Novel two-dimensional heterojunction material and its preparation method

A two-dimensional heterojunction and heterojunction technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, vanadium compounds, etc., can solve the problem of low concentration, time-consuming, and inability to precisely control the concentration of metal atoms And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Preparation of 2D Cu x Nb 2 (0

[0052] Step 1): take by weighing 0.67g metal Nb powder (purity ≥ 99.99%, particle diameter 325 orders) and 0.48g sublimated sulfur, in the glove box (H 2 O2 2 compound.

[0053] Step 2): Weigh 100.0mg NbS 2 and 2.0-80.9mg copper powder (purity ≥ 99.99%, particle size 1 μm), in a glove box full of Ar gas (H 2 O2 x Nb 2 (0<x≤1.2) heterojunction materials.

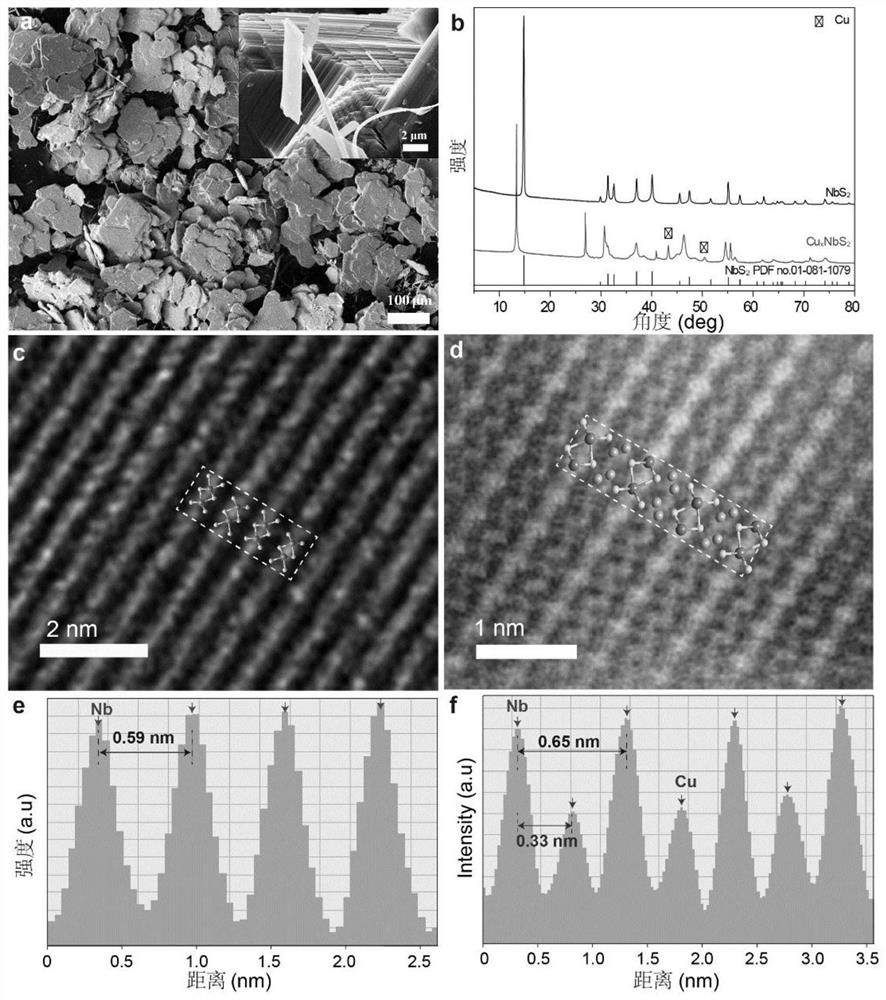

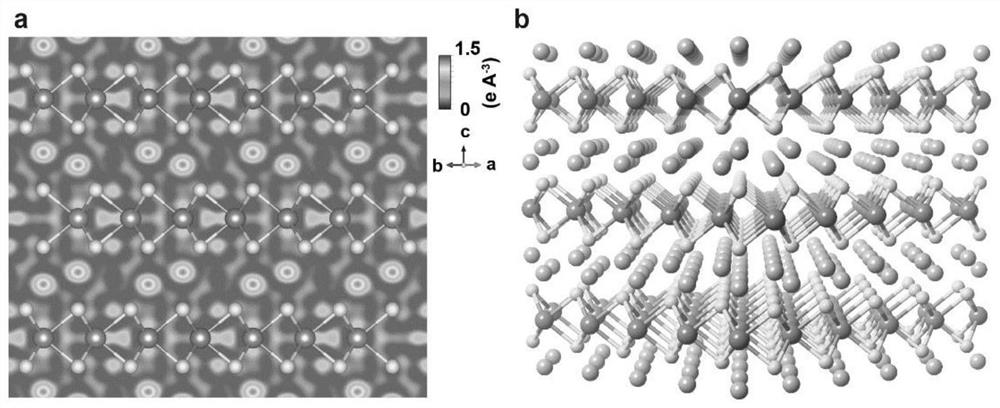

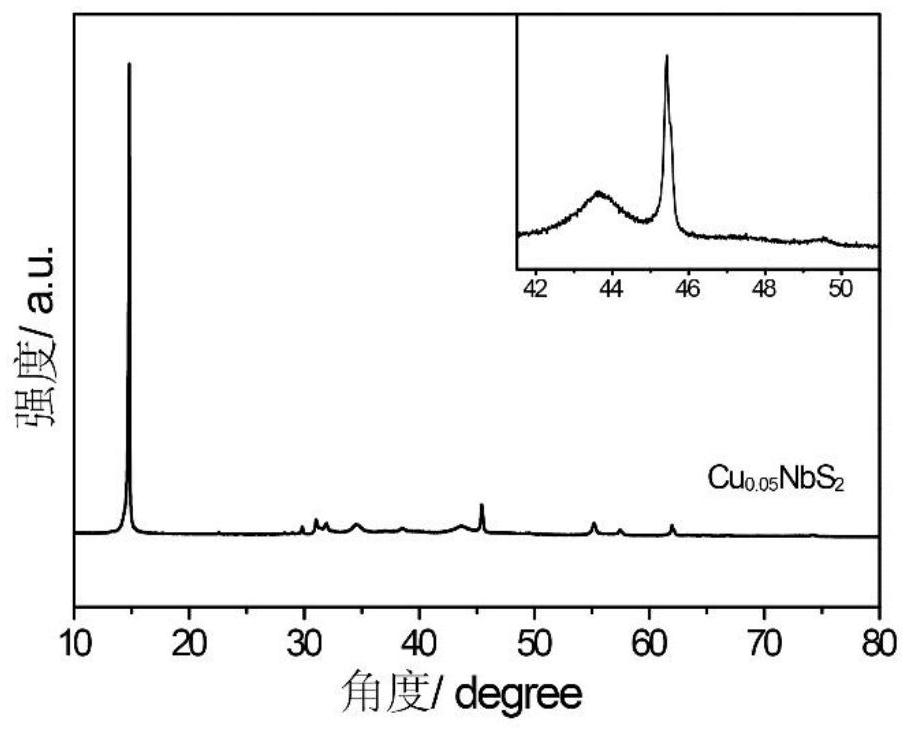

[0054] figure 1 Among (a) is the obtained NbS of the present embodiment 2 SEM image of the powder, NbS can be seen 2 is a typical two-dimensional layered material; figure 1 (b) is the XRD pattern obtained in this example, showing Cu and NbS 2 After the action, NbS 2 The (003) diffraction peaks of the NbS 2 The interlayer spacing increases, which may be caused by Cu atoms entering the interlayer. figure 1 (c) (d) (e) (f) is the NbS obtained in this embodiment 2 and Cu x Nb 2 The STEM image and...

Embodiment 2

[0057] Preparation of 2D Cu x TiS 2 The specific preparation method of the heterojunction material is as follows:

[0058] Step 1): Weigh 0.50g of metal Ti powder (purity ≥ 99.99%, particle size 325 mesh) and 0.69g of sublimated sulfur, in a glove box full of Ar gas (H 2 O2 2 compound.

