Method for removing metal ions in electrode material and supercapacitor

A supercapacitor, metal ion technology, applied in hybrid capacitor electrodes, non-metallic elements, chemical instruments and methods, etc., can solve the problems of uneven particle size distribution, a large amount of acid-containing wastewater, and short device life, and achieve low process efficiency. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

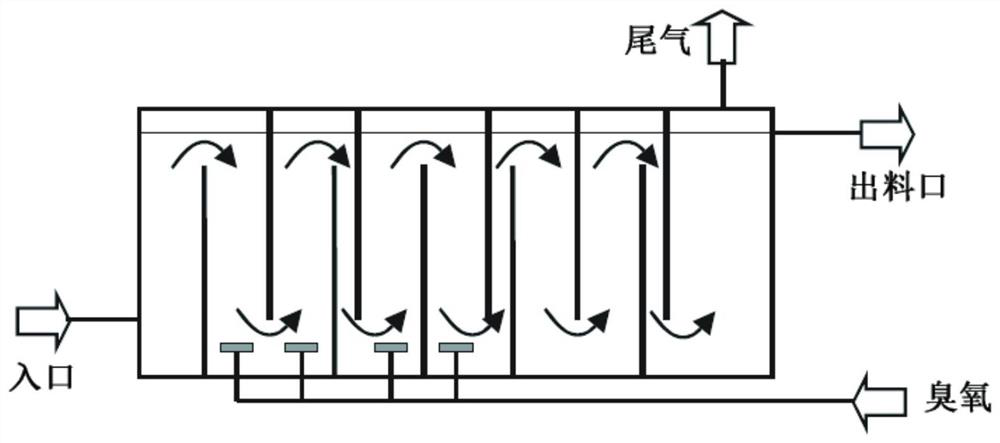

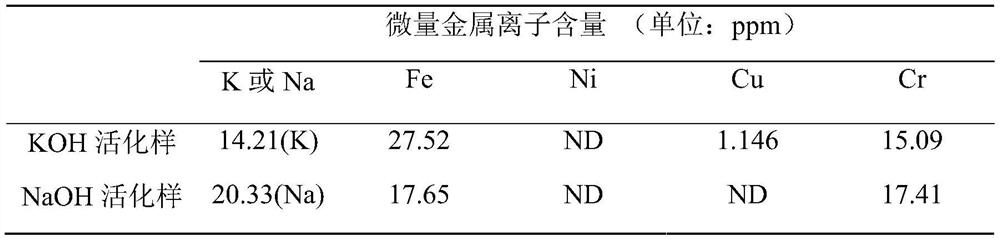

[0068] Wood activated carbon activated by potassium hydroxide or sodium hydroxide was neutralized with dilute nitric acid (concentration) to a surface pH value of 7.0, and then prepared with deionized water to form a water carbon slurry with a solid content of 20 wt%. The ratio of the amount of ozone used in the ozonation process to the volume of the water-charcoal slurry was 1.2 mg / L, and the contact time between the ozone / air flow and the water-charcoal slurry was 20 minutes. The temperature range of the heat treatment of the oxidized water-carbon slurry is 85°C, and the treatment time is 45 minutes. Press filtration removes most of the water without further drying, and the wet sample is directly reconstituted with deionized water to make a water-charcoal slurry. Repeat the ozonation and heat treatment once. The treated carbon material was press-filtered, dried, and then heat-treated at 650° C. for 120 minutes under a nitrogen atmosphere. The content of various metal ions ...

Embodiment 2

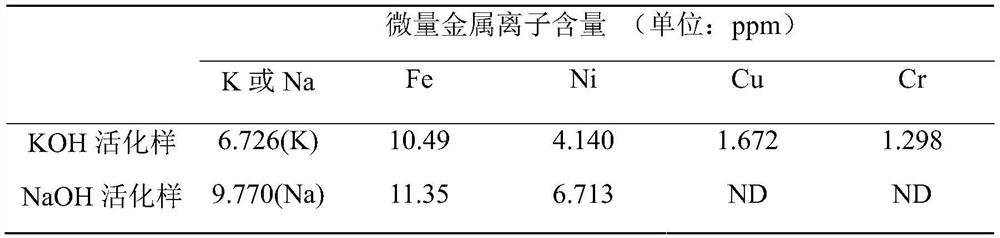

[0073] Coconut shell activated carbon activated by potassium hydroxide or sodium hydroxide is neutralized with dilute nitric acid (concentration) to a surface pH value of 7.0, and then prepared with deionized water to form a water-charcoal slurry with a solid content of 20 wt%. The ratio of the amount of ozone used in the ozonation process to the volume of the water-charcoal slurry was 1.2 mg / L, and the contact time between the ozone / air flow and the water-charcoal slurry was 20 minutes. The temperature range of the heat treatment of the oxidized water-carbon slurry is 85°C, and the treatment time is 45 minutes. Press filtration removes most of the water without further drying, and the wet sample is directly reconstituted with deionized water to make a water-charcoal slurry. Repeat the ozonation and heat treatment once. The treated carbon material was press-filtered, dried, and then heat-treated at 750° C. for 60 minutes under a nitrogen atmosphere. The content of various me...

Embodiment 3

[0078] The coal-based activated carbon activated by potassium hydroxide or sodium hydroxide is neutralized with dilute nitric acid (concentration) to a surface pH value of 7.0, and then prepared with deionized water to form a water-carbon slurry with a solid content of 20 wt%. The ratio of the amount of ozone used in the ozonation process to the volume of the water-charcoal slurry was 1.2 mg / L, and the contact time between the ozone / air flow and the water-charcoal slurry was 20 minutes. The temperature range of the heat treatment of the oxidized water-carbon slurry is 85°C, and the treatment time is 45 minutes. Press filtration removes most of the water without further drying, and the wet sample is directly reconstituted with deionized water to make a water-charcoal slurry. Repeat the ozonation and heat treatment once. The treated carbon material was press-filtered, dried, and then heat-treated at 850° C. for 30 minutes under a nitrogen atmosphere. The content of various met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com