Shock-absorbing sole and shock-absorbing shoe

A technology for shock-absorbing shoes and uppers, which is applied to soles, footwear, applications, etc., and can solve problems such as poor shock-absorbing effects and weakened vibrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[2042] In the preparation process of the dilatant component, other optional additives are preferably antioxidants, heat stabilizers, crosslinking agents, toughening agents, compatibilizers, phase change additives, plasticizers, and foaming agents.

[2043] In the present invention, the optional fillers mainly play the following roles in the shoe material: ① reduce the shrinkage of the product, improve the dimensional stability, surface finish, smoothness and flatness or dullness of the product etc.; ②Adjust viscosity; ③Meet different performance requirements, such as improving the impact strength and compressive strength, hardness, stiffness and modulus of shoe materials, improving wear resistance, increasing heat distortion temperature, improving electrical conductivity and thermal conductivity, etc.; ④Improving pigment Excellent coloring effect; ⑤ endows light stability and chemical corrosion resistance; ⑥ acts as a compatibilizer, which can reduce costs and improve the compe...

Embodiment 1

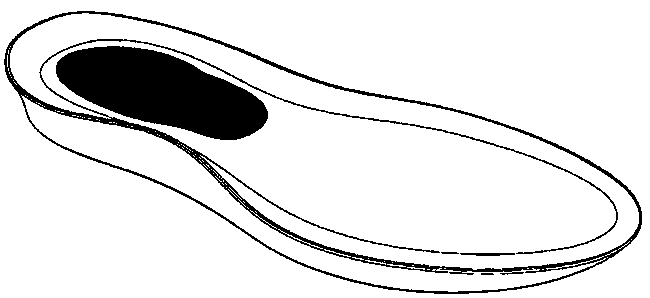

[2089] An insole of a shock-absorbing shoe, in which a dilatant component with a simple hollow structure is inlaid on the part from the forefoot to the heel of the insole, which uses dynamic dilatant polyurethane as a matrix, and is pasted on the outside of the dilatant component There is a ring of force-responsive component material (as attached figure 2 shown), wherein the force-responsive component and the dilatant component are prepared by the following method:

[2090]

[2091] Add 10g ethylenediamine polyether tetraol, 1.2g cyclopentadiene compound (a), 3.8g dicyclohexylcarbodiimide condensing agent, 0.5g catalyst 4-dimethylaminopyridine in a dry and clean reaction flask and mix Evenly, react for 6 hours under reflux conditions, then add 3.1g diketene compound (b), stir and mix evenly, continue to react for 6 hours, fill it into a mold with a certain shape, and keep it warm at 60°C for 6 hours to obtain force Responsive components.

[2092] Weigh 20g of hydroxyl-te...

Embodiment 2

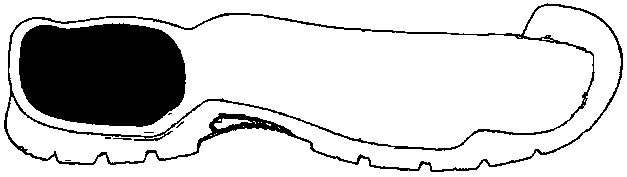

[2095] A shock-absorbing shoe (sole), which uses a granular dilatant component with a simple hollow structure to make an integrated body of a midsole and a shoe outsole, and the dilatant component uses dynamic dilatant polyurethane as a matrix, and block-shaped force-responsive components are inlaid on the periphery of the integrated body, wherein the force-responsive components and dilatant component particles are prepared by the following method:

[2096]

[2097] Using equimolar amounts of 2-aminomethylbenzeneboronic acid and 2-(4-aminobutyl)propane-1,3-diol as raw materials and tetrahydrofuran as a solvent, carry out condensation reaction at 60°C to obtain borate ester compound (c).

[2098] In a dry and clean flask, take by weighing 200ml chloroform, polyoxypropylene triol, 1.5g carboxylic acid compound (a) of 10g, 0.8g 1,6-dipic acid, 3.8g dicyclohexylcarbodiimide condensing agent, Mix 0.5g catalyst 4-dimethylaminopyridine evenly, react at 80°C for 6h, then add 2.20g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact | aaaaa | aaaaa |

| Impact | aaaaa | aaaaa |

| Impact | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com