Water-soluble integrated zinc sulfate monohydrate granular fertilizer and preparation method thereof

A zinc sulfate and water-soluble technology, which is applied in the field of water-soluble integrated zinc sulfate monohydrate granular fertilizer and its preparation, can solve the problems of poor application effect and low activity, improve mixing and buffering properties, overcome antagonism, Good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

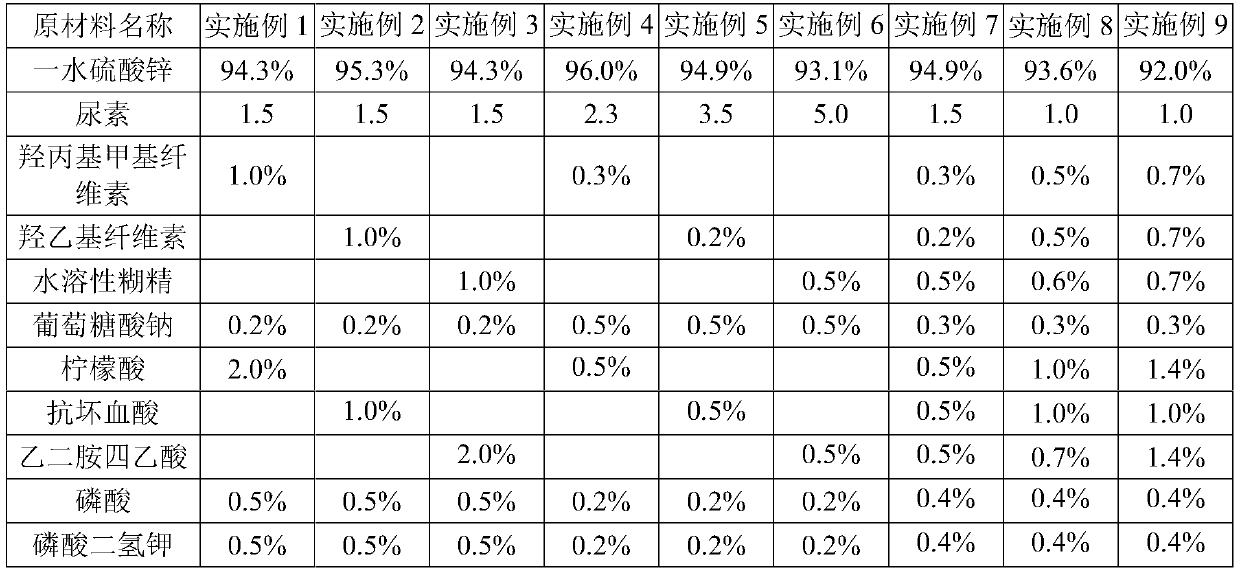

Embodiment 1

[0017] Each component is weighed by the formula of Example 1 in Table 1, and other components except zinc sulfate monohydrate are dissolved in water to be mixed with the solution that concentration is 20wt%, after the gained solution mixes with zinc sulfate monohydrate, press present There are conventional methods for granulation and drying at 80-90°C to obtain the water-soluble integrated zinc sulfate monohydrate granular fertilizer.

Embodiment 2

[0019] Take each component by the formula of embodiment 2 in table 1, and other components except zinc sulfate monohydrate are dissolved in water and be mixed with the solution that concentration is 25wt%, after the gained solution mixes with zinc sulfate monohydrate, press present There are conventional methods for granulation and drying at 80-90°C to obtain the water-soluble integrated zinc sulfate monohydrate granular fertilizer.

Embodiment 3

[0021] Each component is weighed by the formula of Example 3 in Table 1, and other components except zinc sulfate monohydrate are dissolved in water and are mixed with the solution that concentration is 30wt%, after the gained solution mixes with zinc sulfate monohydrate, press present There are conventional methods for granulation and drying at 95-105°C to obtain the water-soluble integrated zinc sulfate monohydrate granular fertilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com