Geotechnical engineering inclinometry method and device based on shape memory material

A memory material, geotechnical engineering technology, applied in measuring devices, measuring inclination, mapping and navigation, etc., can solve the problem of lack of monitoring ability of true three-dimensional horizontal displacement characteristics of rock and soil, inability to operate instruments correctly, time-consuming and laborious data collection, etc. It can meet the needs of large deformation monitoring, reduce the workload of monitoring operations, and reduce the cost of production and operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

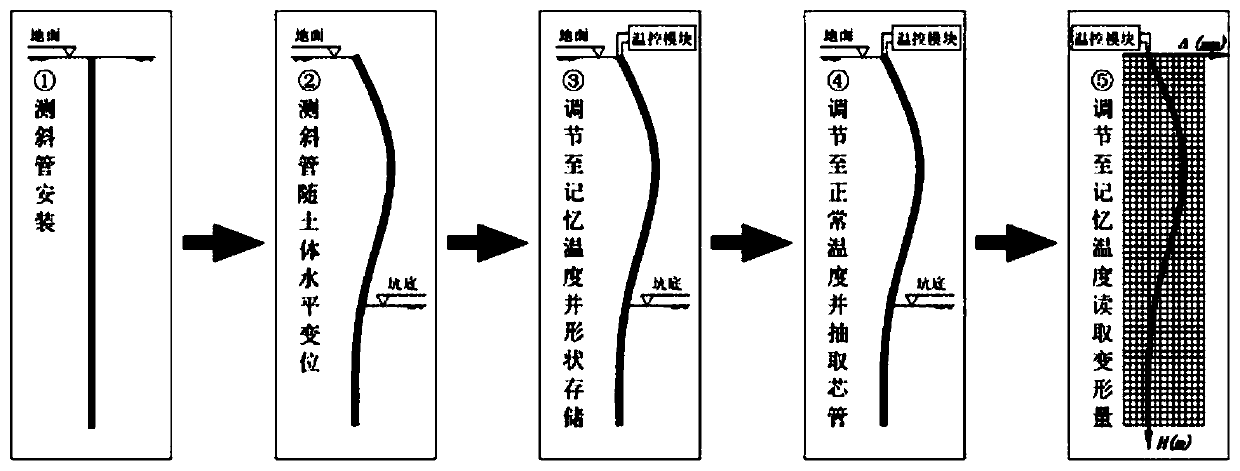

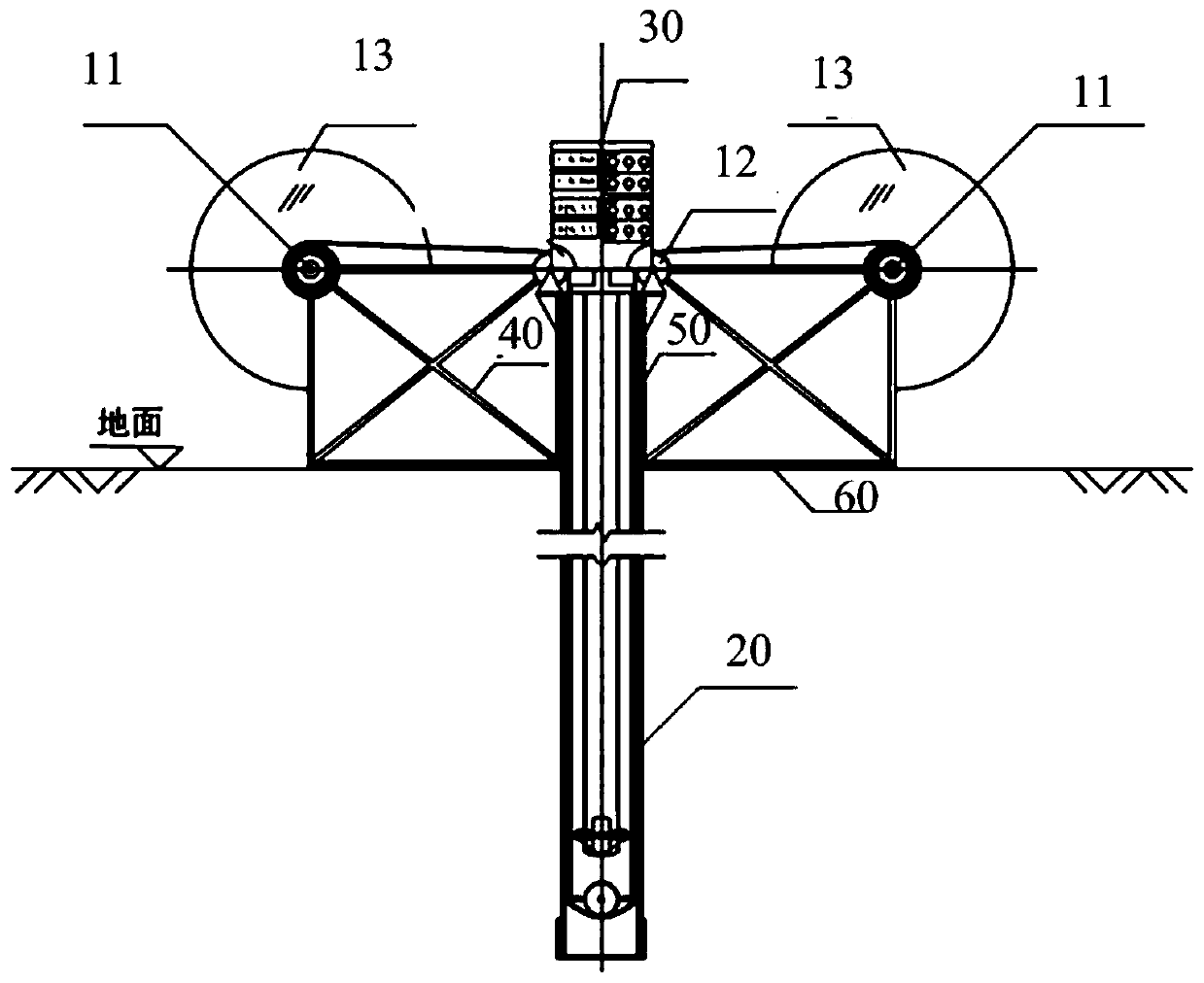

[0047] Combine below Figure 1 to Figure 7 , which describes in detail the geotechnical engineering inclination measuring method and device based on the shape memory material of the present invention.

