PDMS/SiC functional gradient substrate and preparation method and application thereof

A functional gradient and substrate technology, applied in semiconductor/solid-state device manufacturing, manufacturing tools, additive manufacturing, etc., can solve the problem of damage to connected circuits and embedded electronic components, difficulty in the normal operation of flexible electronic products, and restrictions on the performance and function of flexible electronics, etc. problem, to achieve the effect of reducing processing steps, ensuring performance, and small thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

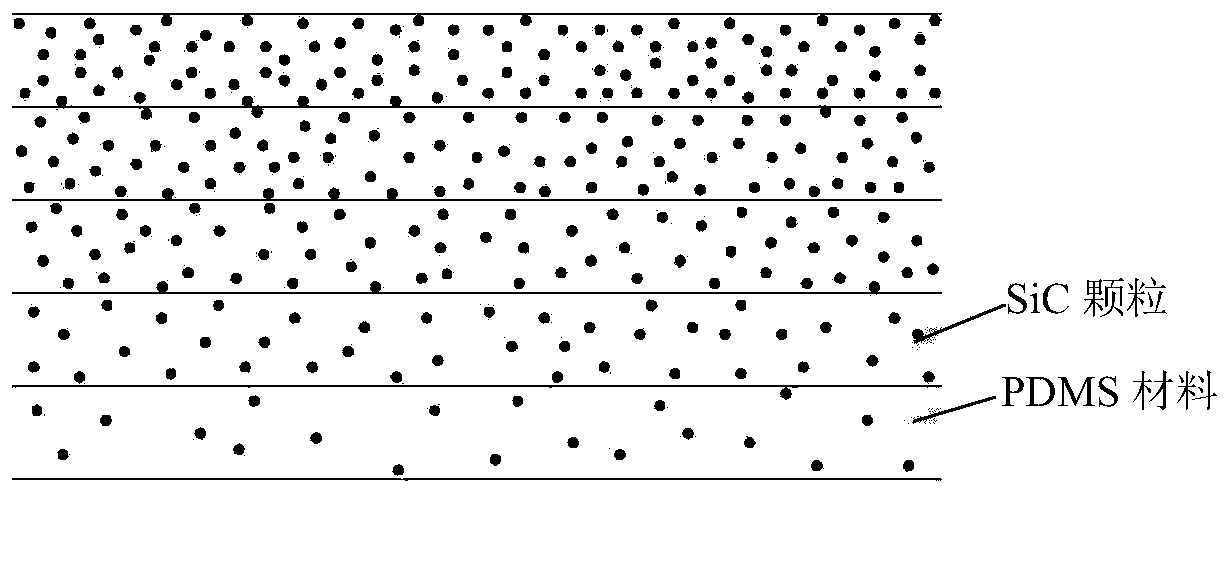

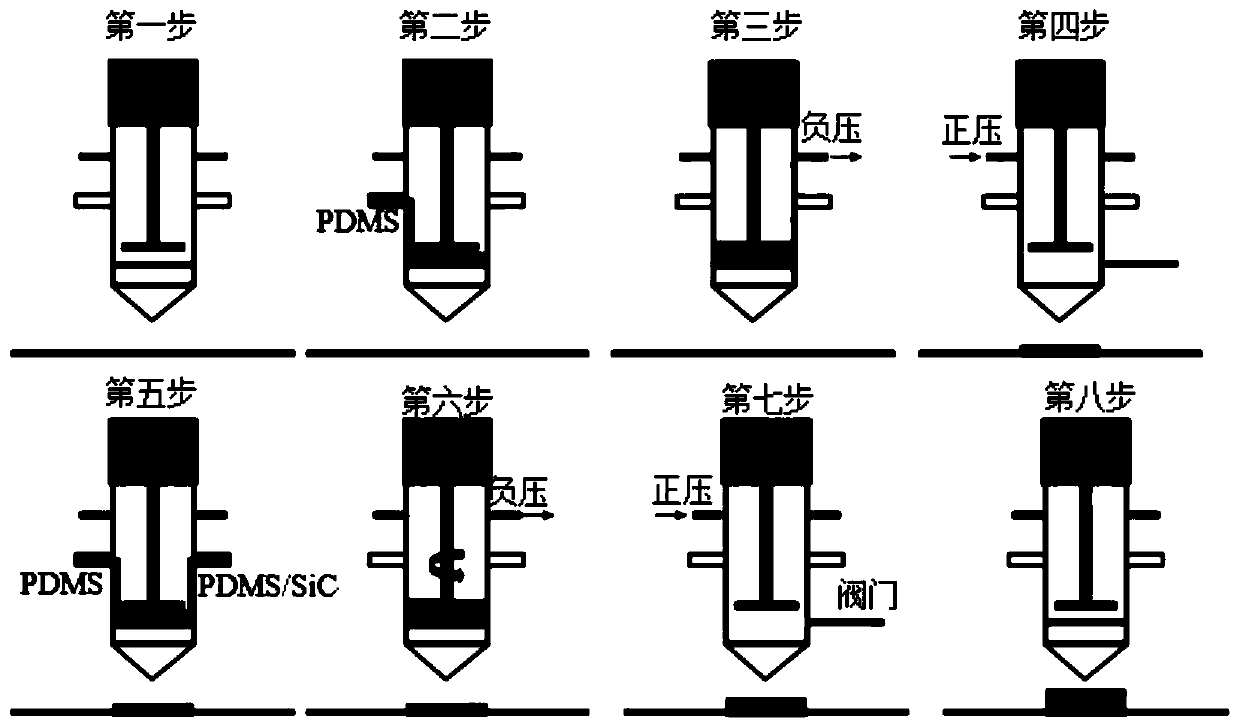

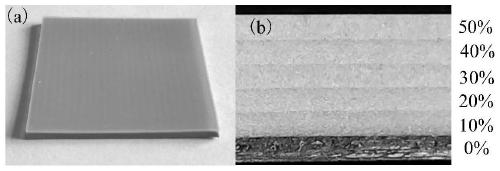

[0048] Such as figure 2 As shown, the specific method of PDMS / SiC functionally graded substrate:

[0049] Step 1: Printing material I and printing material II pretreatment. After uniformly mixing PDMS and curing agent at a ratio of 10:1 and vacuuming to remove air bubbles, it is used as the raw material of the feeding module I (printing material I). First, pure PDMS is prepared according to the ratio of PDMS and curing agent 10:1, and then the PDMS-SiC-curing agent mixture (printing material II) is prepared according to the silicon content of 50%. During the preparation process, the PDMS-SiC - Mix the curing agent mixture evenly.

[0050] Step 2: Pre-printing processing. Put the configured printing material I into the feeding device I, and put the processed printing material II into the feeding device II; the printing platform is heated to 80°C; the printing nozzle and the printing platform move to the initial printing position (i.e. print origin), complete the preparatio...

Embodiment 2

[0060] Such as figure 2 As shown, the specific method of PDMS / SiC functionally graded substrate:

