LED light-cured film high-speed processing equipment, processing method and LED gloss oil

A processing equipment, light curing technology, applied in coatings, polyurea/polyurethane coatings, devices for coating liquids on surfaces, etc., can solve the problems of long curing time, low degree of integration, and unfriendly mercury lamps , to achieve the effect of fast curing speed, high degree of integration and fast processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings.

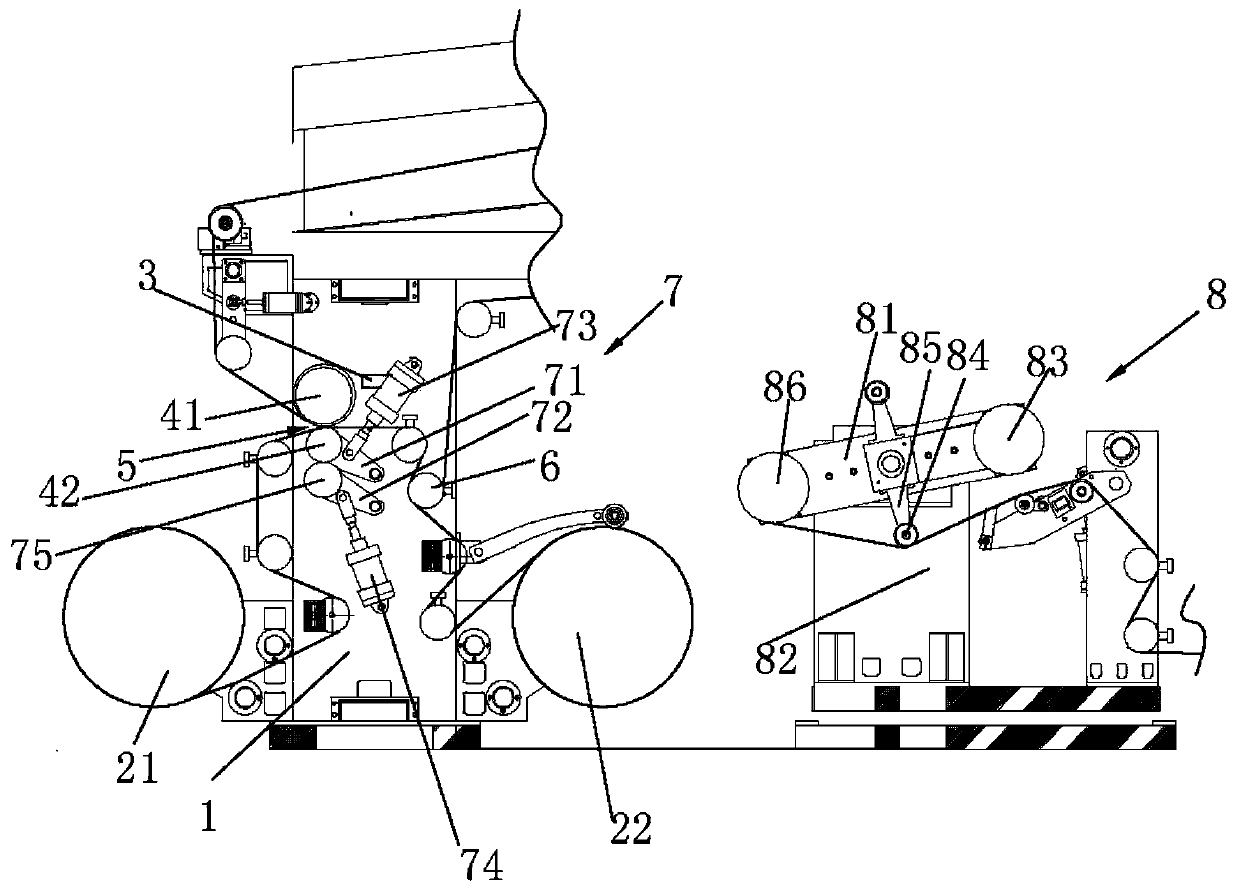

