Image forming method

An image and resin layer technology, which is applied in the direction of instruments, developers, optics, etc., can solve the problems of economical unfeasibility and achieve the effect of excellent image durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0173] As a method for preparing a polyester resin dispersion, for example, a method of dispersing in an aqueous medium without using a solvent; dissolving a polyester resin in a solvent to prepare a solution, and adding an aqueous solution to the solution After the medium, the method of desolvation treatment, etc. In the present invention, the latter method is preferred. The solvent used in the latter method is not particularly limited, and examples thereof include isopropanol, butanol, methyl ethyl ketone, and the like.

[0174] Among them, the so-called "aqueous medium" refers to a medium containing at least 50% by mass of water, and as components other than water, organic solvents dissolved in water can be mentioned, such as methanol, ethanol, isopropanol, butane, etc. Alcohol, acetone, dimethylformamide, methyl cellosolve, tetrahydrofuran, etc. Among these, alcohol-based organic solvents such as methanol, ethanol, isopropanol, and butanol, which are organic solvents tha...

Embodiment 1-1~20-1、 comparative example 1-1

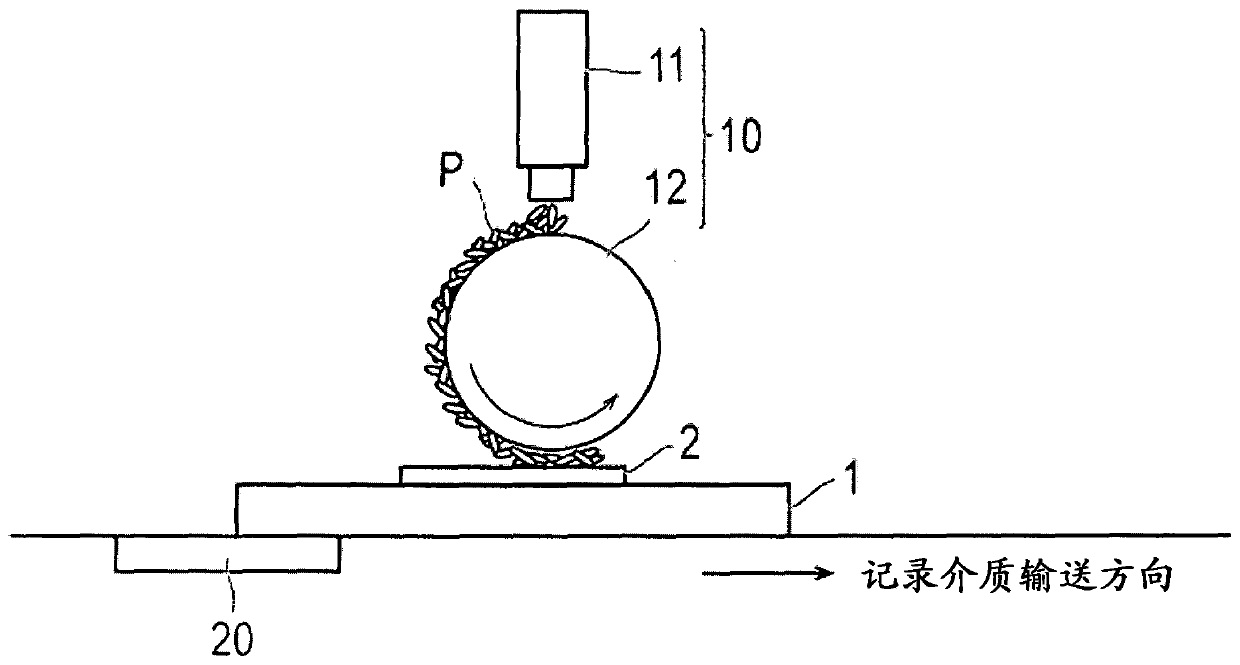

[0508] Each developer and Oji Paper POD GLOSS COAT (weight per square meter 128g / m 2 ), output a resin image (thickness 5 μm) having a square patch pattern of 2 cm×2 cm on a recording medium. The above-mentioned resin-made image appears black (black).

[0509]Then, on a hot plate heated to 60° C., the above-mentioned resin image was placed upward, and the recording medium was placed, and after 30 seconds, powder 1 (Sansherin Bebi-D-9 chromium powder, GG Corp. Co., Ltd. Manufactured, flat shape, particle size 25-40 μm), left still for 30 seconds, and a decorative image was obtained. Compressed air of 0.30 MPa was sprayed to this decorative image, and the adhesiveness of the powder 1 was confirmed. When the powder came off from the resin image, the surface temperature of the hot plate was raised by 1° C., and the powder decorative image was formed in the same manner as above, and the adhesion of the powder 1 was confirmed in the same manner. The surface temperature of the ho...

Embodiment 1-2

[0517] A resin image (thickness: 5 μm) having a square patch pattern of 2 cm×2 cm was output on a recording medium in the same manner as in the aforementioned .