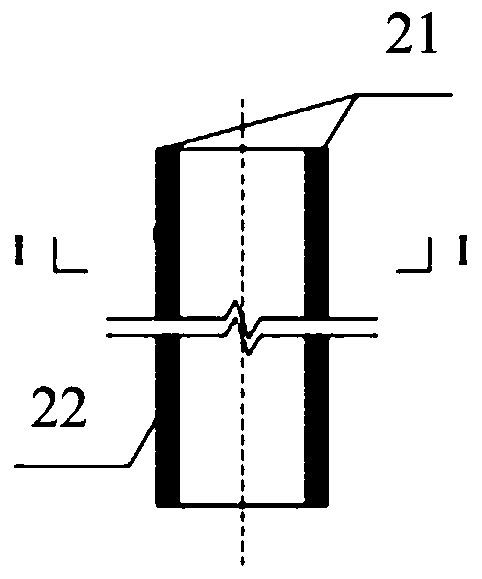

[0048] Please refer to Figure 2 to Figure 7 , a geotechnical engineering inclinometer device based on shape memory materials, comprising a measuring strip, a core tube 22, an inclinometer tube 20, a shape-forming condition control module 30, and a drive unit, and the inclinometer tube 20 is pre-embedded before the monitoring work is carried out In the formation, the inner wall of the inclinometer pipe 20 is provided with a temperature-controlled chamber 22, and the temperature-controlled chamber 22 is provided with a measuring strip cavity 23, which is used for placing a measuring strip made of shape memory material. The measuring strip is wrapped in the core tube 22, which can adjust the forming conditions of the measuring strip. The core tube 22 is built in the inclinometer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com