Mould-proof and insect-proof tobacco leaf storage method

A tobacco leaf and insect control technology, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of difficult to achieve ideal storage environment conditions, unsatisfactory fumigation and insecticidal effect, and mildew of tobacco leaves, so as to optimize environmental factor indicators and eliminate tobacco leaves. Mildew and oxidative deterioration, and the effect of preventing and controlling tobacco leaf pests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A mildew-proof and insect-proof storage method for tobacco leaves, comprising the following steps:

[0027] (1) Isolate and clean the storage warehouse of tobacco leaf raw materials, and seal the doors, windows, floor windows, floor drains, floor seams, and expansion joints in the warehouse;

[0028] (2) Standardize the stacking of the tobacco leaves, and seal the stack with an insect-proof composite film composed of 4-6 layers of polyethylene film with a thickness of 0.01mm to form a sealed curtain, and a suction is preset on one side of the sealed curtain There are 2-4 air inlets on the other side, and the suction port and the air inlet can be connected to the fixed poisonous gas filter absorption tower outside the warehouse to fumigate and kill insects on the sealed smoke;

[0029] (3) Isolate the sealed cigarette stack after fumigation, put the tobacco insect lure core and tobacco leaf protective agent in the sealed tobacco stack; wherein the tobacco leaf protective...

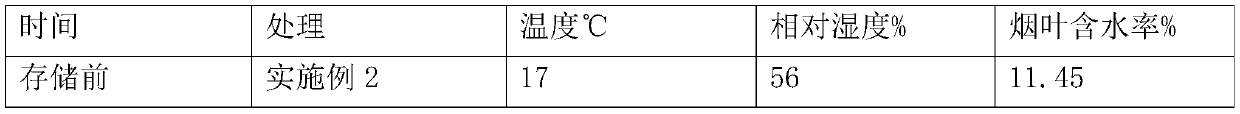

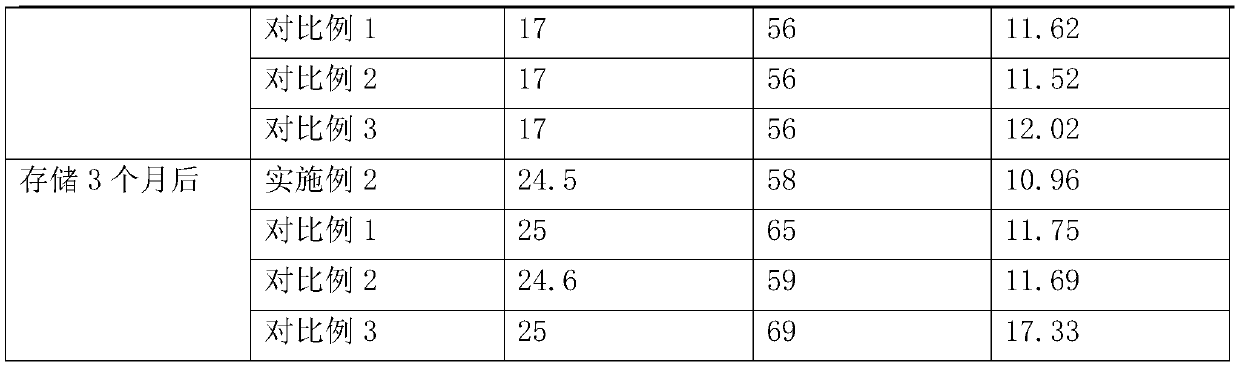

Embodiment 2

[0032] A mildew-proof and insect-proof storage method for tobacco leaves, comprising the following steps:

[0033] (1) Isolate and clean the storage warehouse of tobacco leaf raw materials, and seal the doors, windows, floor windows, floor drains, floor seams, and expansion joints in the warehouse;

[0034] (2) Standardize the stacking of the tobacco leaves, and seal the stack with an insect-proof composite film composed of 4-6 layers of polyethylene film with a thickness of 0.01mm to form a sealed curtain, and a suction is preset on one side of the sealed curtain There are 2-4 air inlets on the other side, and the suction port and the air inlet can be connected to the fixed poisonous gas filter absorption tower outside the warehouse to fumigate and kill insects on the sealed smoke;

[0035] (3) Isolate the sealed cigarette stack after fumigation, put the tobacco insect lure core and tobacco leaf protective agent in the sealed tobacco stack; wherein the tobacco leaf protective...

Embodiment 3

[0038] A mildew-proof and insect-proof storage method for tobacco leaves, comprising the following steps:

[0039] (1) Isolate and clean the storage warehouse of tobacco leaf raw materials, and seal the doors, windows, floor windows, floor drains, floor seams, and expansion joints in the warehouse;

[0040] (2) Standardize the stacking of the tobacco leaves, and seal the stack with an insect-proof composite film composed of 4-6 layers of polyethylene film with a thickness of 0.01mm to form a sealed curtain, and a suction is preset on one side of the sealed curtain There are 2-4 air inlets on the other side, and the suction port and the air inlet can be connected to the fixed poisonous gas filter absorption tower outside the warehouse to fumigate and kill insects on the sealed smoke;

[0041] (3) Isolate the sealed cigarette stack after fumigation, put the tobacco insect lure core and tobacco leaf protective agent in the sealed tobacco stack; wherein the tobacco leaf protective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com