Reaction device and system and method for synthesizing acetic acid through methanol carbonylation

A reaction device, acetic acid technology, applied in carbon monoxide reaction to prepare carboxylic acid, chemical instrument and method, feeding device, etc., can solve the problems of production capacity decline, easy damage of shaft seal and bearing, difficulty in stable and safe operation, etc. Achieve the effect of increasing production capacity, avoiding easy damage, and eliminating hidden dangers of parking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

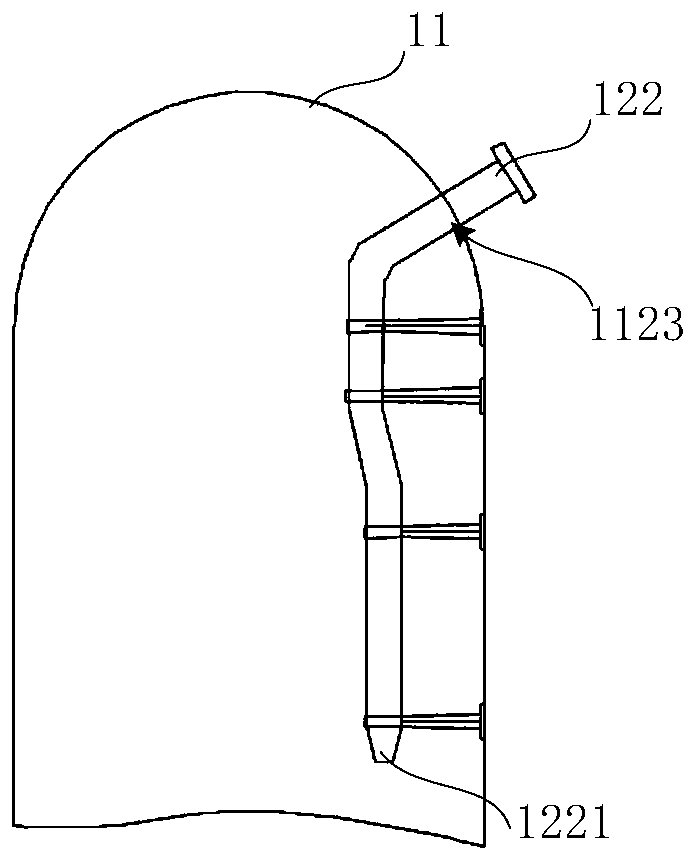

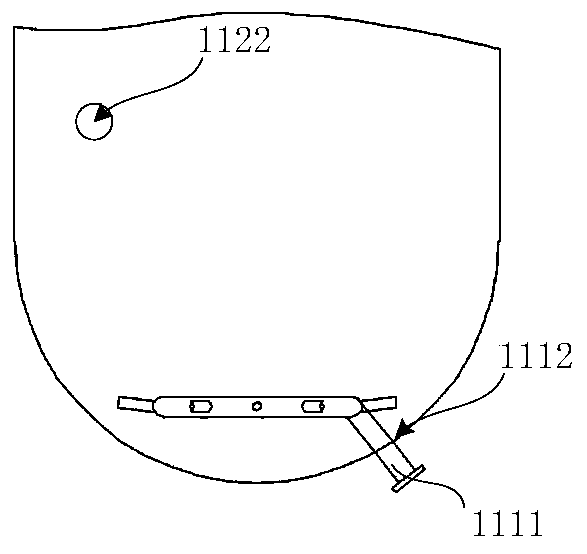

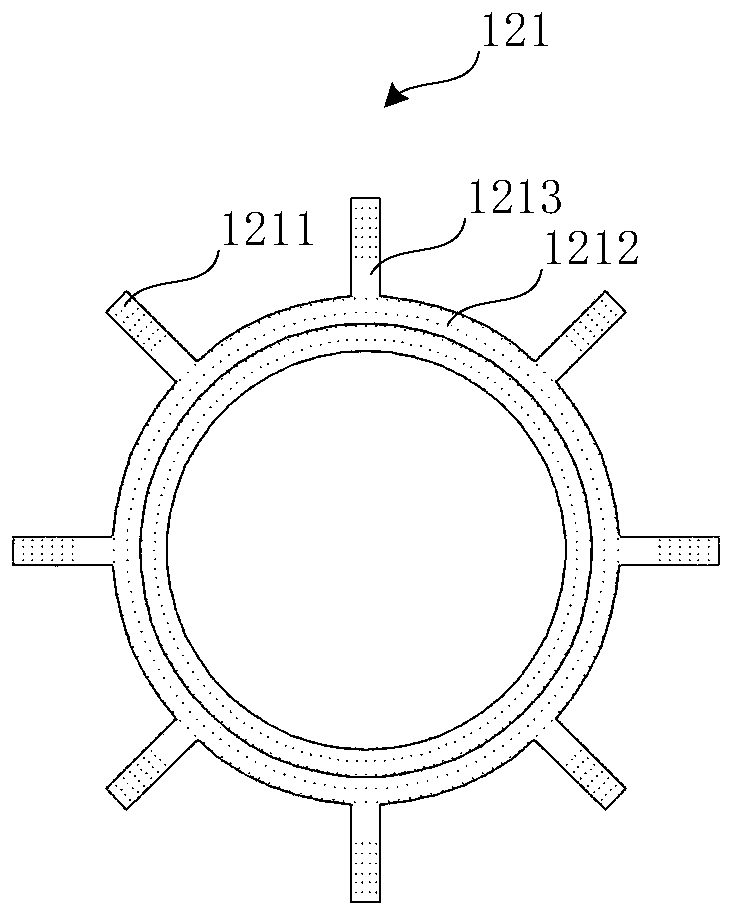

[0077] Methanol carbonylation acetic acid industrial device, after reforming the reactor, adopt the present invention figure 1 and figure 2 Fluid stirring components shown and image 3 In the shown reaction raw material distributor (annular first distribution unit and 5 second distribution units, the annular array of 5 second distribution units is arranged on the annular first distribution unit), the nozzle 1221 is located below the liquid level of the reaction device, The distance between the spray head 1221 and the return inlet 1123 is 1 / 3 of the height of the reactor cylinder. Under the conditions of certain temperature and pressure and the presence of catalyst, methanol and CO undergo carbonylation reaction to generate acetic acid, and the outlet flow rate of the return circulation pump is 300m 3 / h (eg Figure 5 Shown), the production capacity is increased by 10% relative to the comparison ratio.

Embodiment 2

