuum pulses is 20 times, and the gas used during aeration is clean nitrogen; The temperature is 45°C, and the relative humidity is ≤45%RH.

[0117]In step (3), vacuum freeze-drying is carried out in stages, and the vacuum degree of vacuum freeze-drying is 400 Pa; when drying, the temperature of the plate layer is 55° C., and the drying time is 5 hours.

Embodiment 3

[0119] With embodiment 1, the difference is that,

[0120] In step (1), the temperature of the plate layer 6 is 60°C.

[0121] In step (2), the temperature of the cold trap 5 is-25°C; the maintenance time one is 18min, and the maintenance time two is 8min; the number of vacuum pulses is 15 times, and the gas used during aeration is clean air; The temperature is 40°C, and the relative humidity is ≤45%RH.

[0122] In step (3), vacuum freeze-drying is carried out in stages, and the vacuum degree of vacuum freeze-drying is 50 Pa; when drying, the temperature of the plate layer is 55° C., and the drying time is 4 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com