Aircraft reconnaissance camera optical axis calibration device and method based on inertial navigation and optical measurement

A technology for optical measurement and calibration devices, applied in the direction of measuring devices, instruments, etc., can solve the problems of low precision, low efficiency, time-consuming and labor-intensive, etc., and achieve the effect of increasing the degree of automation, overcoming interpretation errors, and convenient and quick use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

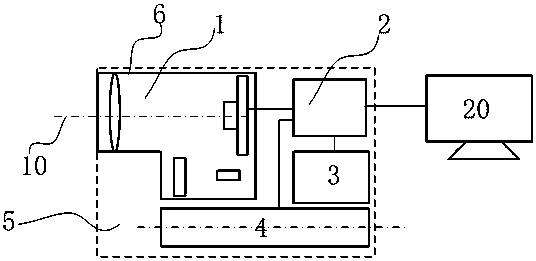

[0039] Such as Figure 1-5 As shown, the comprehensive target calibration system is composed of a comprehensive target calibration instrument host, a main control unit 20, a reference plane mirror 61 and its tooling, a weapon system adapter, a tripod and connecting cables.

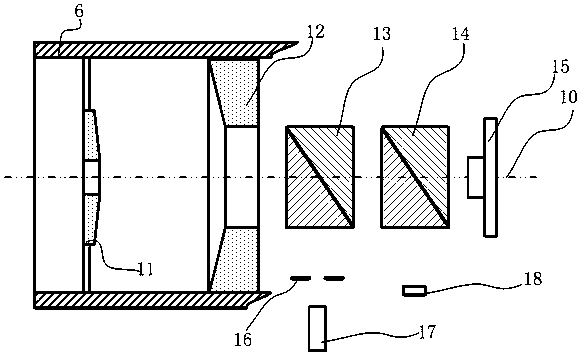

[0040] figure 2 Among them, the host of the comprehensive target calibration instrument includes an optical system 1 installed inside the casing 5, an image processing unit 2, a display screen 3 and an inertial measurement instrument 4; be consistent.

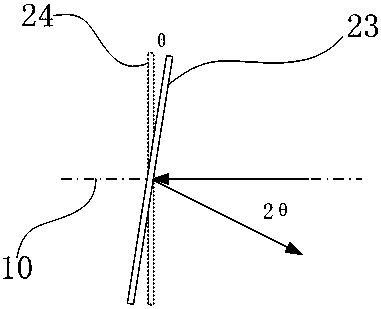

[0041]The optical system 1 comprises a secondary mirror 11, a primary mirror 12, a first cemented half mirror prism 13, a second cemented half mirror prism 14 and an image sensor 15 coaxially arranged in sequence according to the optical axis 10 direction, and the secondary mirror 11 and the primary mirror 12 are both It is a hollow structure, and the focusing lens group is formed on the spatial position; on the reflected light paths of the first cemente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com