High-energy-level protective steel shed tunnel suitable for any terrain in mountainous area

A high-energy, steel shed technology, used in protective equipment, buildings, etc., can solve the problems of rockfall breakdown, lack of protection, and small collapse at high altitudes, and achieve the effect of enhancing buffer capacity and improving rockfall protection performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Such as figure 1 As shown, the present invention is suitable for a high-energy protective steel shed tunnel in any terrain in mountainous areas, including a steel shed cave body 1, and a rotating support 2 is arranged on the side of the roof of the steel shed cave body 1, and the rotating support 2 is connected to a The bottom of the piston spring strut 3 is connected, and the top of the piston spring strut 3 is connected with a pulley 4. A flexible protective net 5 is arranged above the steel shed cave body 1, and one side of the flexible protective net 5 is fixed on the top plate of the steel shed cave body 1. The side of the mountain and the other side are connected with a stay rope 6, and the stay rope 6 is anchored in the side slope 7 around the pulley 4, and the end of the stay rope 6 close to the side slope 7 is provided with a decompression ring 61.

Embodiment 2

[0040] Such as Figure 1-3 As shown, this embodiment is based on Embodiment 1: the steel shed cave body 1 includes a column 11, a beam 12 and a longitudinal beam 13, and the beam 12 and the longitudinal beam 13 are connected to each other to form a roof frame 14 and a floor frame 15, and the column 11 The top frame 14 and the bottom frame 15 are connected.

[0041] Further, the piston spring strut 3 can be rotated and fixed around the rotating support 2. A number of bolt holes 16 are reserved in the transverse direction on the crossbeam 12. The bolt holes 16 are used to install the auxiliary rod 17, and the top of the auxiliary rod 17 faces the side of the mountain. tilt.

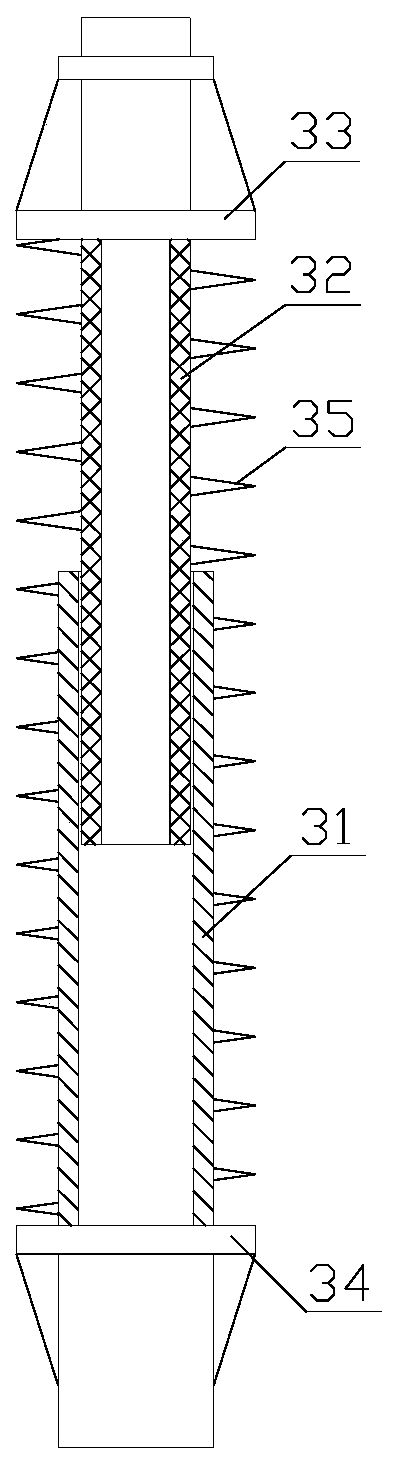

[0042] Further, the piston spring strut 3 includes a rod body 31 and a piston rod 32, the top of the rod body 31 is a hollow cylinder, the piston rod 32 is arranged inside the hollow cylinder, the top of the piston rod 32 is connected with the pulley 4, and the piston rod 32 below the pulley 4 A first space...

Embodiment 3

[0045] Such as Figure 1-3 As shown, this embodiment is based on Embodiment 2: the bottom of the column 11 or the side of the beam 12 is provided with a second rotating support 8, the second rotating support 8 is connected to a second piston spring strut 81, and the second piston The end of the spring strut 81 is connected to the second pulley 82, and the side of the column 11 is provided with a second protective net 9. The upper side of the second protective net 9 is connected to the top surface of the column 11, and the lower side is connected to the traction rope 91. The traction rope 91 After bypassing the second pulley 82, it is anchored on the side of the side slope 7 close to the bottom frame 15, and the side of the traction rope 91 close to the side slope 7 is provided with a second decompression ring 92.

[0046] Further, the structure of the second piston spring strut 81 is the same as that of the piston spring strut 3, and a number of bolt holes 16 are vertically re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com