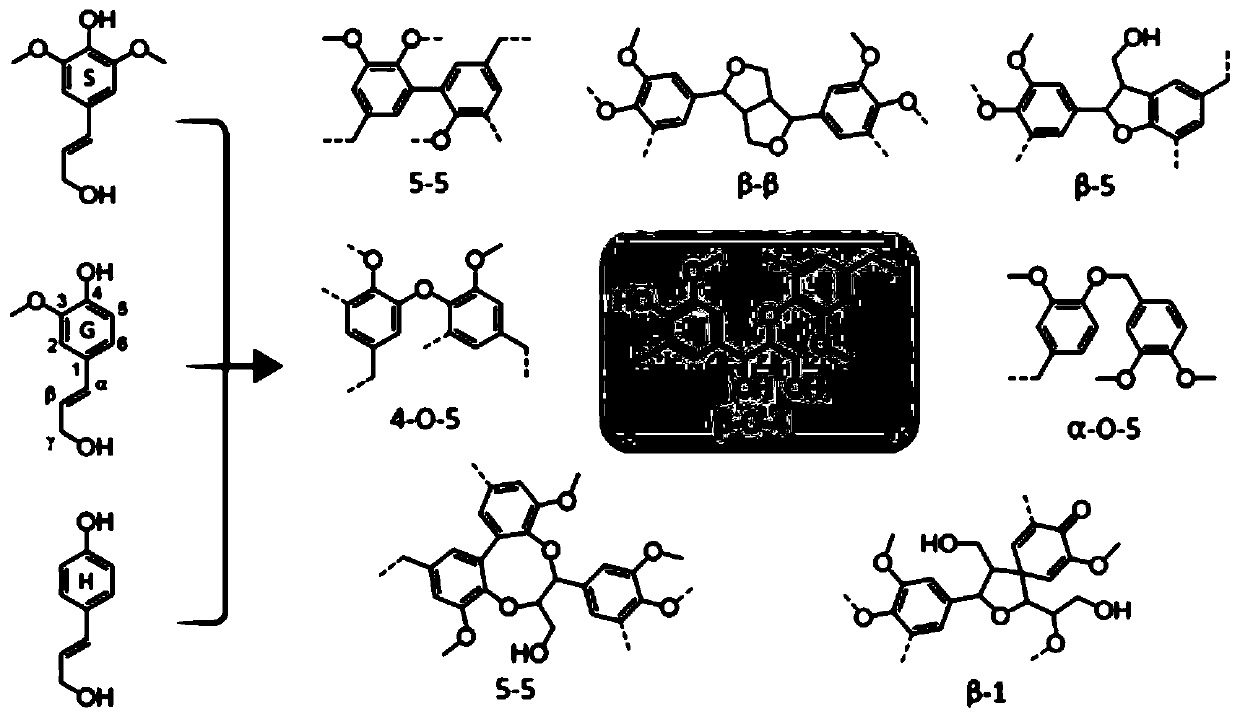

Ruthenium and tungsten modified metal solid solution catalyst, and preparation method and lignin depolymerization method thereof

A solid solution and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, oxygen-containing compound preparation, chemical instruments and methods, etc., can solve the problems of difficult product control, complex product types, and complicated post-processing, etc. To achieve the effect of reducing damage, environmental friendliness, and simple separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

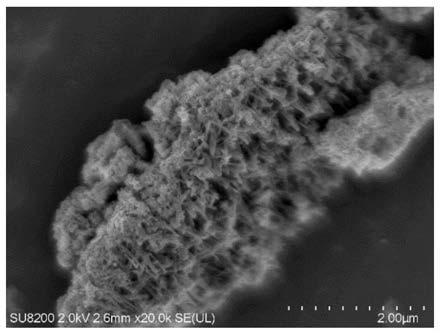

[0039] Correspondingly, an embodiment of the present invention provides a method for preparing a ruthenium and tungsten modified metal solid solution catalyst, comprising the following steps:

