PU foam and manufacturing method thereof

A technology of foamed cotton and foamed glass, applied in adhesive types, film/sheet adhesives, polyurea/polyurethane adhesives, etc., which can solve uneven pores, high cost, and poor shockproof and waterproof effects Good and other problems, to achieve the effect of average hole distance and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

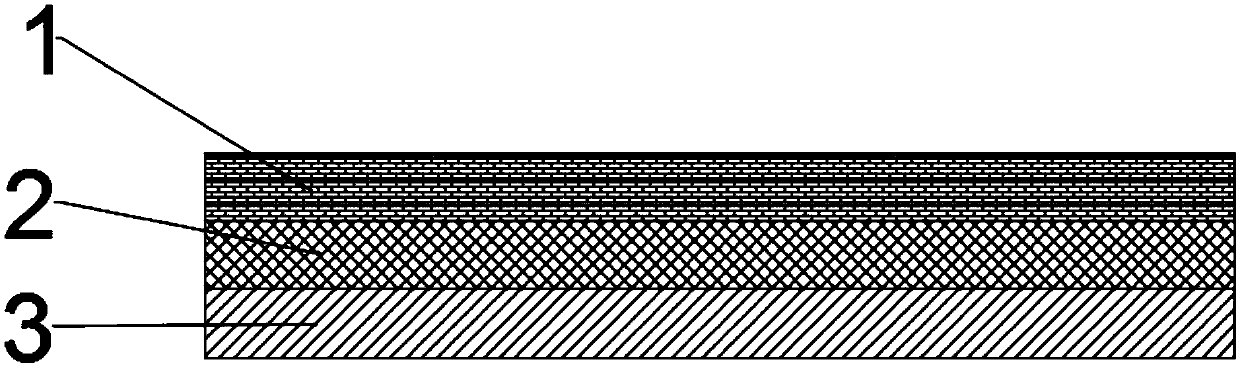

[0025] The PU foam provided by the present invention comprises a PET backing film layer 1, a PU foam layer 2 and a transparent single-sided release film protective layer 3 arranged in sequence from top to bottom; the PU foam layer 2 is made of PU adhesive, foamed glass bead powder, curing agent and antioxidant are mixed, wherein the PU adhesive is 96 parts; the foamed glass bead powder is 3 parts; the curing agent is 0.5 part; the antioxidant is 0.5 part.

[0026] The preparation method of processed foam is as follows:

[0027] Add the foamed glass bead powder of the weighed material to the stirring PU binder and stir it evenly, and the time is 20-40min to obtain the first mixture;

[0028] Filter the first mixture material with a 250-350 mesh filter;

[0029] After weighing the filtered first mixture, add it to the weighed and stirred PU binder and at the same time add the antioxidant, and stir at 300-400r / min for 20-40min to obtain the second mixture;

[0030] Add the weighed materi...

Embodiment 2

[0035] The PU foam provided by the present invention comprises a PET backing film layer 1, a PU foam layer 2 and a transparent single-sided release film protective layer 3 arranged in sequence from top to bottom; the PU foam layer 2 is made of PU adhesive, foamed glass bead powder, curing agent and antioxidant are mixed, wherein the PU adhesive is 95 parts; the foamed glass bead powder is 3 parts; the curing agent is 1 part; the antioxidant is 1 part.

[0036] The preparation method of processed foam is as follows:

[0037] Add the foamed glass bead powder of the weighed material to the stirring PU binder and stir it evenly, and the time is 20-40min to obtain the first mixture;

[0038] Filter the first mixture material with a 250-350 mesh filter;

[0039] After weighing the filtered first mixture, add it to the weighed and stirred PU binder and at the same time add the antioxidant, and stir at 300-400r / min for 20-40min to obtain the second mixture;

[0040] Add the weighed material c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com