Probiotic microcapsule and preparation method thereof

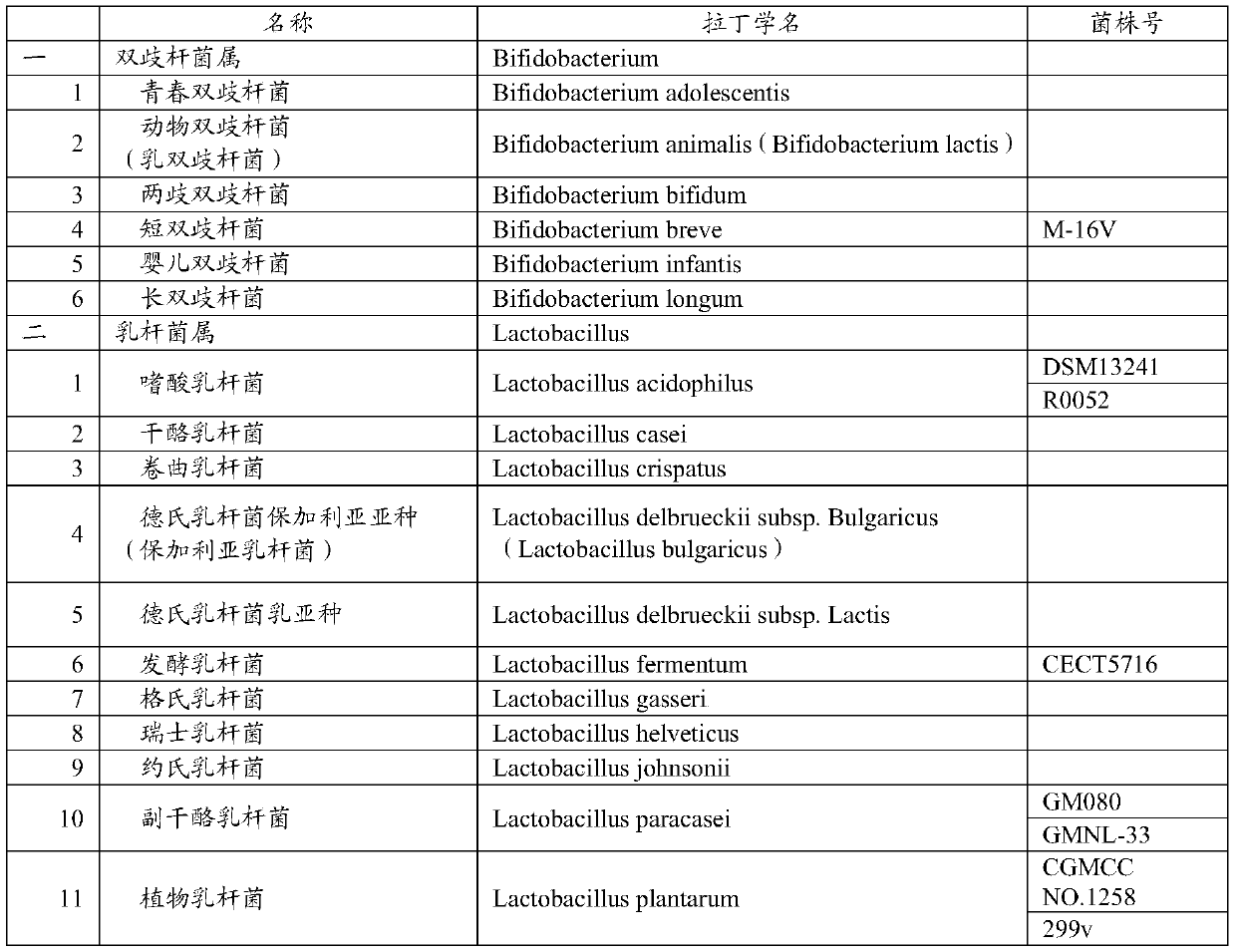

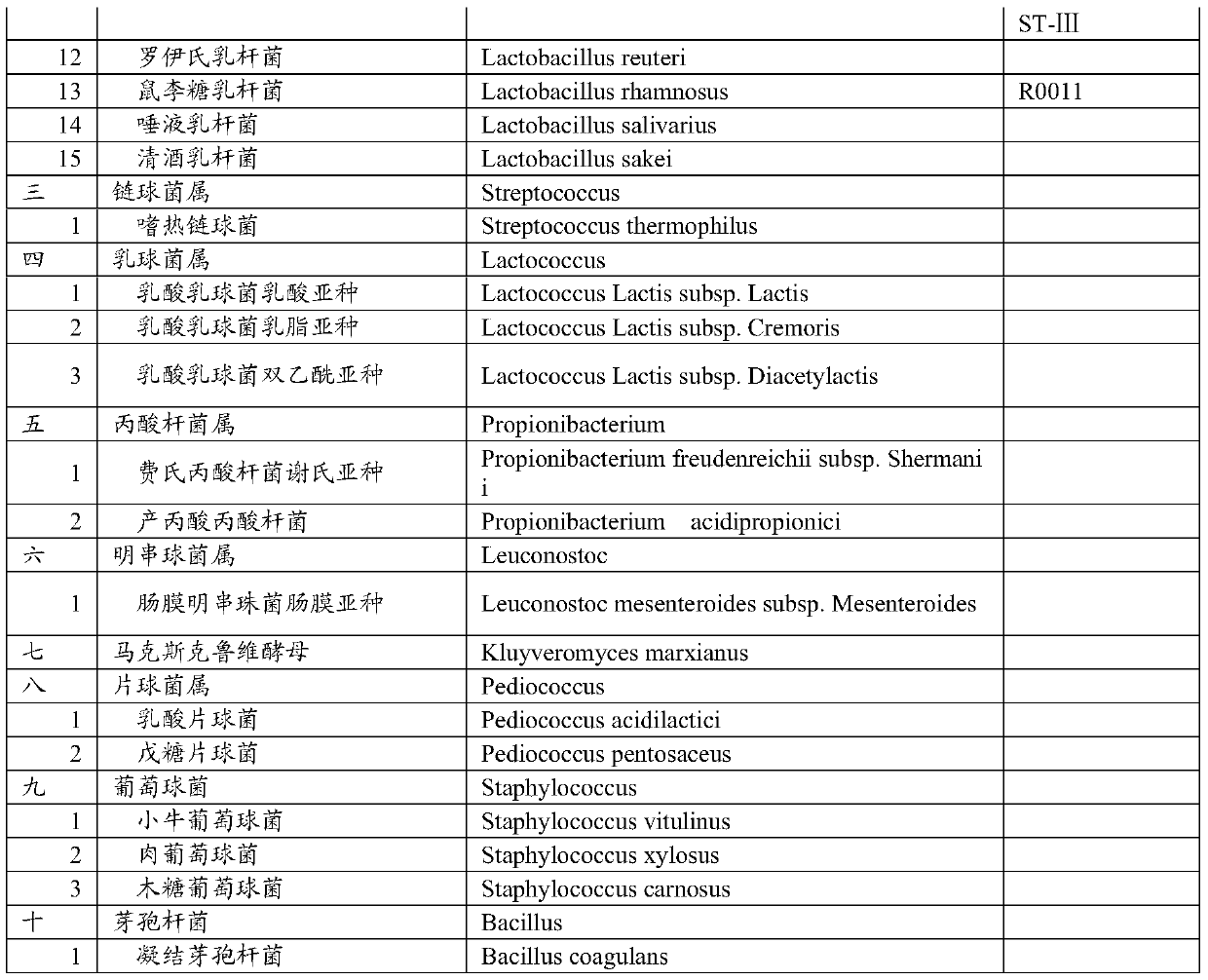

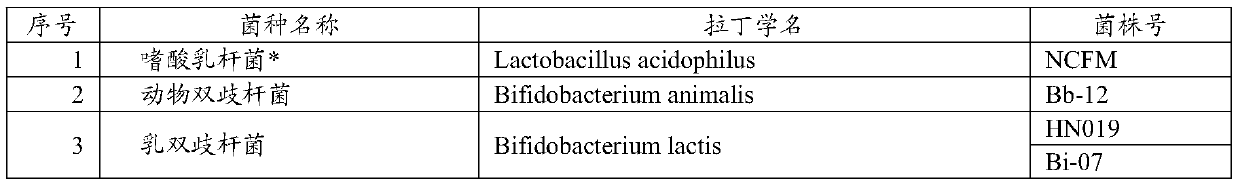

A technology of microcapsules and probiotics, applied to bacteria, lactobacilli, bifidobacteria and other directions used in food preparation, can solve the problems of harsh application conditions, inability to effectively exert probiotic effects, and reduction in the number of probiotics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0120] In one aspect of the present invention, the present invention also relates to a preparation method of probiotic microcapsules, the probiotic microcapsules have one or more layers of embedding structure, including: bacterial core particles and optional at least one layer of encapsulation Cover the shell of the bacterium core particle, wherein the bacterium core particle includes a core material and a first layer of wall material, the core material includes one or more probiotic powders or bacterium slime, the core material is covered by the Covered by the first layer of wall material, and the at least one shell covering the core particles includes one layer, two or more layers of wall material, which are respectively the second layer of wall material and the third layer of wall material or more layers of wall materials;

