Lead-free component interconnection welding spot tin whisker touch risk assessment method

A technology for risk assessment and components, applied in the direction of design optimization/simulation, etc., can solve the problems of difficult extraction of tin whisker parameters, no model describing the growth of tin whiskers over time, and no clear evaluation method, etc., and achieves great application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] Step 1: Conduct tin whisker growth stimulation test.

[0094] The test sample is a copper plate (red copper T2) with a thickness of 5μm pure tin (purity ≥99.0%), the test stress condition is 60℃, 95%RH, and the surface of the test sample is observed with a scanning electron microscope (SEM) every 10 days .

[0095] Step 2: Determination of characteristic parameters of tin whiskers.

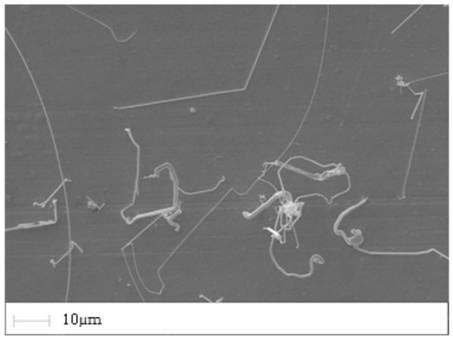

[0096] After 20 days of the test, a large amount of tin whiskers grew, Figure 7 Schematic diagram of tin whiskers grown by scanning electron microscope (SEM).

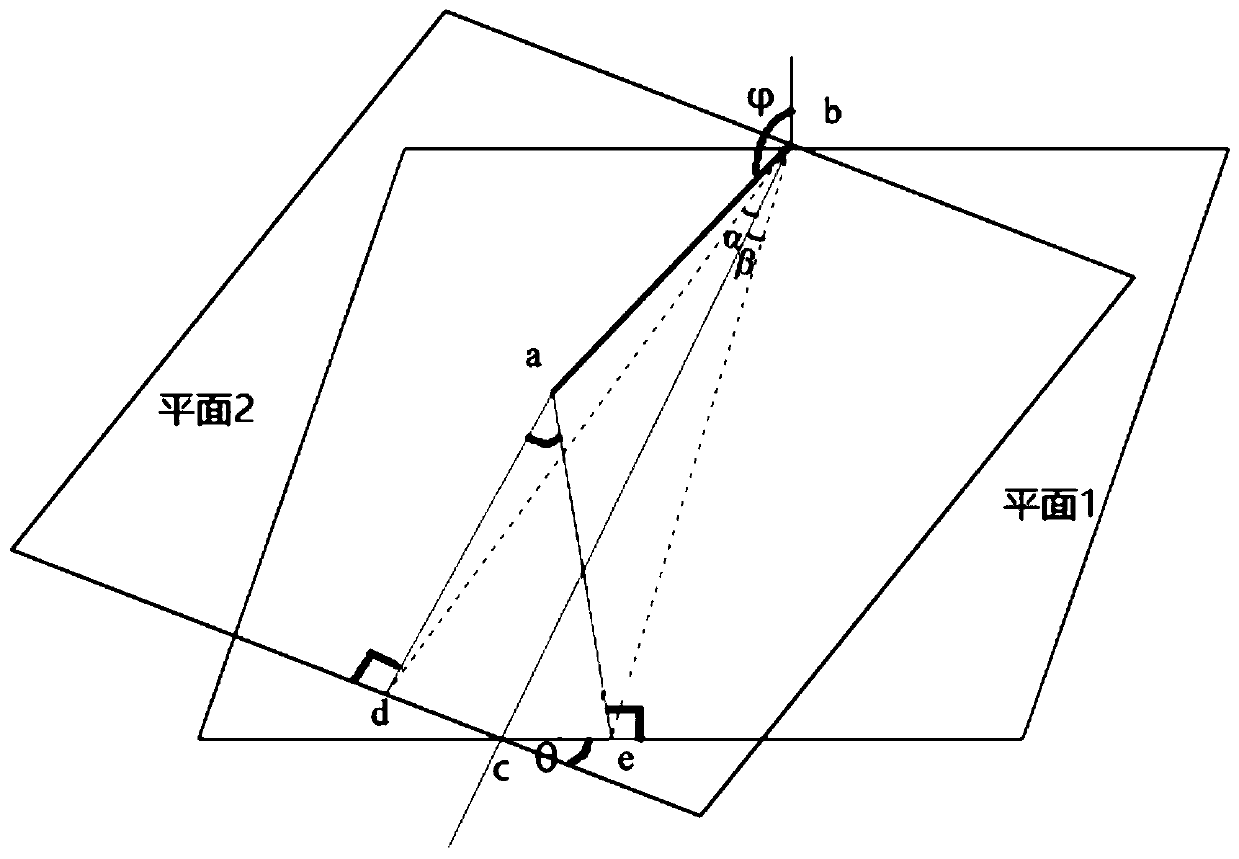

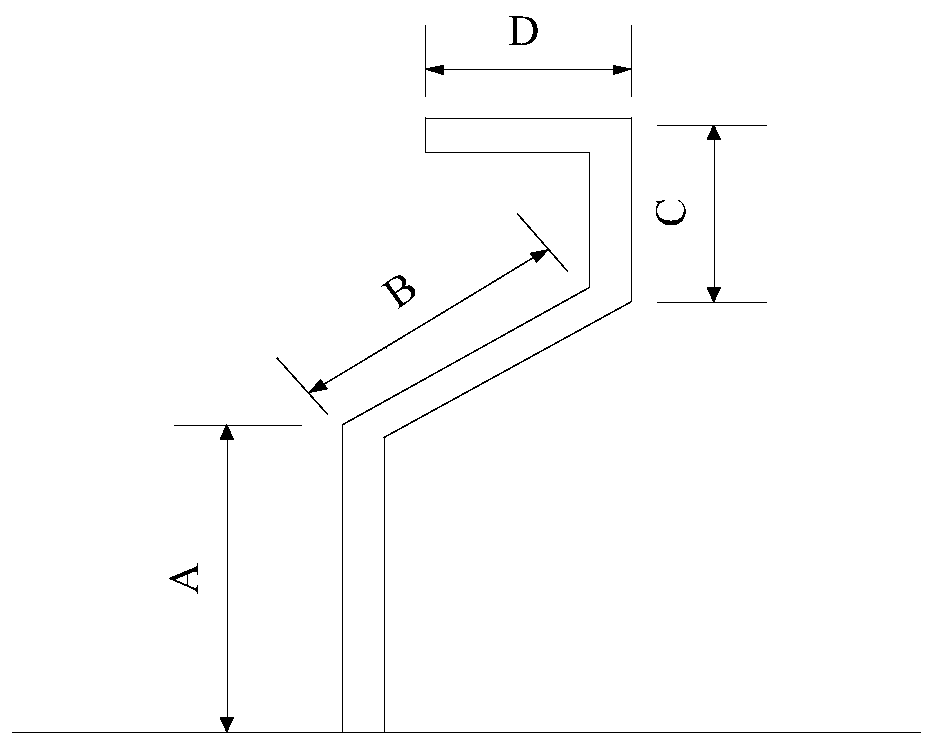

[0097] According to the proposed measurement method of tin whisker growth length, growth density, and growth angle, use SEM to measure and record the growth length distribution of tin whiskers as shown in Table 2, the growth density distribution of tin whiskers is shown in Table 3, and the growth angle of tin whiskers The distribution is shown in Table 4.

[0098] Table 2 Growth length distribution of tin whiskers

[0099]

[0100]

[0101]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com