A dual-functional electrolytic water electrode with superwetting property and its preparation method

An electrolyzed water, dual-function technology, applied in the field of nanomaterials, can solve the problems of not being able to maximize the utilization of active sites, hindering electrolyte mass transfer, blocking active sites, etc., to overcome the bubble shielding effect, promote rapid diffusion, The effect of reducing sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

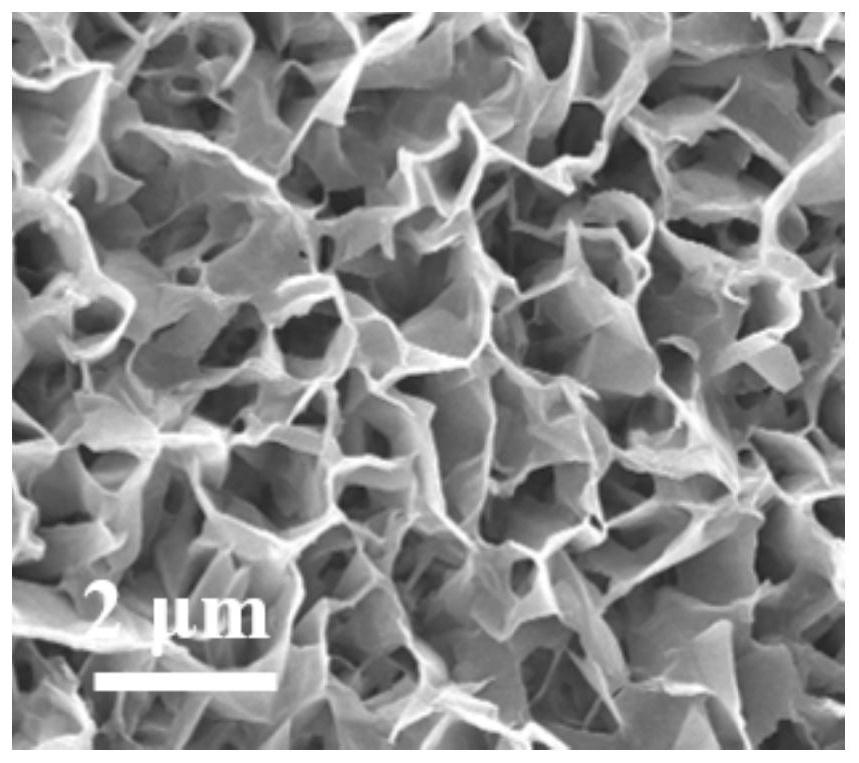

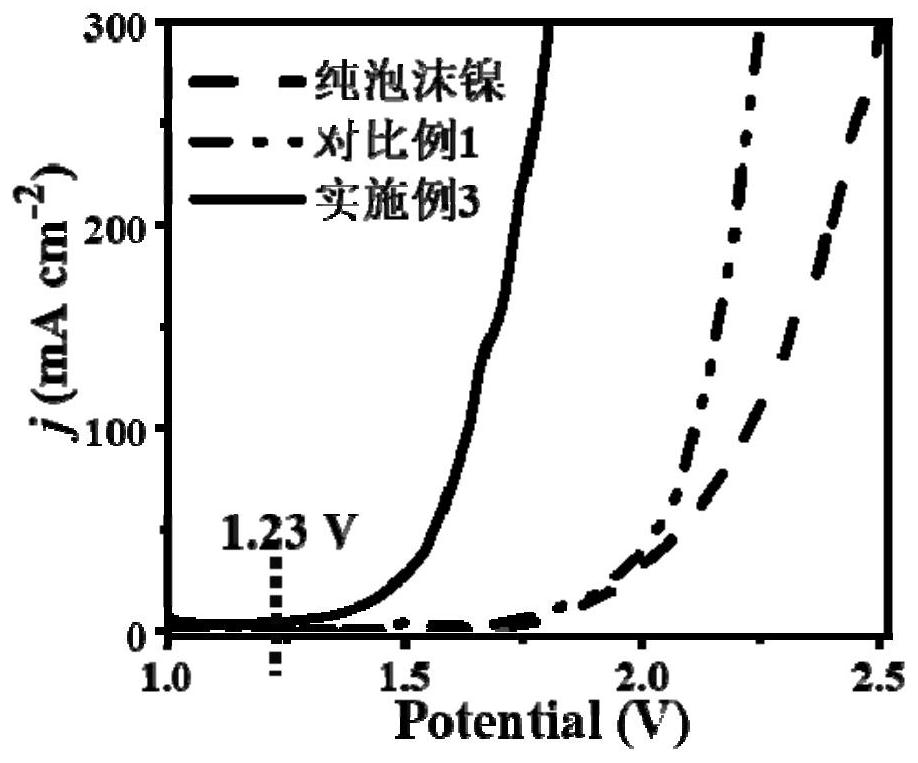

Embodiment 1

[0026] S1: Pretreatment of foamed nickel substrate: Cut the foamed nickel material into a sheet with a length of 2 cm and a width of 2 cm, then ultrasonically clean it with acetone and absolute ethanol for 3 minutes, and then put it in a vacuum drying oven at 50 ° C for 24 hours to obtain ; S2: Preparation of precursor solution: Dissolve cobalt acetate tetrahydrate and sodium sulfide nonahydrate in 15mol ultrapure water at a molar ratio of 5mmol:3mmol, and stir for 25min until dissolved to obtain a precursor solution; S3: Hydrothermal reaction: Transfer the precursor solution into a 50mL reaction kettle with a carrier nickel foam, and carry out a hydrothermal reaction at 100°C. After reacting for 8 hours, the product was collected by natural cooling, cleaned with deionized water and absolute ethanol, and removed. Vacuum drying, that is.

