A group of narrow groove electrolytic grinding and milling processing devices and methods thereof

A processing method, grinding and milling technology, applied in the direction of electric processing equipment, accessory devices, metal processing equipment, etc., can solve the problems of low processing accuracy, stray corrosion, difficult clamping, etc., to achieve flexible processing and use, and small stray corrosion , the effect of high surface strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

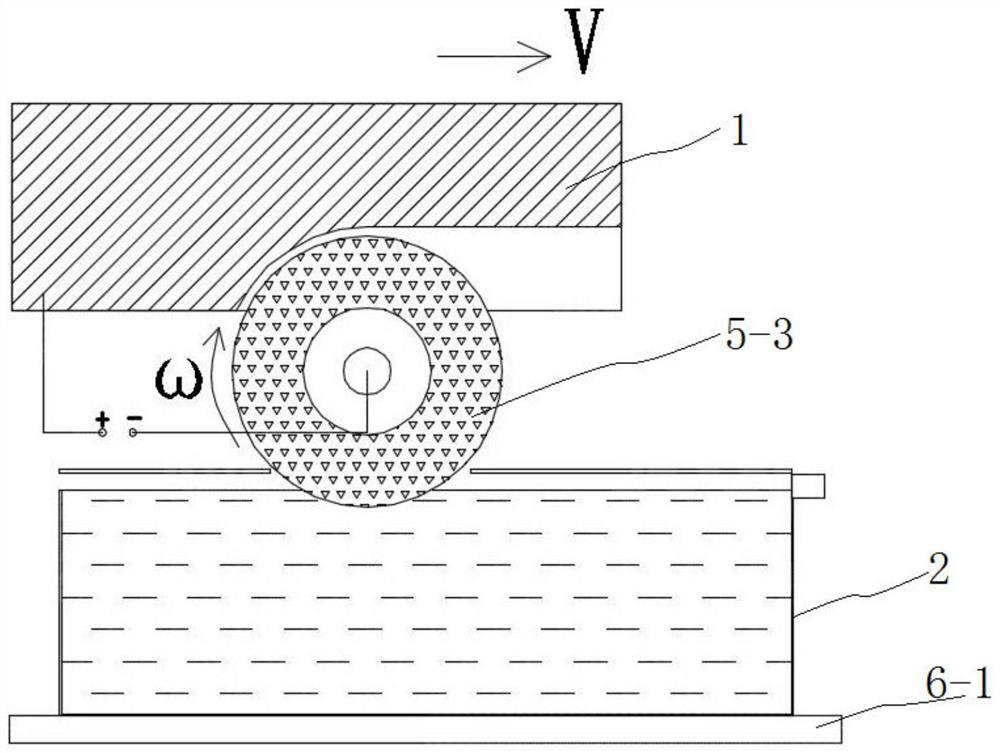

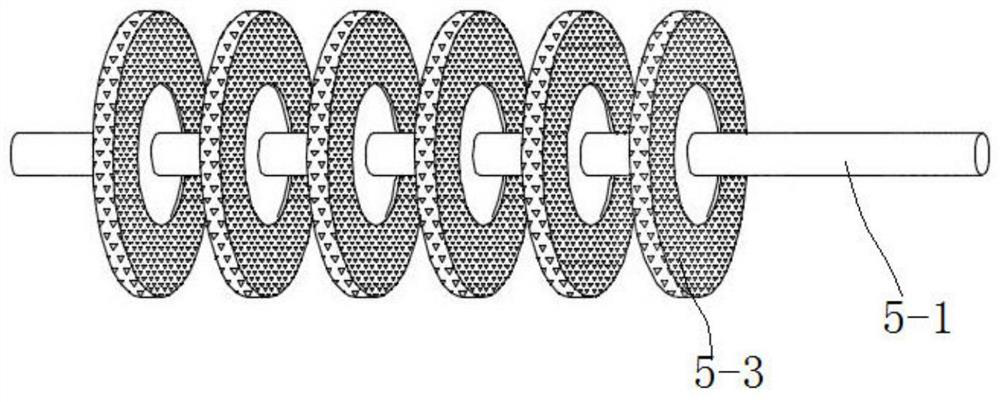

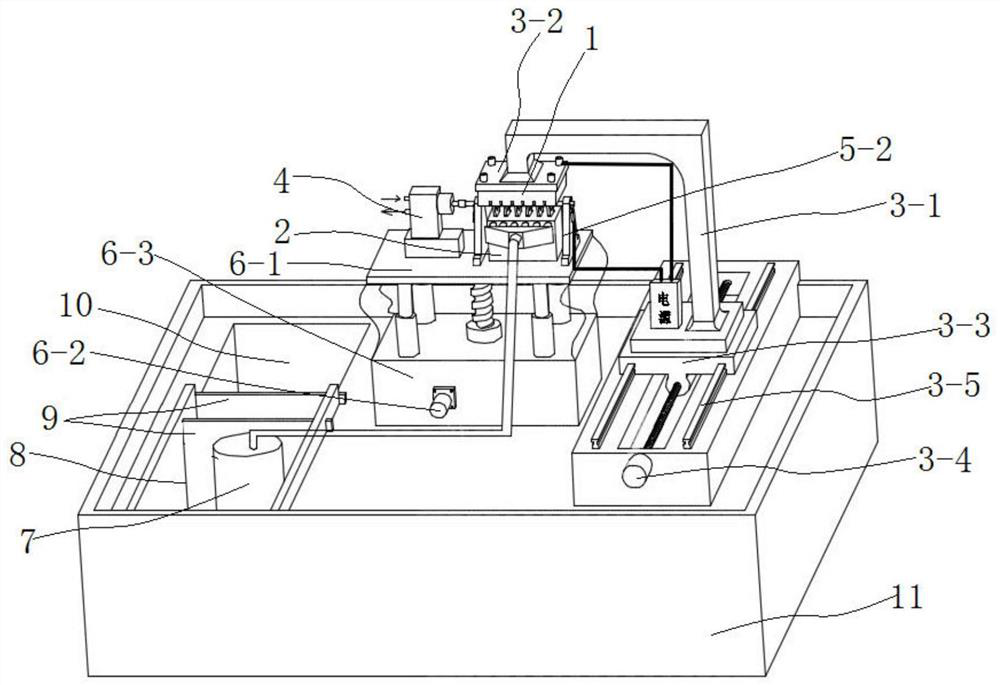

[0032] combine image 3 , a group of narrow groove electrolytic grinding and milling processing devices of the present embodiment, including a power supply and a workpiece 1 arranged in sequence from top to bottom, a group of composite grinding wheels for processing narrow grooves on the surface of the workpiece 1 to be processed, and an electrolyte tank 2, The processing surface of the workpiece 1 is arranged downward, and the workpiece 1 is driven by the forward and backward moving mechanism to move along the X-axis direction. The forward and backward moving mechanism is any mechanism that can control the movement of the workpiece along the X-axis direction. Screw rod type linear slide table, workpiece mounting base 3-1 and workpiece mounting table 3-2 arranged horizontally, workpiece mounting base 3-1 includes a first column, a beam and a second column, and the upper surface of workpiece mounting table 3-2 The first column is fixedly connected with one end of the beam, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com