Double-power-source and double-anode electroplating device and method for filling through holes of glass adapter plate

A glass transfer plate and electroplating device technology, applied in the direction of electrodes, etc., can solve the problems of restricting the application and development of the transfer plate, high-efficiency filling of difficult inclined holes, immature electroplating process, etc., and achieve high-efficiency no-hole filling, guaranteeing Plating quality, effect of shortening plating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

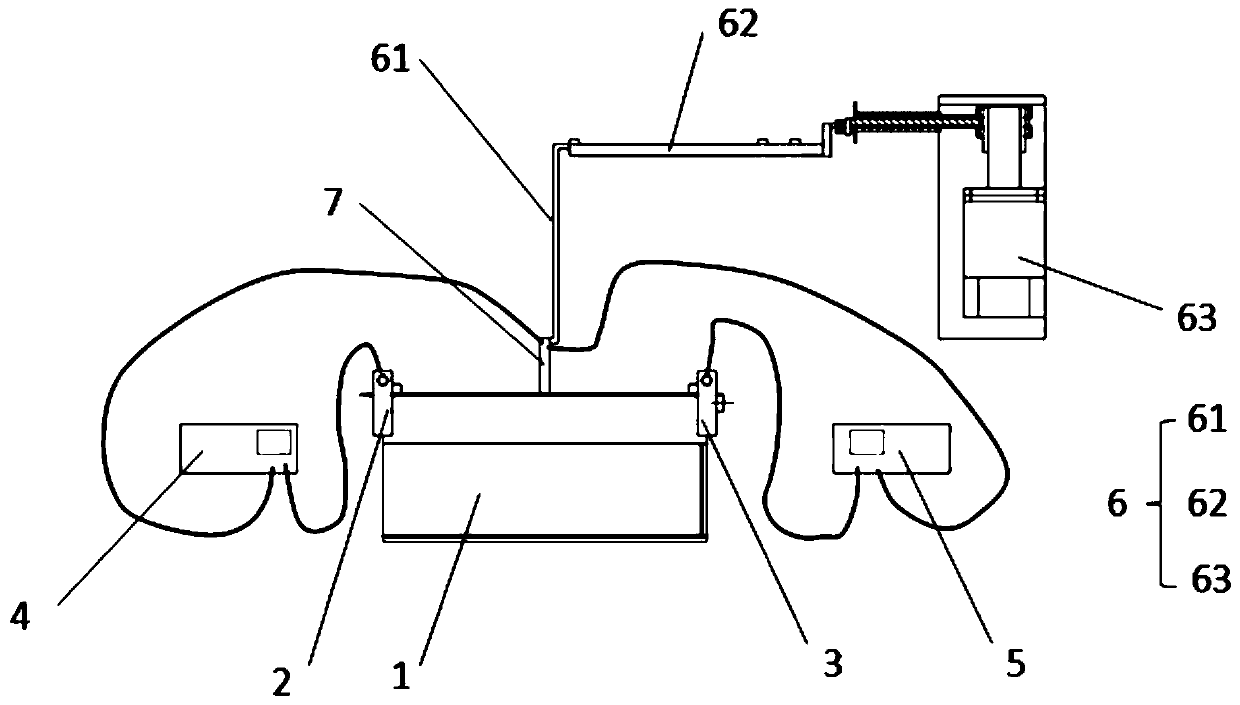

[0038] see figure 1 As shown, the present invention provides a double-power double-anode electroplating device for filling through holes of a glass adapter plate, including an electroplating tank 1 , a first anode 2 , a second anode 3 , a first power supply 4 and a second power supply 5 .

[0039] The electroplating tank 1 is used to hold an electroplating solution. In this embodiment, the electroplating solution is a copper plating solution provided by Shanghai Xinyang Semiconductor Materials Co., Ltd., and its model is SYSD 2110. In this embodiment, the electroplating solution contains additives, including accelerators, inhibitors and leveling agents, wherein the accelerator SPS content is 4 ppm, the leveling agent JGB is 5 ppm, and the inhibitor PEG is 300 ppm. By adding additives to adjust the metal deposition rate in different areas of the through hole, by suppressing the plating rate at the opening of the through hole by adding an inhibitor, avoiding the pre-sealing of t...