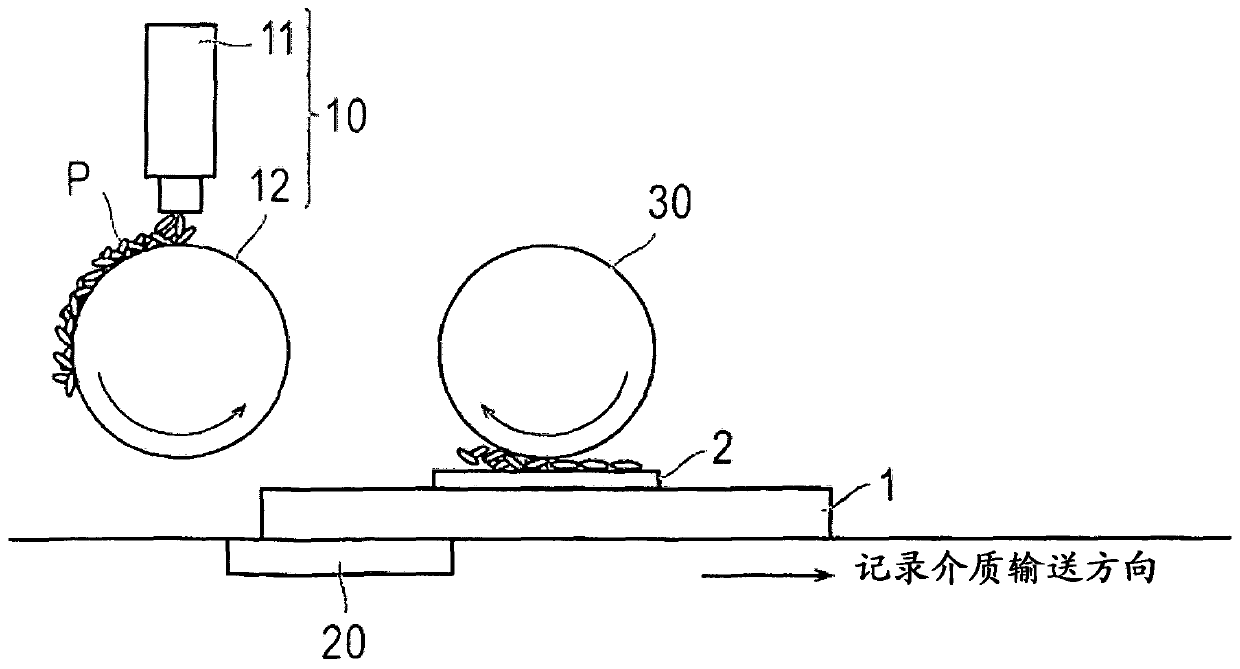

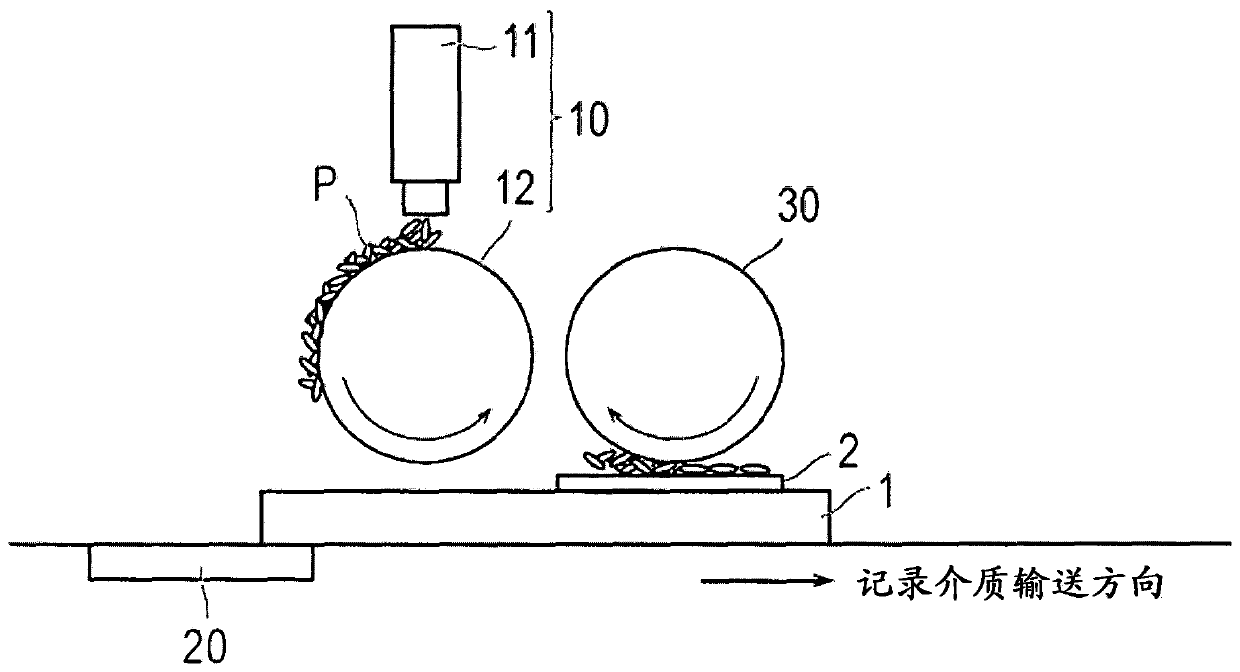

[0518] Next, on a hot plate heated to 85° C., place the above-mentioned resin image upwards and place the recording medium, and after 30 seconds, sprinkle powder 1 (Sanshin Bebe D-9 chromium powder, manufactured by GG Corp. Co., Ltd., on the resin image) flat metal powder), the surface of the patch image of the above-mentioned resin image was subjected to sliding rubbing with a sponge roller. The squeezing force at the time of sliding friction is about 10 kPa. After the sliding rubbing, the above-mentioned resin image was cooled at room temperature, and the remaining powder 1 was removed from the surface of the image with a brush to form a decorative image. 10 test subjects visually observed the decorative image and evaluated whether they felt a sufficient metallic feeling. Five or more people who answered that the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com