Quick response type fiber bragg grating humidity sensor system and application method thereof

A technology of humidity sensor and fiber optic Bragg, which is applied in the field of fiber Bragg grating humidity sensor system, can solve the problems of limited degree, reduce the humidity sensitivity of FBG humidity sensor, reduce the thickness of humidity sensitive film, etc., so as to improve the response speed and facilitate large-scale assembly net effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

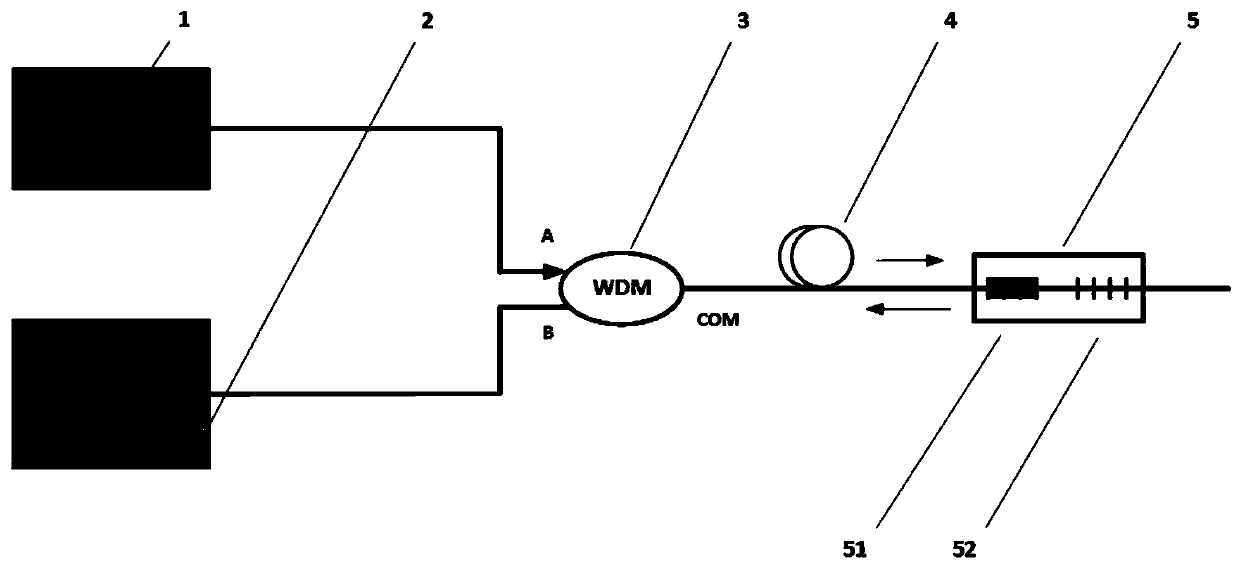

[0031] A fast-response fiber Bragg grating humidity sensor system, including sequentially connected light source 1, wavelength division multiplexer 3, transmission optical fiber 4, FBG humidity sensor 5, and demodulation equipment connected to the wavelength division multiplexer 3 2. The light source 1 is a 1480nm Raman pump light source and the wavelength of the output light is staggered from the output wavelength of the light source in the demodulation device 2. The light source 1 and the demodulation device 2 are respectively connected to the wavelength division multiplexer 3 according to their respective output light bands On the two different wavelength channels, the common end of the wavelength division multiplexer 3 is connected to the FBG humidity sensor 5 through a section of transmission fiber 4, and the FBG humidity sensor 5 is structured to engrave two FBGs next to each other on the optical fiber as the temperature FBG and the temperature FBG respectively. Humidity ...