Embodiment 2

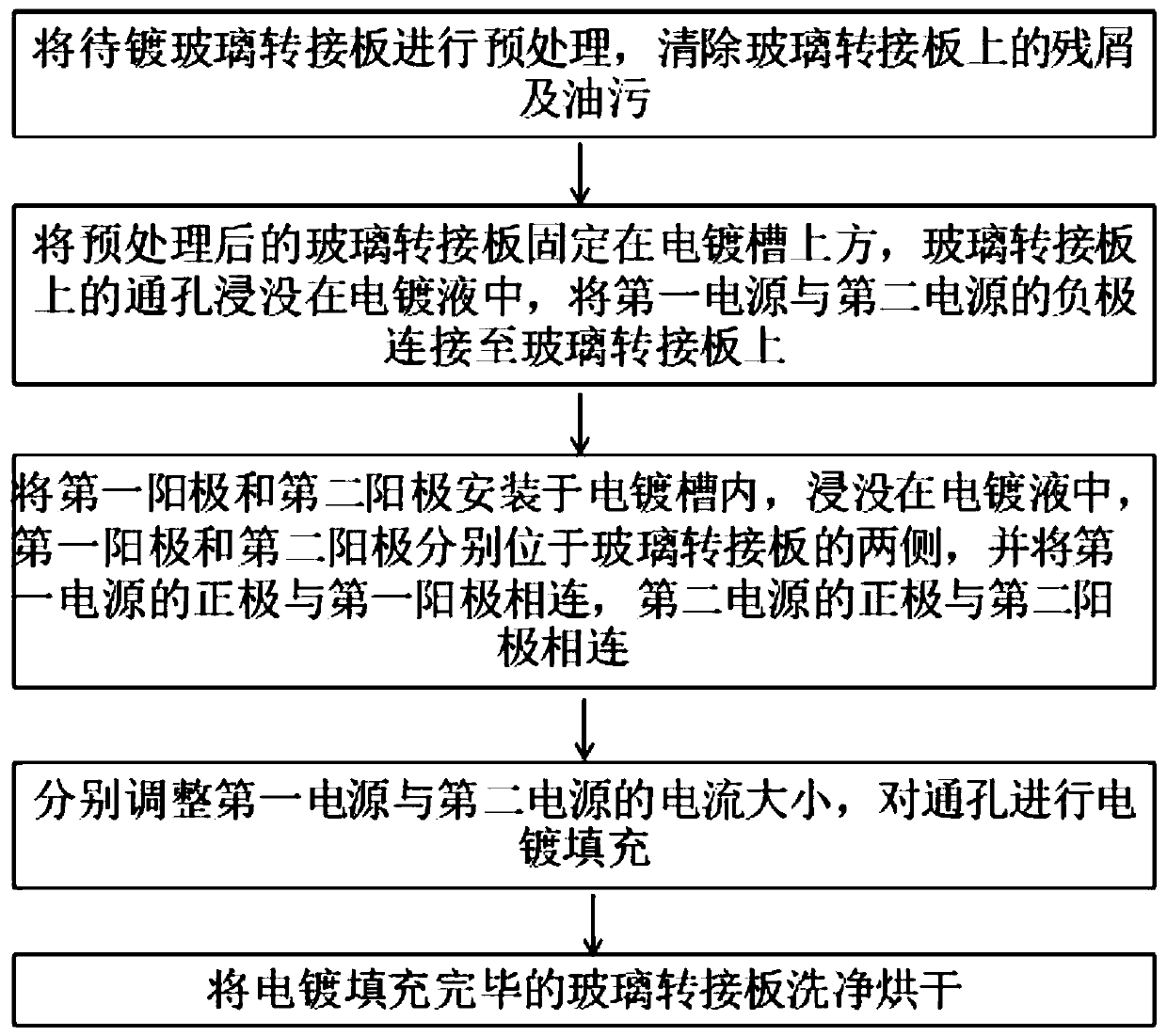

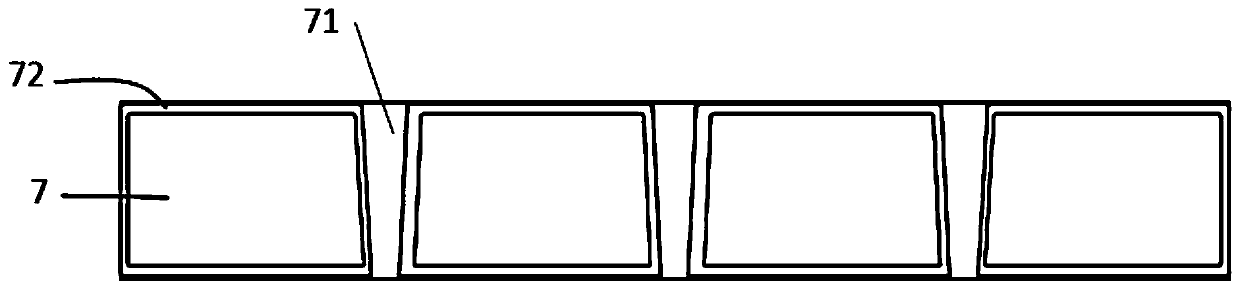

[0045] see figure 2 As shown, based on the same inventive concept, the present invention also provides a method for filling the through hole of the glass interposer, see image 3 as shown, image 3 It is a schematic cross-sectional view of the inclined hole of the glass adapter plate. The glass adapter plate 7 is provided with several through holes 71, and the through holes are inclined holes. In this embodiment, the diameters of the two ends of the inclined holes 71 are respectively 50 μm and 20 μm. The thickness of the glass adapter plate 7 is 150 μm, and the processing process of the through holes on the glass adapter plate 7 is as follows: firstly, a laser is used to process the glass through holes on the glass substrate, and then the surface of the glass substrate and the through holes are formed on the surface of the glass substrate by sputtering. A seed layer 72 is sputtered on the sidewall of the hole. In this embodiment, a copper seed layer is sputtered on the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com