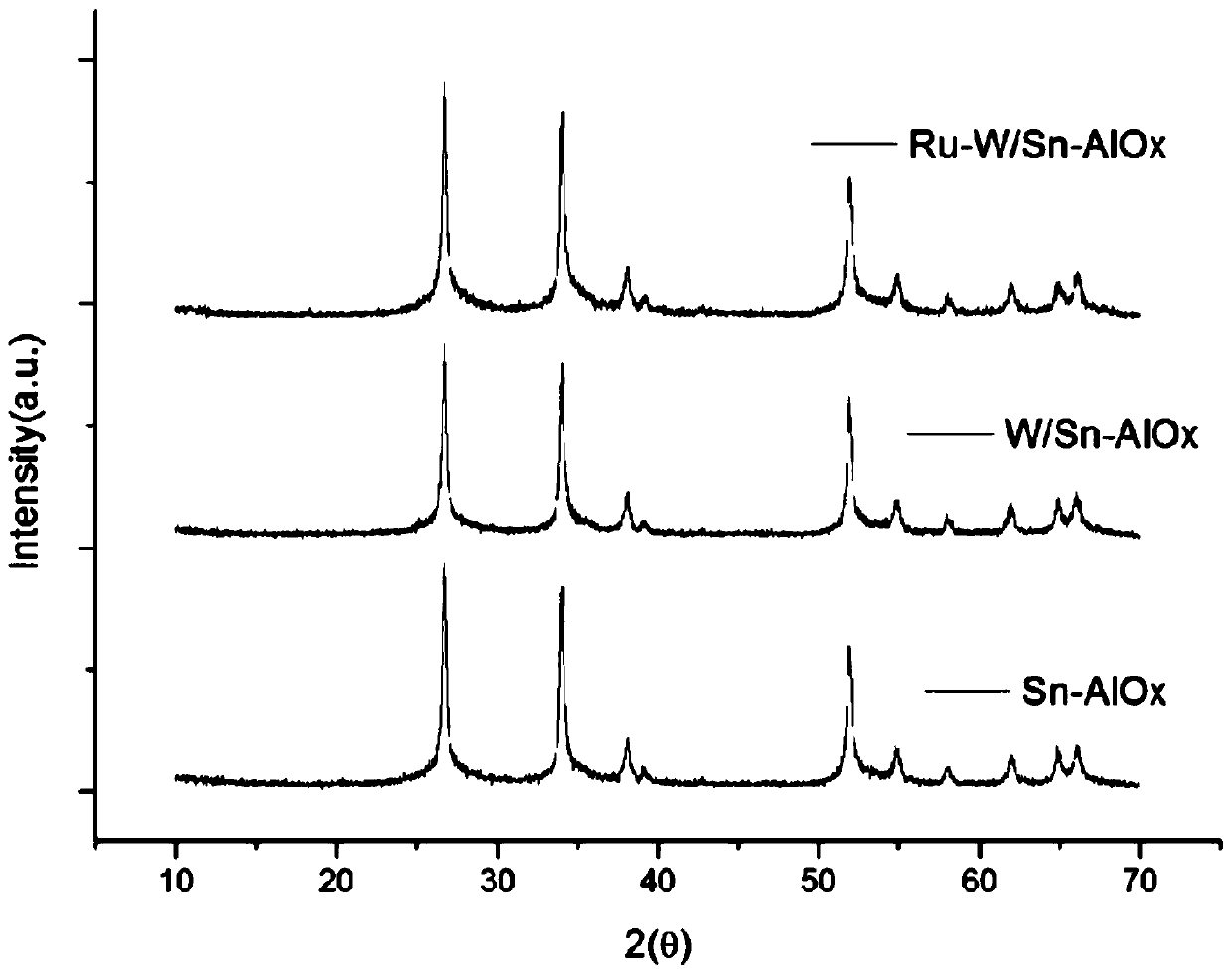

[0040]In the first step, the tin source and the aluminum source are mixed in the first solvent, and the precipitate is obtained by adjusting the pH value, and the precipitate is dried, calcined, and ground to obtain tin-aluminum oxide;

[0041] In the second step, the tin-aluminum oxide and the tungsten source are mixed in a second solvent, and then dried, calcined, and ground in sequence to obtain tungsten-modified tin-aluminum oxide;

[0042] In the third step, the tungsten-modified tin-aluminum oxide and the ruthenium source are mixed in a third solvent, and then reduced with a reducing agent to obtain a metal solid solution catalyst modified by ruthenium and tungsten.

[0043] Using the catalyst prepared in the embodiment of the present application to catalyze the depolymerization o...

Embodiment 1

[0070]The first step, stirring and dissolving 15.381g of tin chloride and 19.732g of aluminum nitrate in 50mL of water, using sodium hydroxide solution to adjust the pH to 12, precipitate, filter, and wash the precipitate with distilled water until the pH value is 7-8 In between, stir at room temperature for 3h. The washed solid phase was dried at 80°C for 10h, calcined at 550°C for 3h, and ground.

[0071] In the second step, mix 8g of the oxide obtained in the first step with 1.126g of phosphotungstic acid in 50mL of water, stir at 80°C for 3h, then dry at 80°C for 10h, calcinate at 500°C for 3h, and grind.

[0072] In the third step, 8g of the oxide obtained in the second step and 0.8208g of ruthenium chloride are stirred and mixed in 50mL solvent (a mixed solution of water and ethanol with a volume ratio of 1:1), and 16g of excess sodium borohydride is dropped into it for reduction, at room temperature Stir and reduce for 8h (the reduction parameters in the following exam...

Embodiment 2

[0098] The specific reaction process and detection method are the same as those of Comparative Example 3, except that the input catalyst is 0.1 g of the catalyst prepared in Example 1. The results showed that the yield of aromatic compounds was 7.48%; the yield of petroleum ether extract was 20.19%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap