Water cup with liquid crystal temperature card and manufacturing method thereof

A temperature card and liquid crystal technology, applied in thermometers, thermometers with physical/chemical changes, drinking utensils, etc., can solve the problems of high price, troublesome manufacturing, high cost, etc., and achieve the effect of cheap price and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

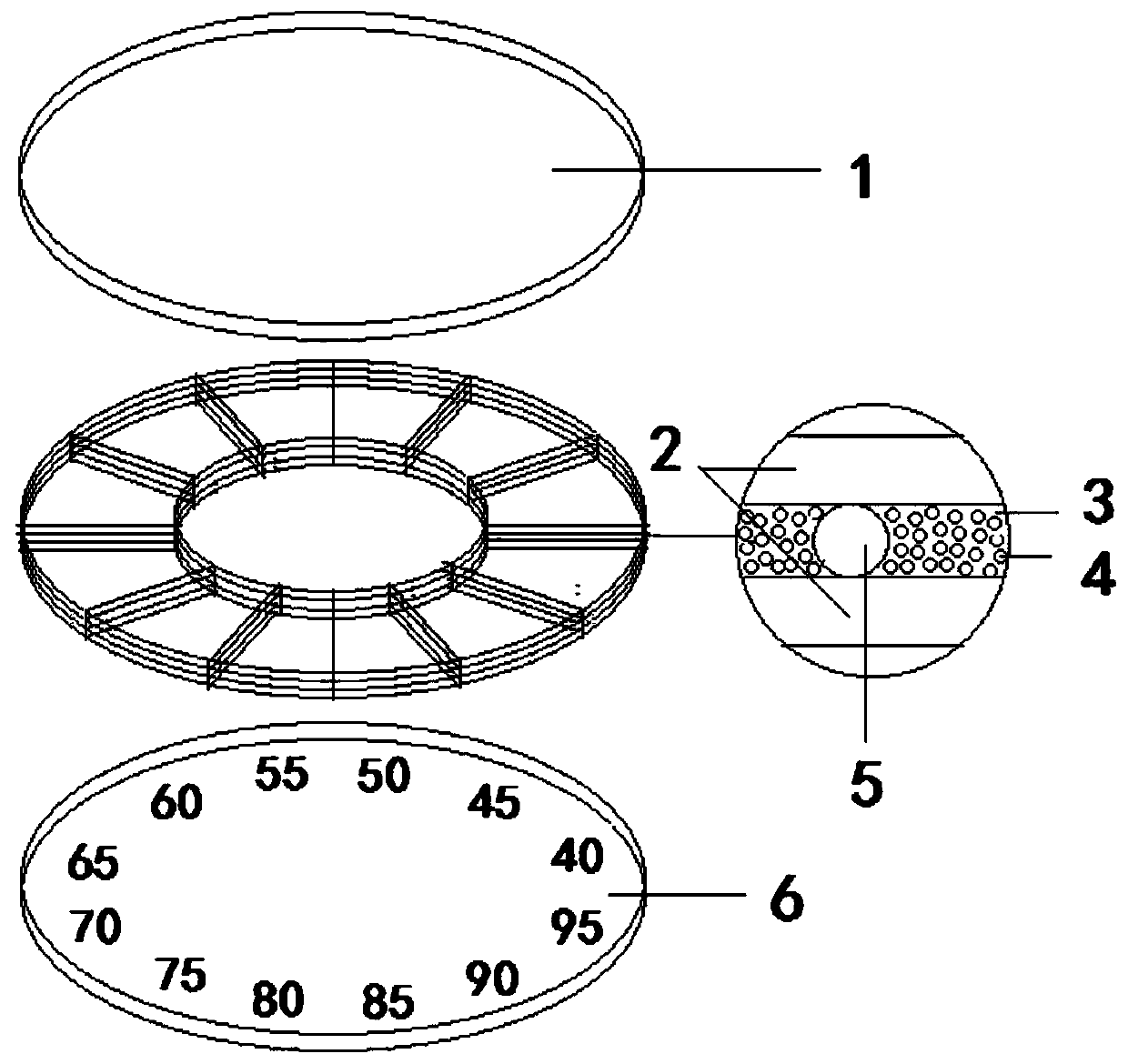

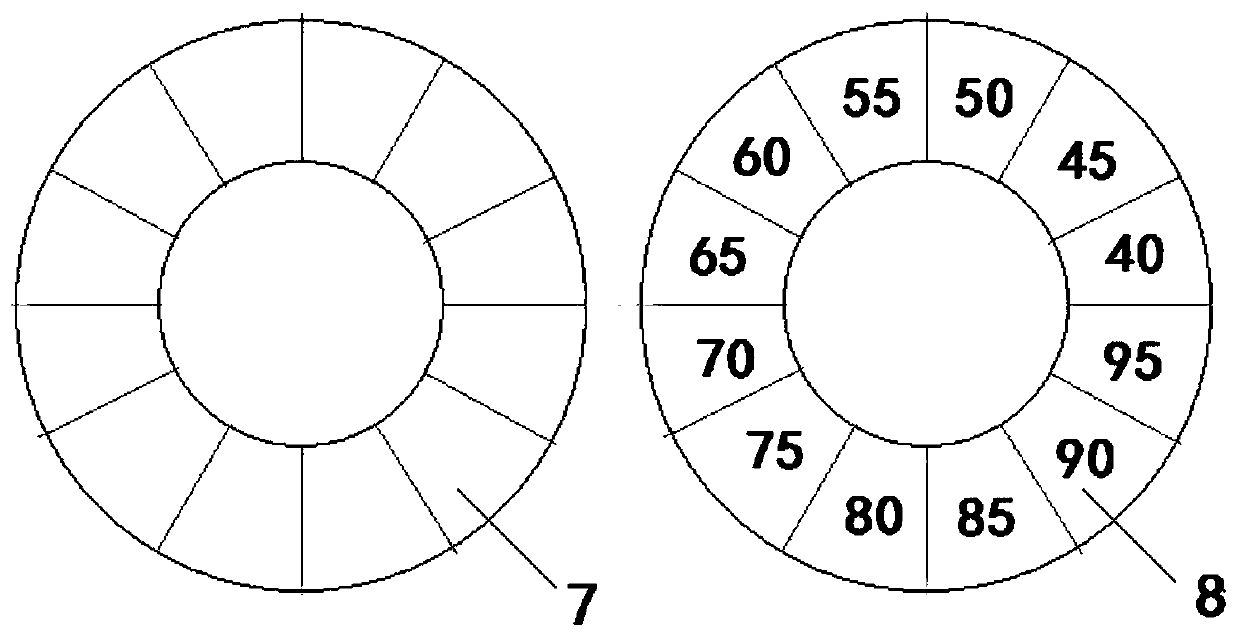

[0039] An embodiment of the bottom of a double-layer glass thermos cup with a liquid crystal temperature card. The temperature card is composed of two 0.5mm thick PC transparent thick films sandwiched by two 0.19mm thick PET transparent conductive films sandwiched by 0.125mm thick Polymer-dispersed liquid crystal layer, polymer-dispersed liquid crystal heat-sensitive dimming films arranged in sequence form a disk shape (diameter of the disk is about 4cm, thickness is about 1.5mm); the multiple sheets of polymer-dispersed liquid crystal thermally arranged in sequence The liquid crystals in the light-sensitive dimming film have different clearing point temperatures, arranged end to end according to the value of the clearing point temperature, and the films with different clearing point temperatures have different light colors, such as figure 1 Among them, the colors of adjacent polymer-dispersed liquid crystal thermosensitive dimming film films are different, the colors of the fo...

Embodiment 2

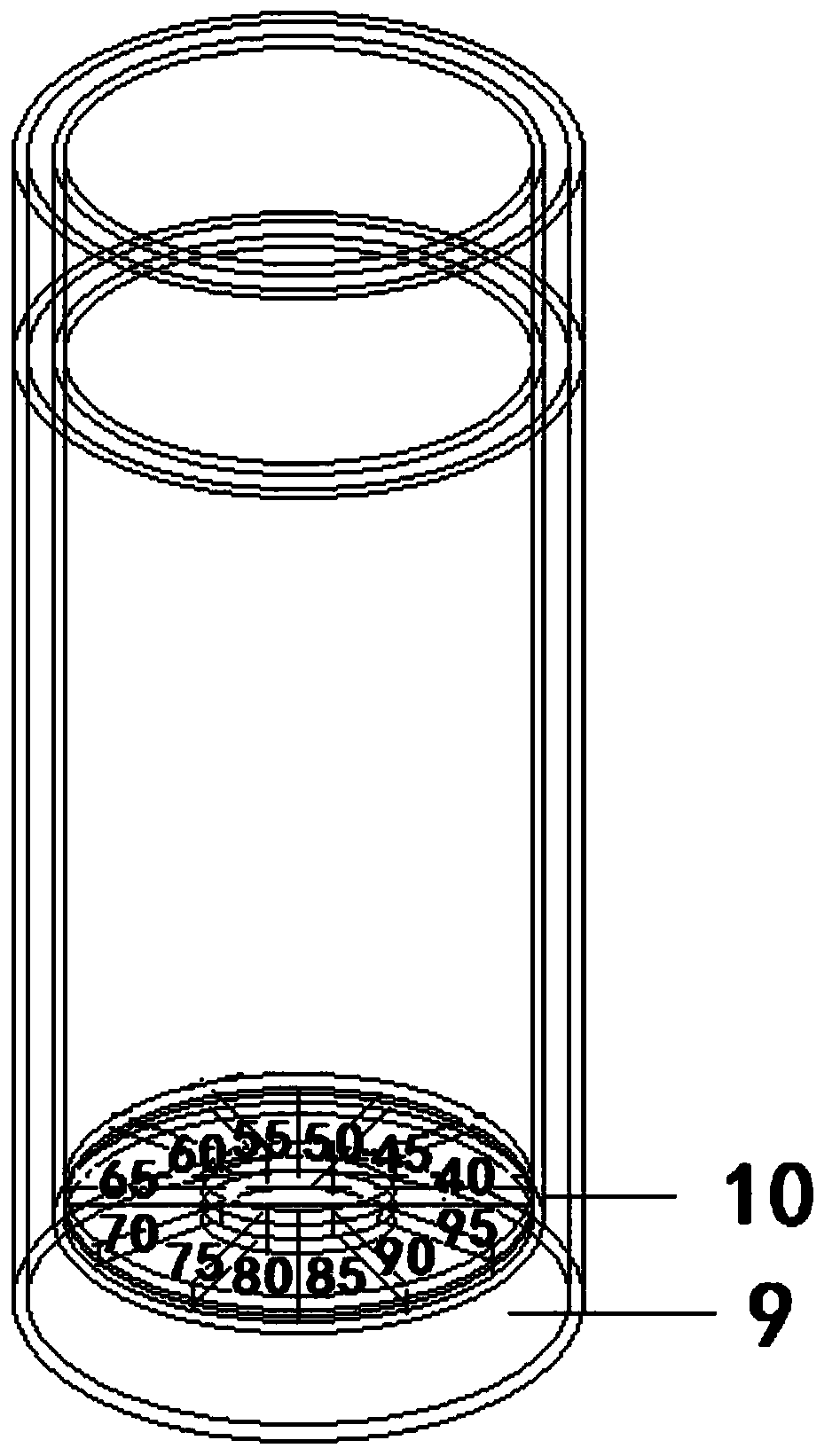

[0047] An embodiment of the transparent glass insulation cup wall of a water cup with a liquid crystal temperature card. The temperature card is composed of two 0.1mm thin PET transparent films sandwiching two 0.12mm thick PET transparent conductive thin films sandwiching a 0.125mm thick polymer Dispersed liquid crystal layer, polymer-dispersed liquid crystal film sheets arranged in sequence form a ring shape (the diameter of the ring is about 5.5cm, the width is about 1cm, the circumference is about 18cm, and the thickness is about 0.6mm); The liquid crystals in the material-dispersed liquid crystal film have different clearing point temperatures, and the colors are different according to the clearing point temperature, and they are arranged according to the value of the clearing point temperature.

[0048] Processes such as glue compounding and UV curing phase separation are the same as those in Example 1.

[0049] Cut the heat-sensitive dimming film into small rectangular p...

Embodiment 3

[0053]An embodiment of a stainless steel thermos cup with a liquid crystal temperature card. The temperature card is composed of two 0.5mm thick PC transparent films sandwiched by two 0.19mm thick PET transparent conductive films sandwiched by 0.125mm thick The polymer-dispersed liquid crystal film sheet forms a disk shape (the diameter of the disk is about 4cm, and the thickness is 1.5mm); the liquid crystals in the multiple polymer-dispersed liquid crystal film sheets arranged in sequence have different clearing point temperatures, and have different Colors are arranged according to the magnitude of the clearing point temperature value.

[0054] The polymer-dispersed liquid crystal film includes liquid crystal and an ultraviolet curable polymer with an average refractive index close to that of the liquid crystal and doped with a small amount of spacers. The clearing point temperatures of the liquid crystals in two adjacent polymer-dispersed liquid crystal film sheets differ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com