[0121] Optionally, the above-mentioned core particles also include a binder;

[0122] The preparation of above-mentioned probiotic microcapsules compr...

Embodiment 1~3

[0173] Embodiment 1~3 and comparative example thereof

Embodiment 1

[0175] 1. Raw materials (based on 1000g dry microcapsules)

[0176] WPI 750g (concentration 11%);

[0177] Water 6068g;

[0178] Bacillus coagulans powder 250g;

[0179] The curing agent solution is 6818ml, the concentration is 0.5mol / L, wherein: the curing agent is a mixed solution of sodium acetate, glacial acetic acid and Tween-20. Sodium acetate is 137g, glacial acetic acid is 100ml, Tween-20 is 2.9g, water is 6718g.

[0180] 2. Preparation method

[0181] a. Mix whey protein with water and stir at 180rpm / min at 4°C for 16 hours;

[0182] b. heat-treat the whey protein solution at 78°C, 95rpm / min, and 45 minutes;

[0183] c. Cool immediately at 0°C; store at 4°C for 12 hours;

[0184] d. Mix 137g of sodium acetate, 100ml of glacial acetic acid and 6718g of water to make a curing agent solution, adjust the pH to 4.6, add 2.9g of Tween-20, mix well and set aside.

[0185] e. Granulation: uniformly mix and granulate the above-mentioned pretreated WPI and the probiotic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com