[0061] Step 1: Printing material I and printing material II pretreatment. After uniformly mixing PDMS and curing agent according to 9:1 and vacuuming, it is used as the raw material of feeding module I (printing material I). First, pure PDMS is prepared according to the ratio of PDMS and curing agent 10:1, and then the PDMS-SiC-curing agent mixture (printing material II) is prepared according to the silicon content of 40%. During the preparation process, the PDMS-SiC - Mix the curing agent mixture evenly.

[0062] Step 2: Pre-printing processing. Put the configured printing material I into the feeding device I, and put the processed printing material II into the feeding device II; the printing platform is heated to 80°C; the printing nozzle and the printing platform move to the initial printing position (i.e. print origin), complete the preparations.

[0063] Step 3: Print....

Embodiment 3

[0069] Such as figure 2 As shown, the specific method of PDMS / SiC functionally graded substrate:

[0070] Step 1: Printing material I and printing material II pretreatment. After uniformly mixing PDMS and curing agent according to 10:1 and evacuating, it is used as the raw material of feeding module I (printing material I). First, pure PDMS is prepared according to the ratio of PDMS and curing agent 10:1, and then the PDMS-SiC-curing agent mixture (printing material II) is prepared according to the silicon content of 30%. During the preparation process, the PDMS-SiC - Mix the curing agent mixture evenly.

[0071] Step 2: Pre-printing processing. Put the configured printing material I into the feeding device I, and put the processed printing material II into the feeding device II; the printing platform is heated to 75°C; the printing nozzle and the printing platform move to the initial printing position (i.e. print origin), complete the preparations.

[0072] Step 3: Prin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com