Optimization device for expanding automatic screening and testing contact surface of chip

A technology for automatic screening and optimization of devices, applied in semiconductor/solid-state device testing/measurement, electrical components, semiconductor/solid-state device manufacturing, etc. Insufficient contact, etc., to avoid secondary testing, increase contact area, and improve yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the drawings and embodiments.

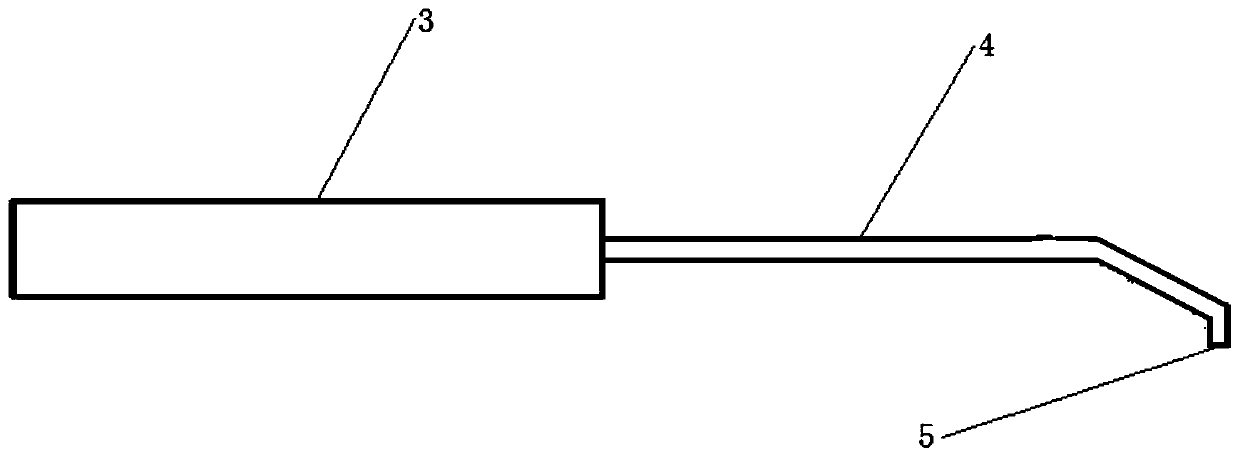

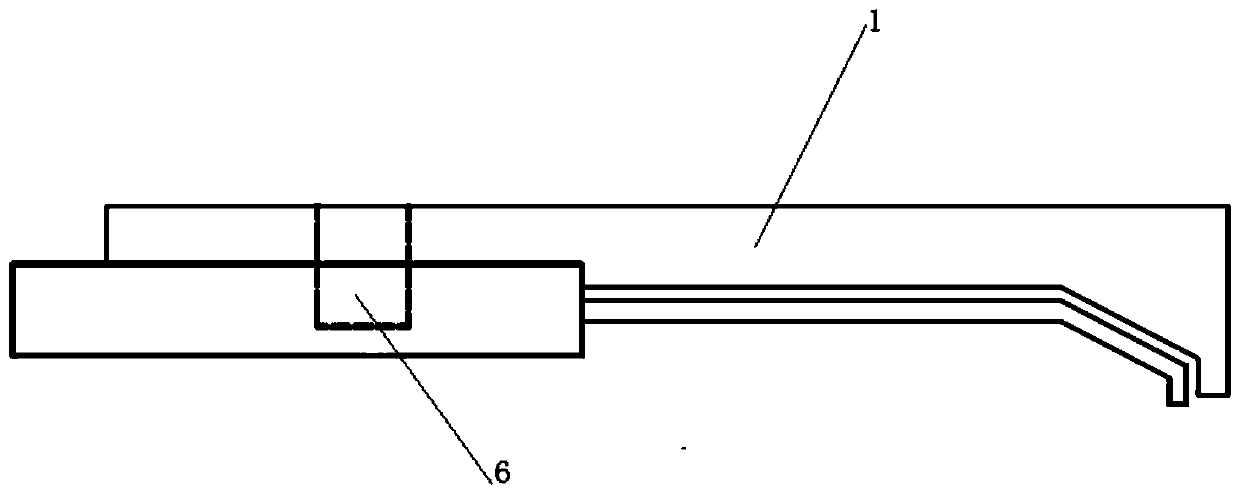

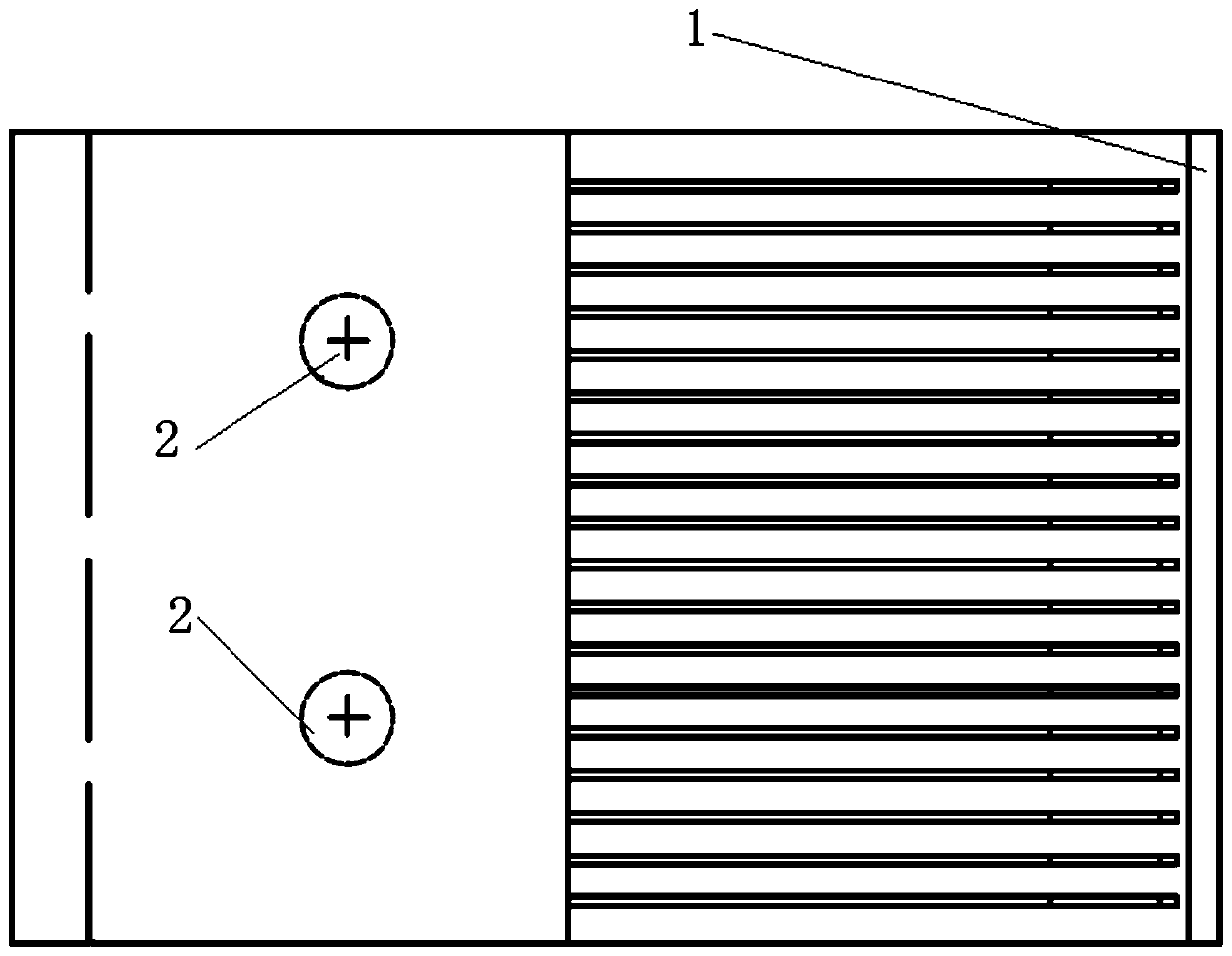

[0020] An optimization device for expanding the chip's automatic screening and testing contact surface, including an insulating baffle 1, which is arranged on the back of the gold finger fixing device 3 and the gold finger 4, and the gold finger 4 is fixed on the gold finger On device 3. The insulating baffle 1 is attached to the shape of the back of the alloy finger 4 to prevent deformation of the gold finger. Screw holes 6 are arranged on the insulating baffle 1 and the golden finger 4 fixing device, and screws 2 are arranged in the screw holes 6.

[0021] Some parts of Golden Finger 4 are modified to meet certain IC chip tests that have strict requirements on contact impedance. Only by modifying the 4 parts of the golden finger, the test yield of the gravity manipulator can be increased to more than 95%, which greatly improves the factory performance, and the modifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com