Embodiment 2

[0028] S1: Pretreatment of foamed nickel substrate: Cut the foamed nickel material into a sheet with a length of 5 cm and a width of 5 cm, then ultrasonically clean it with acetone and absolute ethanol for 10 minutes, and then put it in a vacuum drying oven at 70 ° C for 15 hours to obtain ; S2: Preparation of precursor solution: Dissolve cobalt acetate tetrahydrate and sodium sulfide nonahydrate in 51.35mol ultrapure water at a molar ratio of 5mmol:5mmol, and stir for 50min until dissolved to obtain a precursor solution; S3: hydrothermal reaction : Transfer the precursor solution into a 50mL reaction kettle with carrier foam nickel, carry out hydrothermal reaction at 200°C, after reacting for 3h, cool and collect the product naturally, wash the product with deionized water and absolute ethanol and remove It is vacuum-dried and obtained.

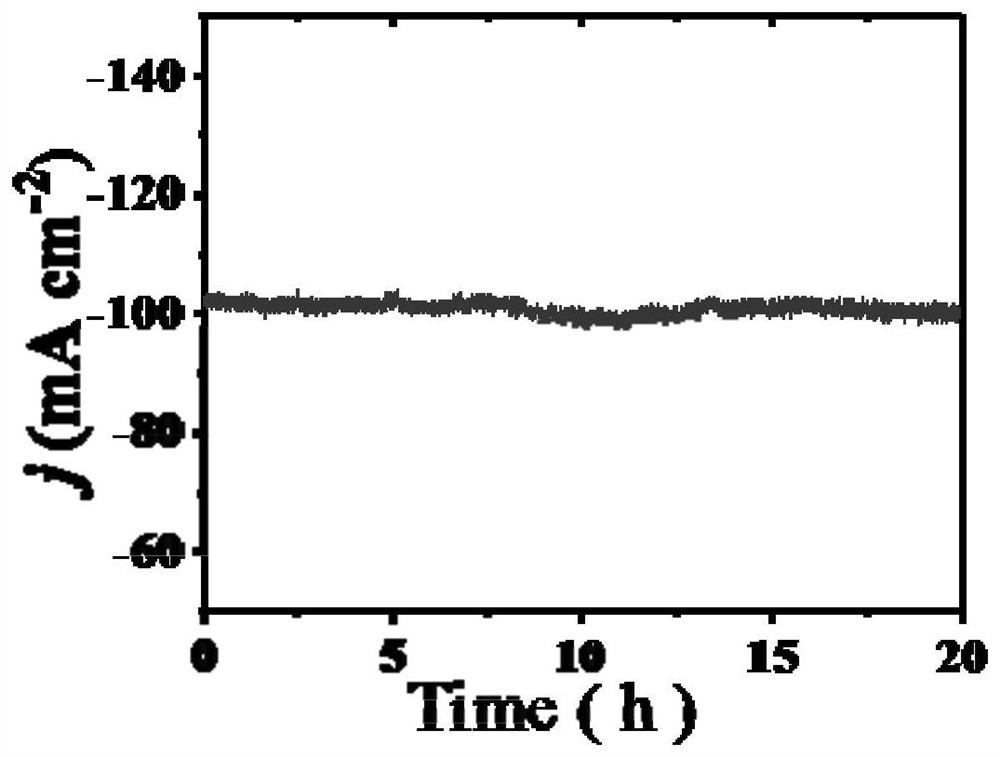

Embodiment 3

[0030] S1: Pretreatment of foamed nickel substrate: Cut the foamed nickel material into a sheet with a length of 2 cm and a width of 3 cm, then ultrasonically clean it with acetone and absolute ethanol for 5 minutes, and then put it in a vacuum oven at 60°C for 20 hours to get the final product. ; S2: Preparation of precursor solution: Dissolve cobalt acetate tetrahydrate and sodium sulfide nonahydrate in 22mol ultrapure water at a molar ratio of 5mmol: 4mmol, stir magnetically for 30min until dissolved, and obtain a precursor solution; S3: hydrothermal reaction : Transfer the precursor solution into a 50mL reaction kettle with carrier nickel foam, carry out hydrothermal reaction at 150°C, after reacting for 5h, cool and collect the product naturally, wash the product with deionized water and absolute ethanol and remove It is vacuum-dried and obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com