[0079] Methanol carbonylation acetic acid industrial device, after reforming the reactor, adopt the present invention figure 1 and figure 2 Fluid stirring components shown and image 3 In the shown reaction raw material distributor (annular first distribution unit and 8 second distribution units, the annular array of 8 second distribution units is arranged on the first annular distribution unit), the nozzle 1221 is located below the liquid level of the reaction device, The distance between the spray head 1221 and the return material inlet 1123 is 1 / 2 of the height of the reactor cylinder. Under the conditions of certain temperature and pressure and the presence of catalyst, methanol and CO undergo carbonylation reaction to generate acetic acid, and the outlet flow rate of the return circulation pump is 700m 3 / h, the relative production capacity is increased by 20%

Embodiment 3

[0081] Methanol carbonylation acetic acid industrial device, after reforming the reactor, adopt the present invention figure 1 and figure 2 Fluid stirring components shown and image 3 In the shown reaction raw material distributor (annular first distribution unit and four second distribution units, the annular array of four second distribution units is arranged on the first annular distribution unit), the nozzle 1221 is located below the liquid level of the reaction device, The distance between the spray head 1221 and the return material inlet 1123 is 1 / 5 of the cylinder height of the reactor. Under the conditions of certain temperature and pressure and the presence of catalyst, methanol and CO undergo carbonylation reaction to generate acetic acid, and the outlet flow rate of the return circulation pump is 530m 3 / h, the production capacity is increased by 15% relative to the comparison ratio.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com