Flue gas passage system capable of achieving adjacent furnace low-load denitration and mutual standby of flue gas channels

A flue gas passage, low-load technology, applied in combustion equipment, valve configuration, exhaust gas devices, etc., can solve the problems of unreachable denitration temperature and high transformation cost, achieve simple structure, low cost, and overcome the effect of standby equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

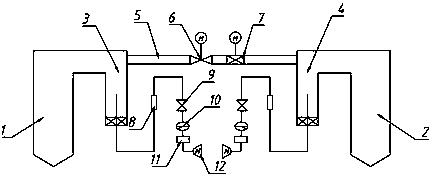

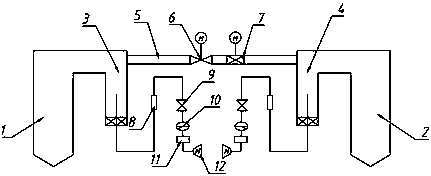

[0017] The present invention is a flue gas passage system that satisfies the low-load denitrification of adjacent furnaces and that the flue is a backup for each other, including two adjacent single-auxiliary boilers, namely the first single-auxiliary boiler 1 and the second single-auxiliary boiler 2, The first single-auxiliary boiler 1 is connected with a first flue gas passage 3, and the second single auxiliary boiler 2 is connected with a second flue gas passage 4, and the first flue gas passage 3 communicates with the flue gas passage 5. The second flue gas passage 4 is connected, and the flue gas flow regulating device is arranged on the flue gas passage 5 .

[0018] One end of the smoke passage 5 is connected to the tail of the first smoke passage 3 , and the other end of the smoke passage 5 is connected to the tail of the second smoke passage 4 .

[0019] The flue gas flow regulating device includes opening or closing the flue gas electric door 6 between the first flue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com