Composite biological filter material

A biological filter material and filter material technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of non-adjustable porosity, difficulty in controlling filtration efficiency, and backwashing efficiency Low-level problems, to achieve the effect of improving the efficiency of film formation, improving sewage treatment capacity, and increasing the area of film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in conjunction with specific embodiment now.

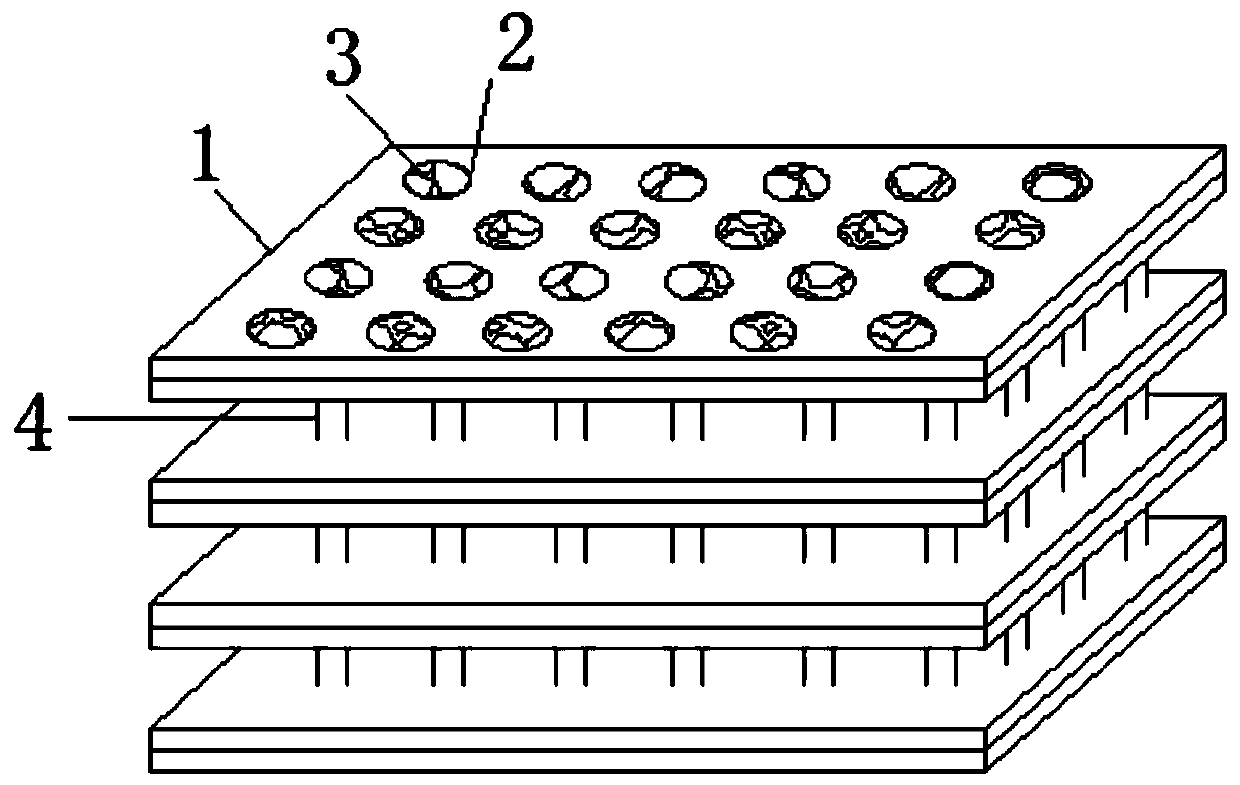

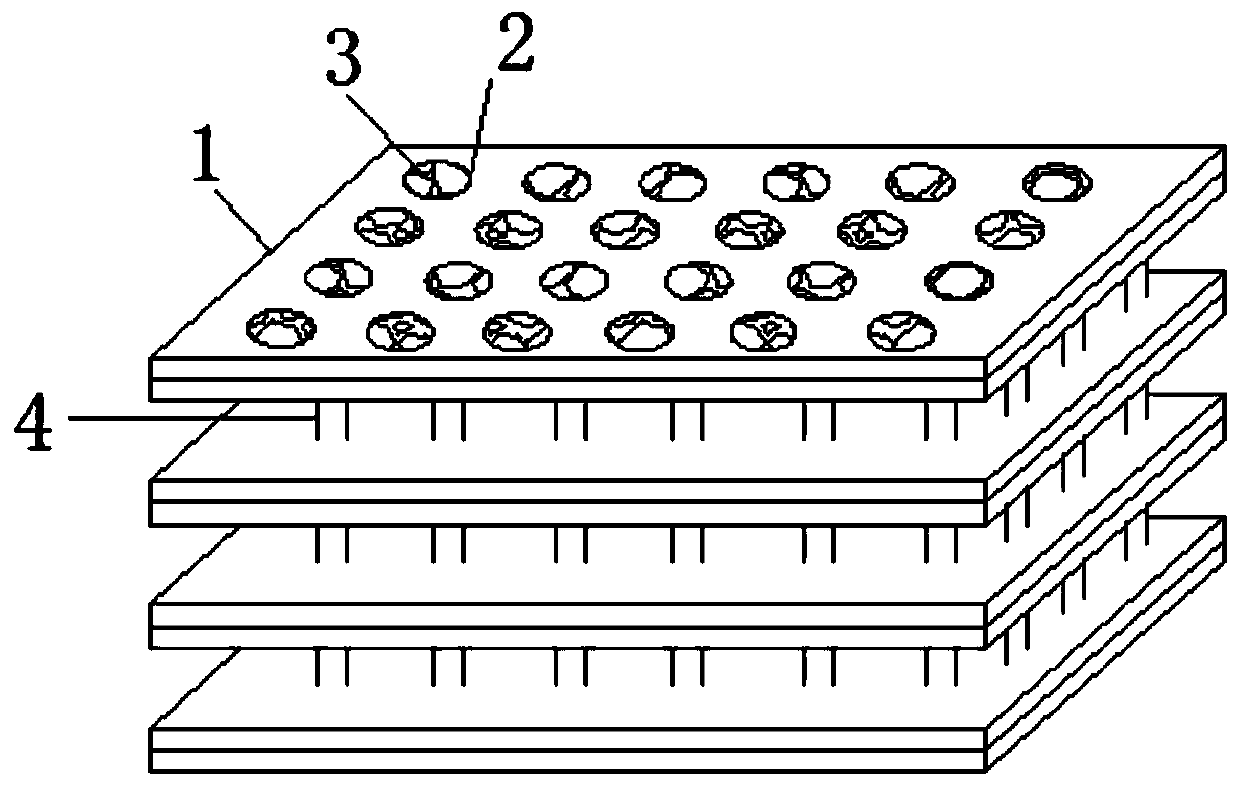

[0019] see figure 1 , a composite biological filter material, the composite biological filter material includes several layers of biological filter material stacked in sequence, each layer of biological filter material includes a basalt filter material 3 and a fixed frame 1 for fixing the basalt filter material 3, on the fixed frame 1 Evenly distributed with some fixing holes 2 for fixing the basalt filter material 3, the porosity of the basalt filter material 3 in several layers of biological filter material decreases successively from top to bottom, and the volume of the basalt filter material 3 in several layers of biological filter material decreases from Decreases from top to bottom, and the two adjacent fixed frames 1 are socketed through the fixed rod 4 and the fixed seat. With this structure, the installation and disassembly efficiency between the two adjacent fixed fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com