Production process of plastic chain of mud scraper

A production process and mud scraper technology, applied in the direction of coating, etc., can solve problems such as elongation plastic deformation, chain plate fracture, etc., and achieve the effect of increasing tensile strength, improving tensile strength and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

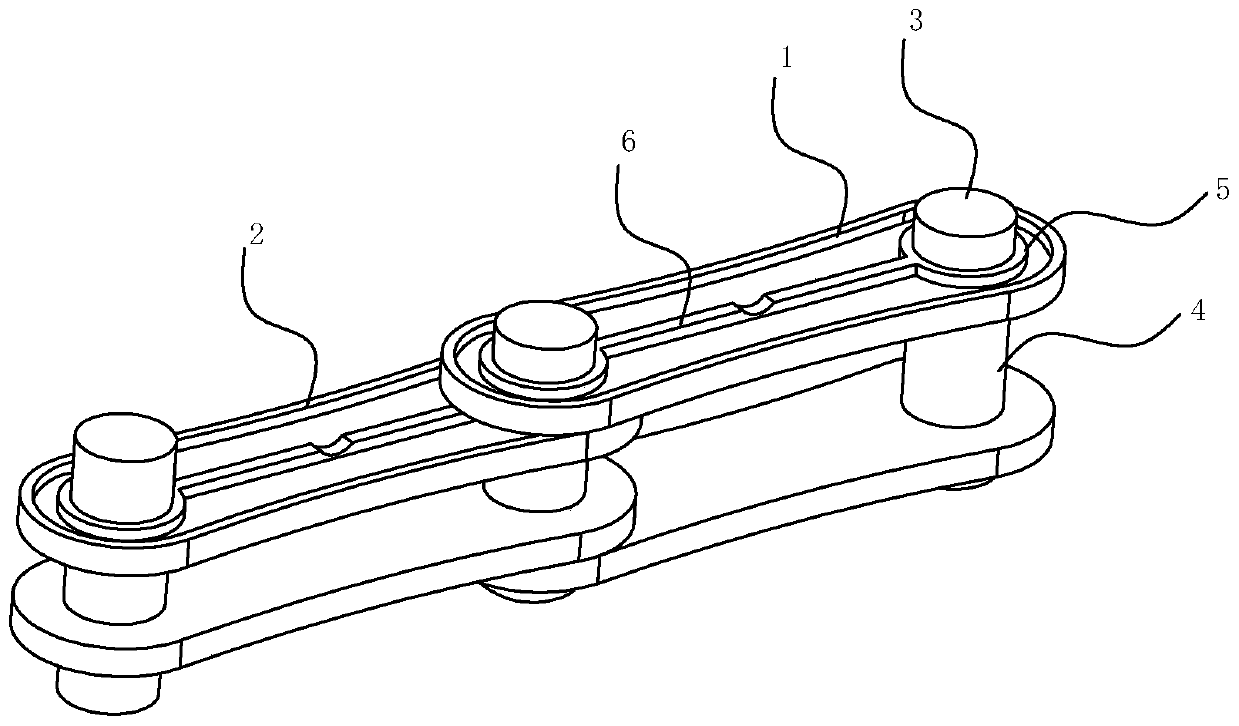

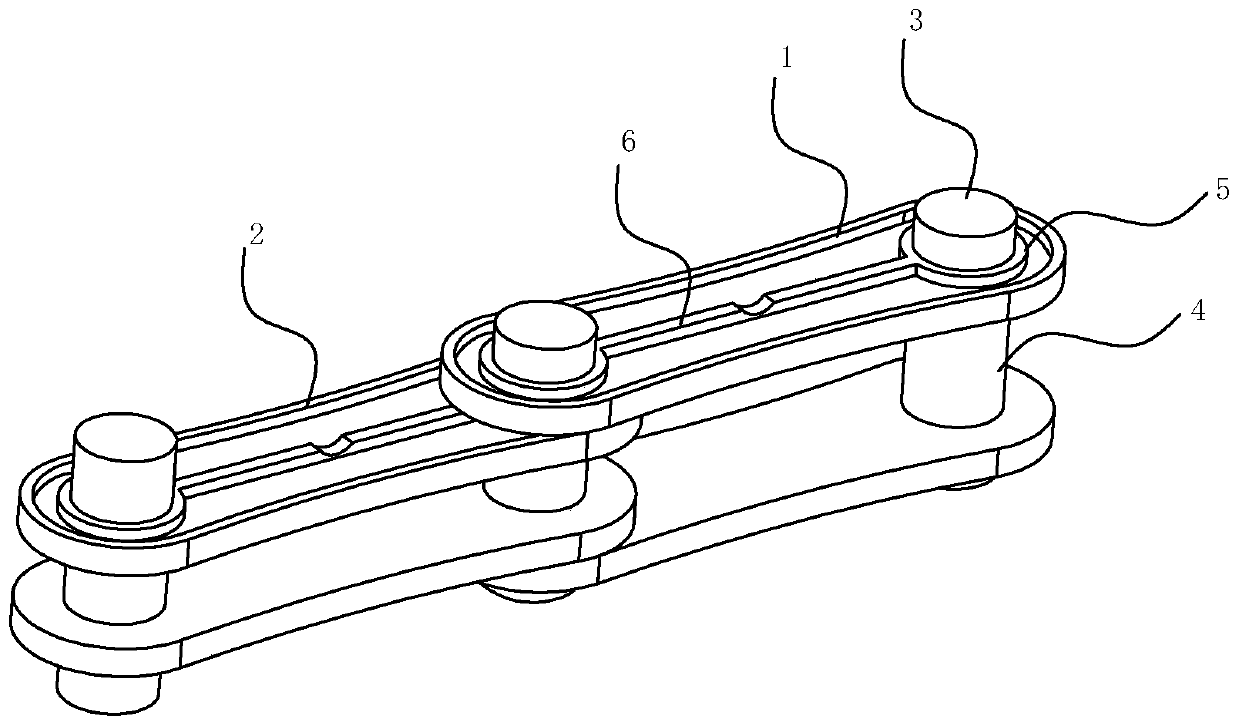

[0064] Example 1: A production process of a plastic chain for a mud scraper. The plastic chain is composed of a plurality of chain links connected in series. The structure and size of the chain plate 1 and the inner chain plate 2 are the same, the inner sides of the two inner chain plates 2 are integrally injection molded by the sleeve 4, and the two ends of the two outer chain plates 1 are attached to the two inner chain plates 2 respectively. On the outer sides of the two ends, the outer link plate 1 and the inner link plate 2 are connected through the pin shaft 3 inserted into the sleeve 4, the pin shaft 3 is rotated in the sleeve 4, and the circlip 5 is located at both ends of the pin shaft 3 and snapped into the sleeve 4.

