Magnetic abrasive finishing trolley for finishing metal plane plate and method

A technology of magnetic grinding and flat plate, which is applied to machine tools, metal processing equipment, grinding machines and other directions suitable for grinding workpiece planes, and can solve problems such as the limitation of the size of processed workpieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below, but the implementation scope of the present invention is not limited to the following embodiments.

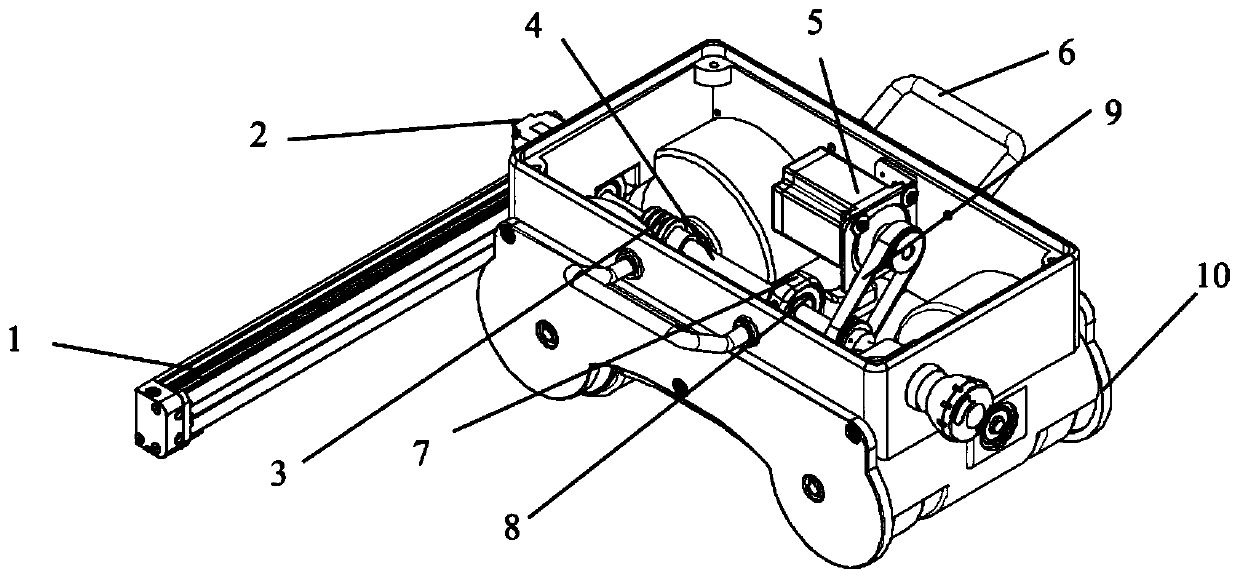

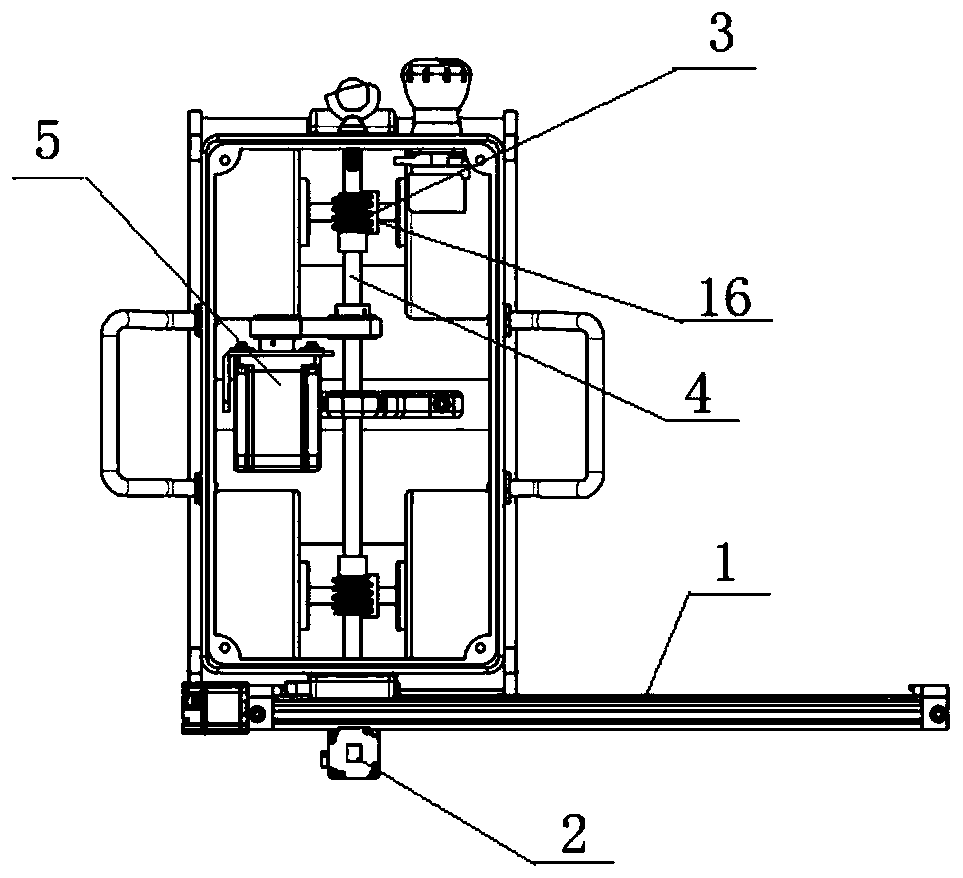

[0022] like Figure 1-Figure 5 As shown, a magnetic grinding trolley for smoothing metal flat plates includes a walking trolley, a screw guide rail 1, a magnetic