Degradable high-strength stretch film and preparation method thereof

A high-strength, stretch film technology, used in chemical instruments and methods, flat products, other household appliances, etc., can solve the problems of large amount of stretch film, waste and other problems, achieve reasonable ratio, reduce production costs, heat sealing high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

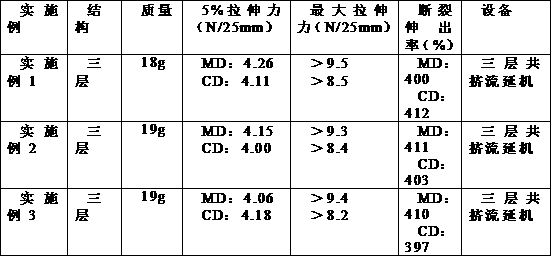

Embodiment 1

[0014] The degradable high-strength stretch film components (by weight) include:

[0015] The first layer: 5 parts of LLDPE and MDPE, 0.8 part of PHBV, 0.2 part of silicone oil;

[0016] The second layer: 5 parts of LLDPE and LDPE, 0.8 part of PHBV, 0.2 part of silicone oil;

[0017] The third layer: 5 parts of LLDPE and MDPE, 0.8 part of PHBV, 0.2 part of silicone oil;

[0018] Preparation: adopt one-step co-extrusion casting molding, weigh LDPE, MDPE, LLDPE raw material particles and auxiliary materials according to the requirements of different weight ratios for each layer, mix them evenly, and dry at 150°C for 2 hours; after heating at 280°C, extruding Pressing, casting, and then cooling at 20°C with chilled rolls.

Embodiment 2

[0020] The degradable high-strength stretch film components (by weight) include:

[0021] The first layer: 8 parts of LLDPE and MDPE, 0.7 part of PHBV, 0.3 part of silicone oil;

[0022] The second layer: 3 parts of LLDPE and LDPE, 0.7 part of PHBV, 0.1 part of silicone oil;

[0023] The third layer: 4 parts of LLDPE and MDPE, 0.8 part of PHBV, 0.2 part of silicone oil;

[0024] Preparation: adopt one-step co-extrusion casting molding, weigh LDPE, MDPE, LLDPE raw material particles and auxiliary materials according to the requirements of different weight ratios for each layer, mix them evenly, and dry them at 150°C for 2 hours; after heating at 250°C, extruding Pressing, casting, and then cooling at 25°C with chilled rolls.

Embodiment 3

[0026] The degradable high-strength stretch film components (by weight) include:

[0027] The first layer: 6 parts of LLDPE and MDPE, 0.8 part of PHBV, 0.3 part of silicone oil;

[0028] The second layer: 5 parts of LLDPE and LDPE, 0.9 part of PHBV, 0.1 part of silicone oil;

[0029] The third layer: 6 parts of LLDPE and MDPE, 0.9 part of PHBV, 0.1 part of silicone oil;

[0030] Preparation: adopt one-step co-extrusion casting molding, weigh LDPE, MDPE, LLDPE raw material particles and auxiliary materials according to the requirements of different weight ratios for each layer, mix them evenly, and dry at 150°C for 2 hours; after heating at 270°C, extruding It is formed by pressing, casting, and cooling at 30°C by a chill roll.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com