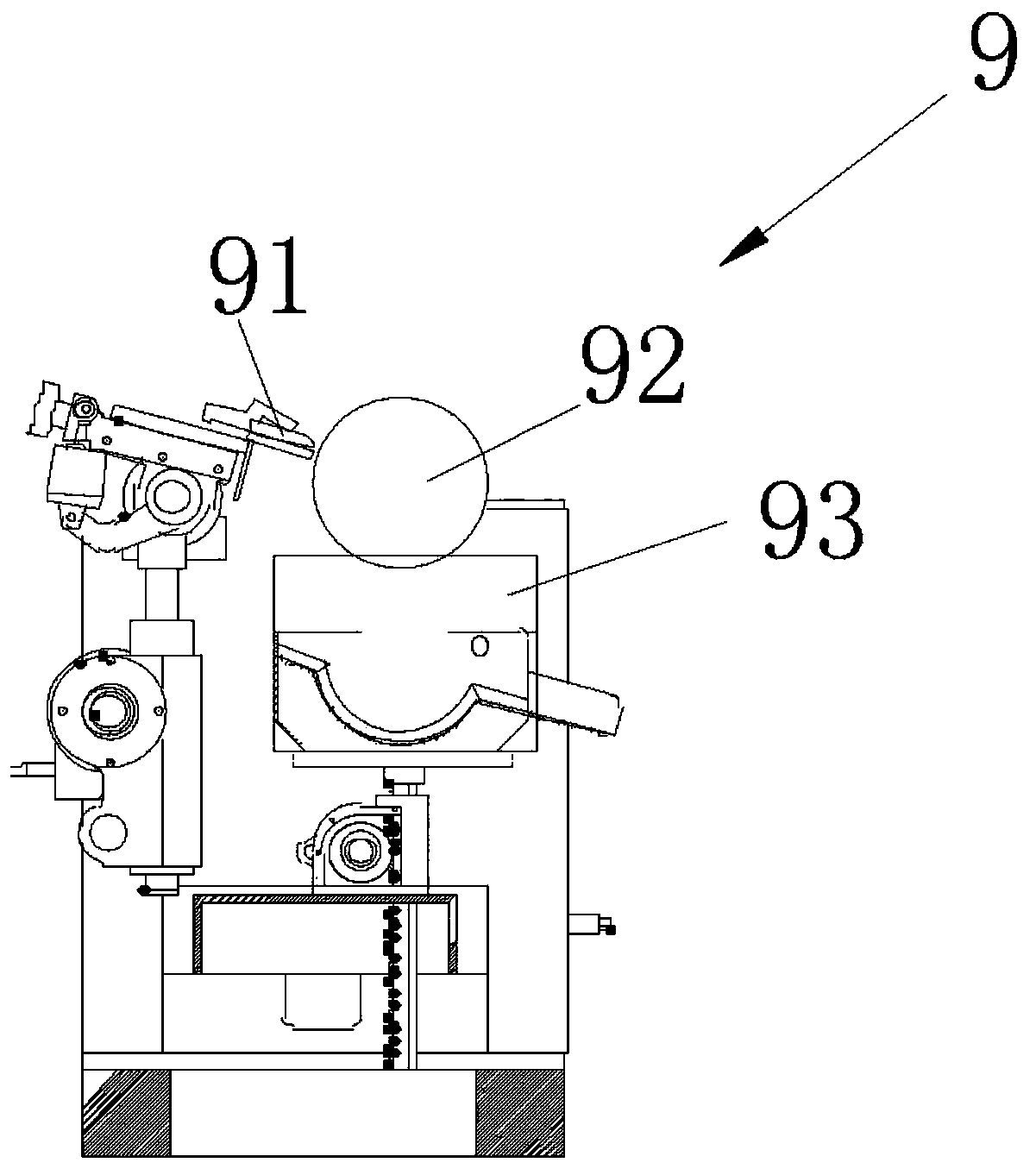

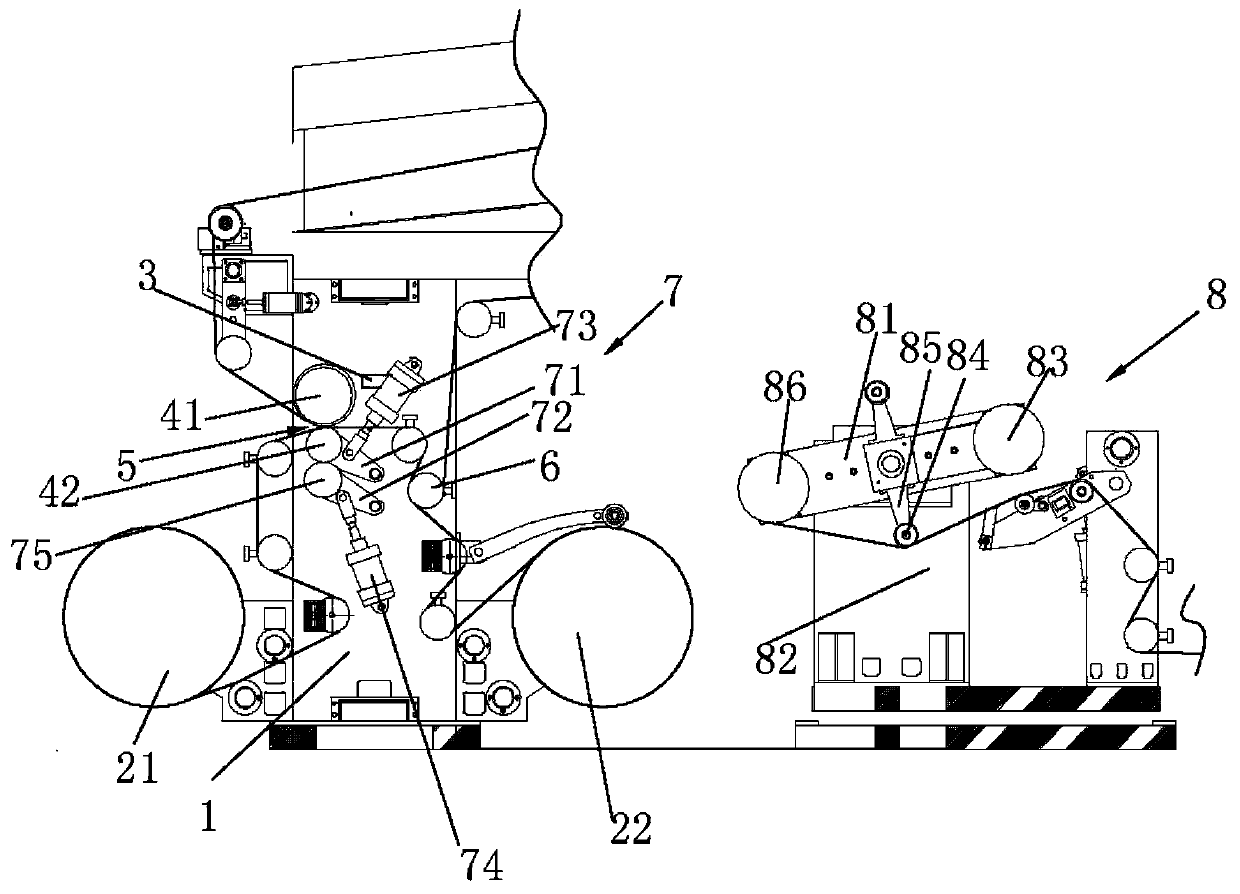

[0041] Such as figure 1 , figure 2 As shown, the LED light-cured film high-speed processing equipment of the present invention includes a frame 1, a first feeding roller 21 and a first receiving roller 22, and the first feeding roller 21 and the first receiving roller 22 are rotatably arranged The frame 1 also includes an LED light curing lamp 3, a closed pressure roller 41, a pressure station 5, a pressure support roller 42 and a peeling roller 6, and the closed pressure roller 41 and the peeling roller 6 are rotatably arranged on Frame 1, the pressing station 5 is arranged between the closed pressing roller 41 and the pressing support roller 42, and the irradiation range of the LED light curing lamp 3 is arranged between the pressing station 5 and the peeling roller 6; The second feeding roller 86 and the second receiving roller, the second feeding roller 86 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com