[0059] Step 2): Weigh 100.0mg TiS 2 and 56.7mg of copper powder (purity ≥ 99.99%, particle size 1 μm), in a glove box full of Ar gas (H 2 O2 x TiS 2 heterojunction materials.

[0060] Figure 22 Among (a) is the obtained TiS of the present embodiment 2 SEM image of the powder, visible TiS 2 is a typical two-dimensional layered material; Figure 22 (b) is the XRD pattern obtained in this example, showing Cu and TiS 2 After the action, TiS 2 The (001) diffraction peaks of the TiS 2 The interlayer spacing increases, that is, Cu atoms enter the interlayer to form a two-dimensional heterojunction.

Embodiment 3

[0062] Preparation of 2D Cu x TT 2 The specific preparation method of the heterojunction material is as follows:

[0063] Step 1): take by weighing 0.50g metal Ta powder (purity ≥ 99.99%, particle diameter 325 orders) and 0.18g sublimated sulfur, in the glove box (H 2 O2 2 compound.

[0064] Step 2): Weigh 100.0mg TaS 2 and 25.9mg of copper powder (purity ≥ 99.99%, particle size 1μm), in a glove box full of Ar gas (H 2 O2 x TT 2 heterojunction materials.

[0065] Figure 23 Middle (a) is TaS obtained in the present embodiment 2 SEM image of the powder, visible TaS 2 is a typical two-dimensional layered material; Figure 23(b) is the XRD pattern obtained in this example, showing Cu and TaS 2 After the action, TaS 2 The (001) diffraction peak of (001) is obviously shifted to a low angle, indicating that the interlayer spacing of TaS2 increases, that is, Cu atoms enter the interlayer to form a two-dimensional heterojunction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com