Embodiment 2

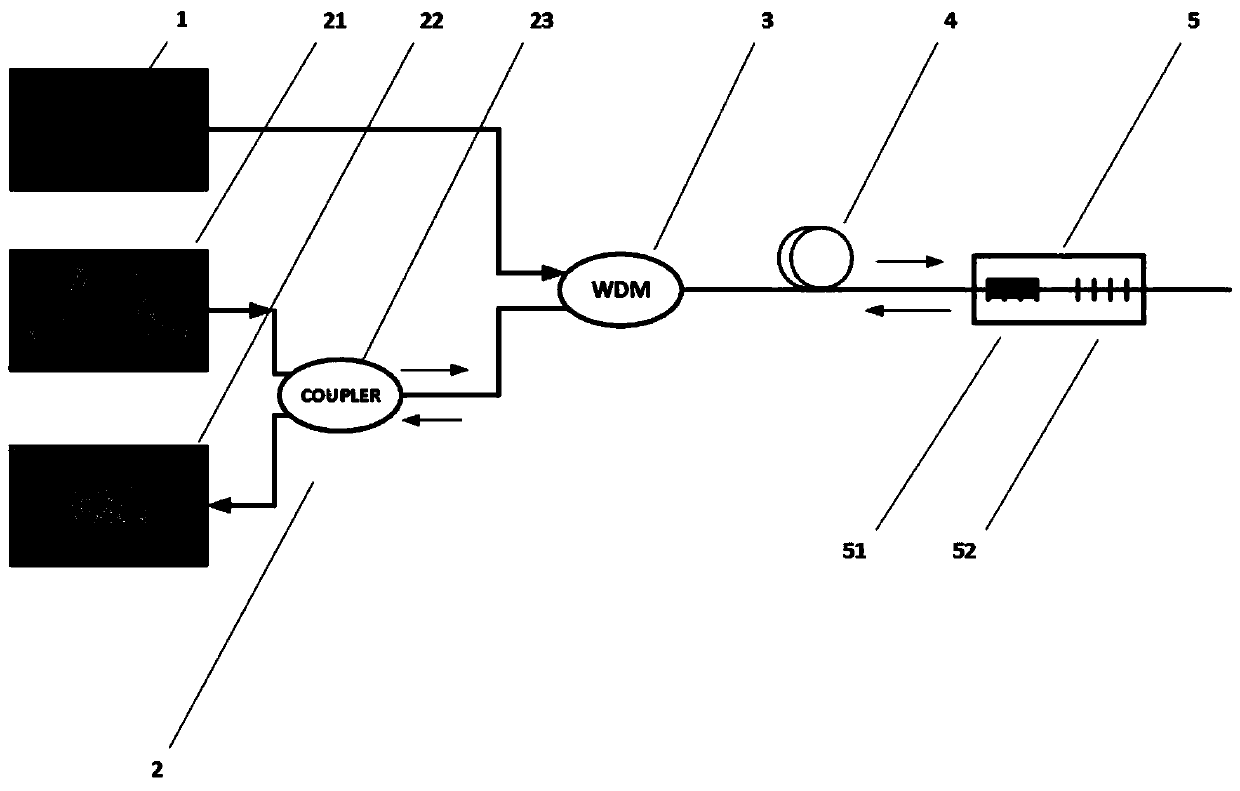

[0039] On the basis of Example 1, the light source 1 is replaced by a 980nm pumping light source. The humidity sensitive film is made of PMMA polymethyl methacrylate material. The demodulation device 2 is replaced by an FBG wavelength demodulation system composed of an ASE light source, a fiber coupler, and a spectrum analyzer. The transmission fiber 4 is a long-distance transmission fiber with a length of 10 km. The wavelength division multiplexer 3 is a 980nm / 1550nm wavelength division multiplexer.

[0040] According to the actual experimental application test, compared with the solution in Example 1, it can achieve similar measurement and use effects, and can meet the requirements of real-time humidity measurement in harsh environments such as flammable, explosive, and strong electromagnetic interference.

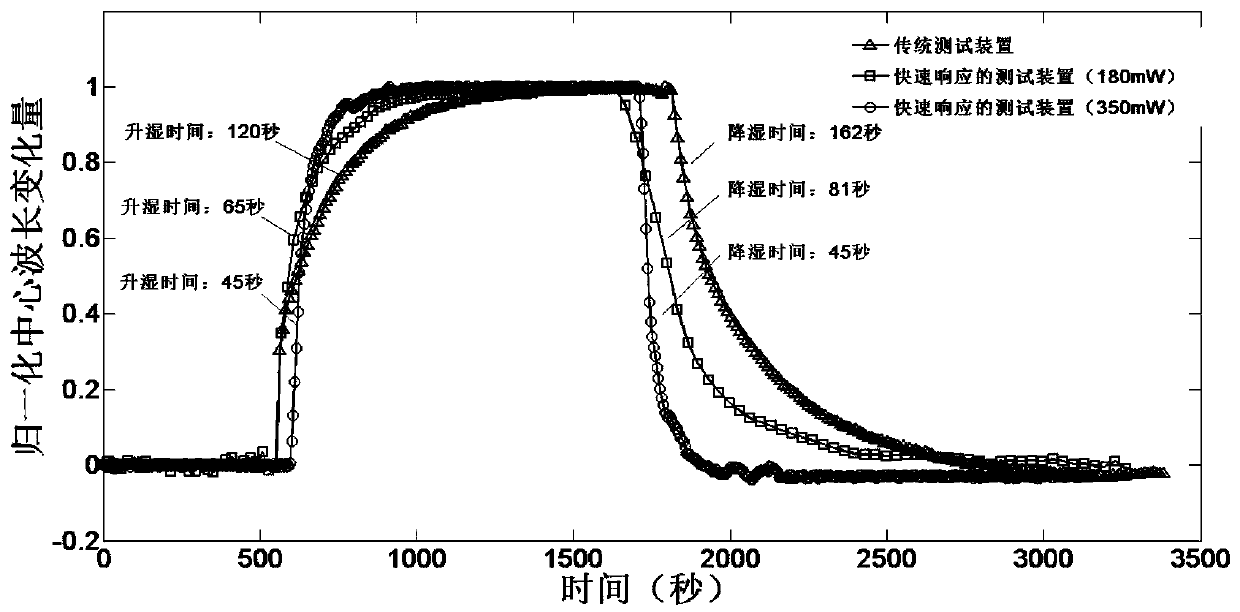

[0041] The above experiments show that the fast-response FBG humidity sensor system provided by the present invention can greatly improve the response speed of the exi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com