grinding head, and a grinding motor 2. The screw guide rail 1 is installed on the end of the walking trolley, and the grinding motor 2 is fixed on the slider of the lead screw guide rail 1, and the grinding motor 2 drives the magnetic grinding head to rotate.

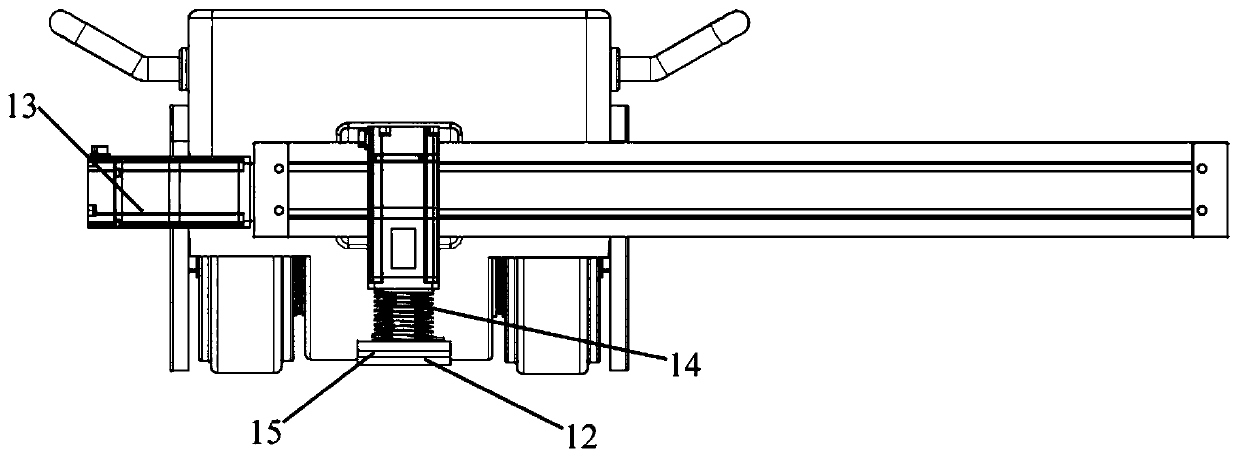

[0023] Described magnetic grinding head comprises collet 11, thrust bearing 15, axial magnetic pole 12, spring 14, is fixed with axle sleeve 18 on described axial magnetic pole 12, and thrust bearing 12 is installed on axial magnetic pole 12 and collet. 11, the bushing 18 extends into the collet 11 and is sleeved on the grinding motor shaft 19, the bushing 18 and the grinding motor shaft 19 are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com