Energy-saving domestic architecture with cast-in-place industrial gypsum bearing wall and manufacturing method thereof

A technology for industrial gypsum and residential construction, applied in the direction of residential construction, construction, building components, etc., can solve the problems that the wall cannot be used as a load-bearing wall, is not suitable for use in rural buildings, and is difficult to apply on a large scale. Weight, product quality and construction quality assurance, the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but not as a basis for any limitation of the present invention.

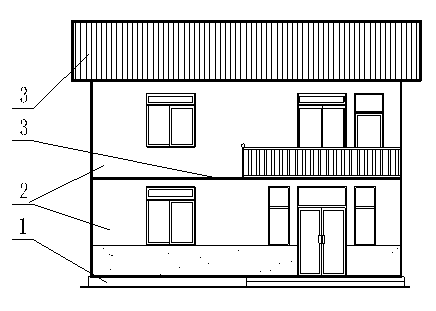

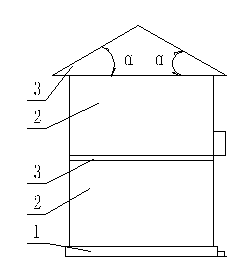

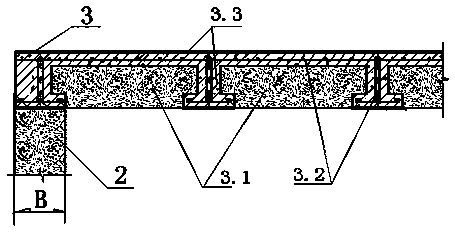

[0020] Embodiments of the present invention: a manufacturing method of a cast-in-situ industrial gypsum load-bearing wall energy-saving residential building of the present invention is to directly adopt existing industrial gypsum as the load-bearing wall material, add water to the industrial gypsum at the construction site and stir it into a slurry, When mixing industrial gypsum with water to form a slurry, the amount of water added can be controlled at 0.5 to 2 times the amount of gypsum. The prepared slurry only needs to flow naturally during pouring, and then it can be used on the foundation of the completed residential building. 1. Set up the wall formwork according to the traditional method of pouring concrete walls, and pour the industrial gypsum slurry directly into the wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com