Novel two-dimensional heterojunction material and preparation method thereof

A two-dimensional heterojunction and heterojunction technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, vanadium compounds, etc., can solve the problem of low concentration, inability to precisely control the concentration of metal atoms, and time-consuming And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

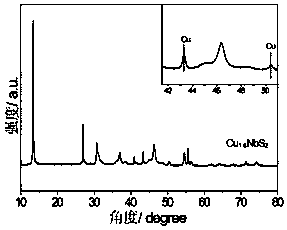

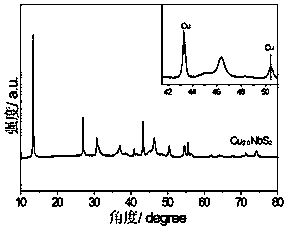

[0051] Preparation of 2D Cu x Nb 2 (0

[0052] Step 1): take by weighing 0.67g metal Nb powder (purity ≥ 99.99%, particle diameter 325 orders) and 0.48g sublimated sulfur, in the glove box (H 2 O2 2 compound.

[0053] Step 2): Weigh 100.0mg NbS 2 and 2.0-80.9mg copper powder (purity ≥ 99.99%, particle size 1 μm), in a glove box full of Ar gas (H 2 O2 x Nb 2 (0<x≤1.2) heterojunction materials.

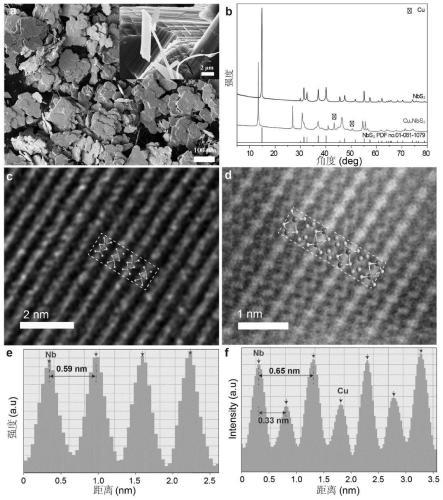

[0054] figure 1 Among (a) is the obtained NbS of the present embodiment 2 SEM image of the powder, NbS can be seen 2 is a typical two-dimensional layered material; figure 1 (b) is the XRD pattern obtained in this example, showing Cu and NbS 2 After the action, NbS 2 The (003) diffraction peaks of the NbS 2 The interlayer spacing increases, which may be caused by Cu atoms entering the interlayer. figure 1 (c) (d) (e) (f) is the NbS obtained in this embodiment 2 and Cu x Nb 2 The STEM image and...

Embodiment 2

[0057] Preparation of 2D Cu x TiS 2 The specific preparation method of the heterojunction material is as follows:

[0058] Step 1): Weigh 0.50g of metal Ti powder (purity ≥ 99.99%, particle size 325 mesh) and 0.69g of sublimated sulfur, in a glove box full of Ar gas (H 2 O2 2 compound.

[0059] Step 2): Weigh 100.0mg TiS 2 and 56.7mg of copper powder (purity ≥ 99.99%, particle size 1 μm), in a glove box full of Ar gas (H 2 O2 x TiS 2 heterojunction materials.

[0060] Figure 22 Among (a) is the obtained TiS of the present embodiment 2 SEM image of the powder, visible TiS 2 is a typical two-dimensional layered material; Figure 22 (b) is the XRD pattern obtained in this example, showing Cu and TiS 2 After the action, TiS 2 The (001) diffraction peaks of the TiS 2 The interlayer spacing increases, that is, Cu atoms enter the interlayer to form a two-dimensional heterojunction.

Embodiment 3

[0062] Preparation of 2D Cu x TT 2 The specific preparation method of the heterojunction material is as follows:

[0063] Step 1): take by weighing 0.50g metal Ta powder (purity ≥ 99.99%, particle diameter 325 orders) and 0.18g sublimated sulfur, in the glove box (H 2 O2 2 compound.

[0064] Step 2): Weigh 100.0mg TaS 2 and 25.9mg of copper powder (purity ≥ 99.99%, particle size 1μm), in a glove box full of Ar gas (H 2 O2 x TT 2 heterojunction materials.

[0065] Figure 23 Middle (a) is TaS obtained in the present embodiment 2 SEM image of powder, visible TaS 2 is a typical two-dimensional layered material; Figure 23(b) is the XRD pattern obtained in this example, showing Cu and TaS 2 After the action, TaS 2 The (001) diffraction peak of (001) is obviously shifted to a low angle, indicating that the interlayer spacing of TaS2 increases, that is, Cu atoms enter the interlayer to form a two-dimensional heterojunction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com