Thermoplastic elastomer non-woven fabric material and machining process

A thermoplastic elastomer, processing technology, applied in non-woven fabrics, textiles and papermaking, heating/cooling fabrics, etc., can solve the problems affecting the yield of non-woven fabrics, large volume of conveyor belts, low energy efficiency and utilization rate, etc. Competitiveness, not easy to tear and deform, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

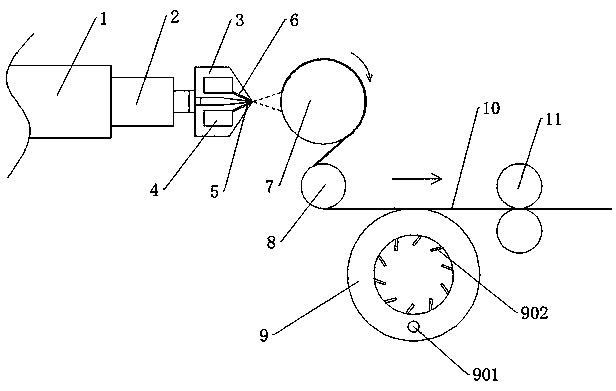

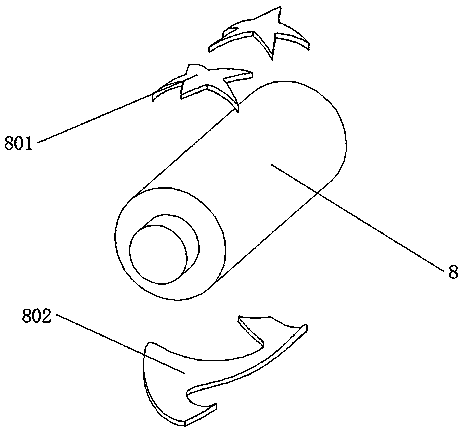

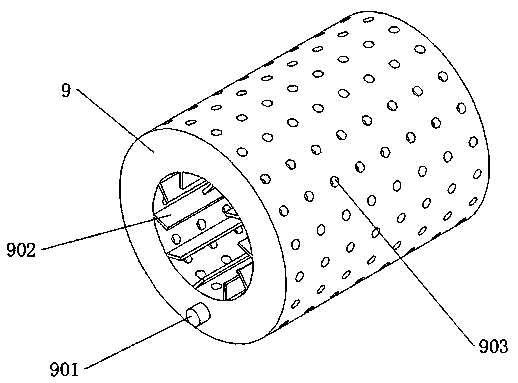

[0035] see figure 1, thermoplastic elastomer non-woven fabric material and processing technology, including a processing equipment rack, a melting extruder 1 is fixedly connected to the processing equipment rack, and the melting extruder 1 includes a heating sheet, a temperature sensing head and a control board, and the control board can The melting temperature in the melt extruder 1 is controlled at 200 degrees Celsius, and the non-Newtonian exponent n of the polyurethane melt shows a peak value as the temperature rises. When the temperature rises to 200 degrees Celsius, n reaches a maximum value of 0.85, which is close to the rheology of a Newtonian fluid The behavior is not easy to make the viscosity fluctuate too much, and it is not easy to affect the quality of the non-woven fabric 10. The extrusion end of the melt extruder 1 is fixedly connected to the metering pump 2, and the output end of the metering pump 2 is fixedly connected to the melt blowing head 3. The processin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com