[0065] The outer surface of the outer link plate 1 is integrally injection-molded with reinforcing ribs 6 along its length direction, and the position where the reinforcing ribs 6 contact with the outer link plate 1 is set in a hollow shape, so as to g...

Embodiment 2

[0101] Embodiment 2: A production process of plastic chains for mud scrapers. The difference from Embodiment 1 is that in this embodiment, the outer chain plate 1 is composed of the following components by weight:

[0102] POM: 90 parts;

[0103] Polybutadiene epoxy resin: 60 parts;

[0104] Polyamide: 30 parts;

[0105] Glass fiber: 45 parts;

[0106] Glycerin: 2.5 parts;

[0107] Tert-butyl hydroquinone: 3 parts;

[0108] Talcum powder: 10 parts;

[0109] Carbon black: 3 parts;

[0110] Polyimide: 2.5 parts.

Embodiment 3

[0111] Embodiment 3: A production process of a plastic chain for a mud scraper. The difference from Embodiment 1 is that in this embodiment, the outer chain plate 1 is composed of the following components by weight:

[0112] POM: 100 parts;

[0113] Polybutadiene epoxy resin: 80 parts;

[0114] Polyamide: 35 parts;

[0115] Glass fiber: 50 parts;

[0116] Glycerin: 3 parts;

[0117] Tert-butyl hydroquinone: 4 parts;

[0119] Carbon black: 4 parts;

[0120] Polyimide: 3 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| fatigue strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com