A kind of 3d printing equipment, 3d printing system and 3d printing method

A 3D printing and equipment technology, applied in the field of 3D printing, can solve the problems of not being able to meet the construction period, deep processing of components, and parallel printing of multiple processes, so as to improve the comprehensive utilization efficiency of materials, increase the speed of 3D printing, and reduce construction costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Such as Figure 4 As shown, the 3D printing system in the embodiment of the present invention is a building construction automation system, which includes a steel bar printing assembly, an outline printing assembly, an SCC filling assembly, a wall painting assembly, a floor tile paving assembly, and a water and electricity pipeline assembly. Cheng et al., the so-called assembly refers to a complete set of printing construction equipment for this type of construction process. Each assembly can include one or more 3D printing devices.

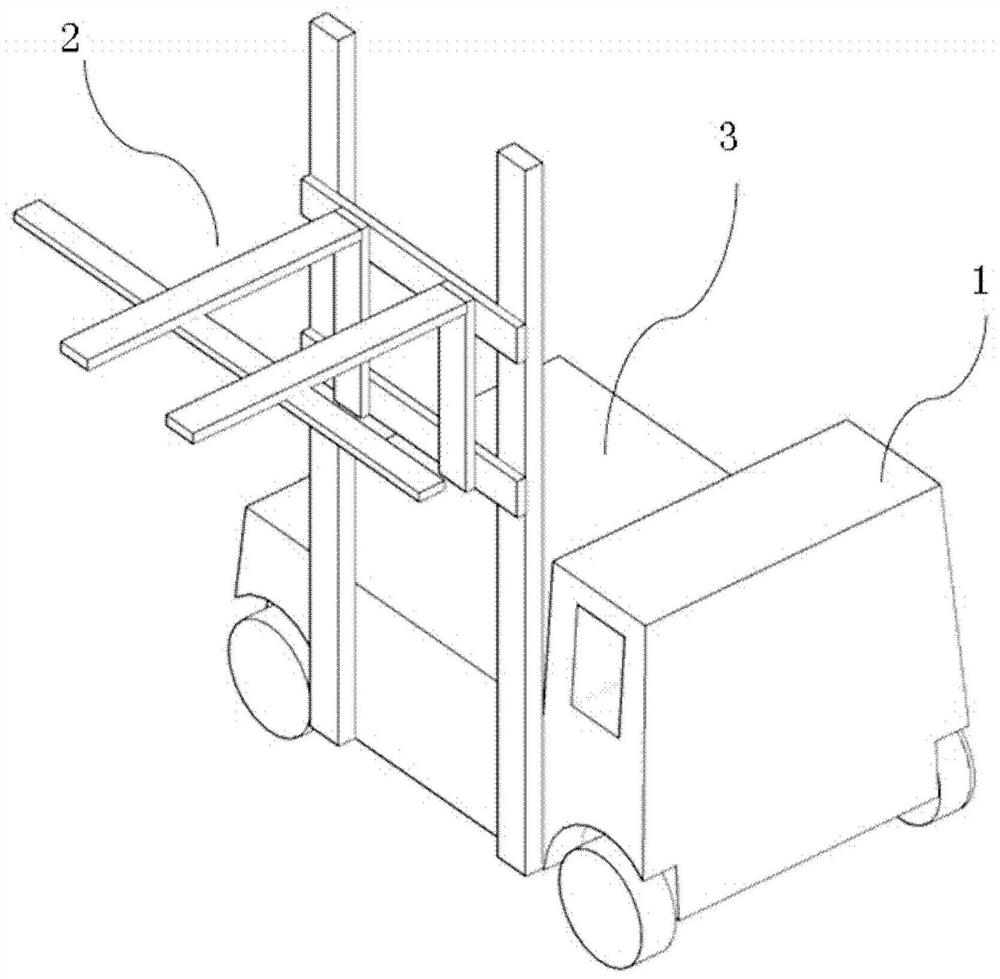

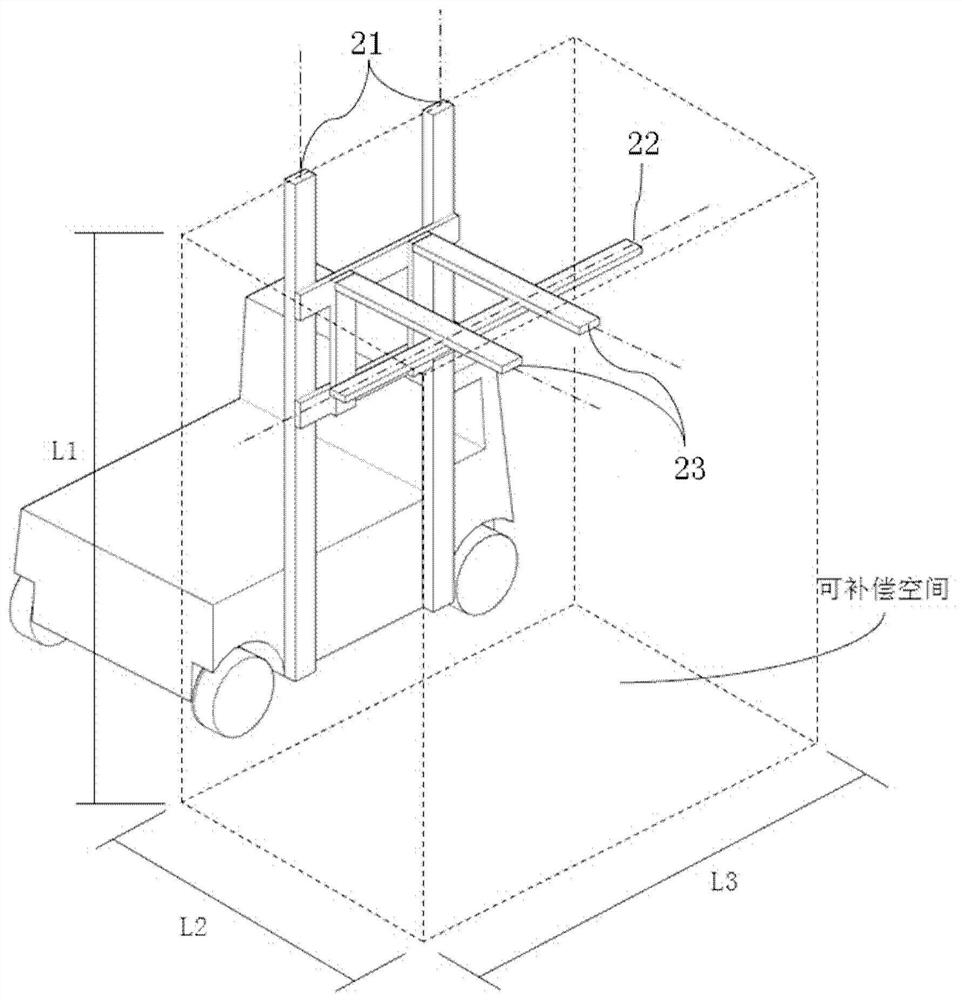

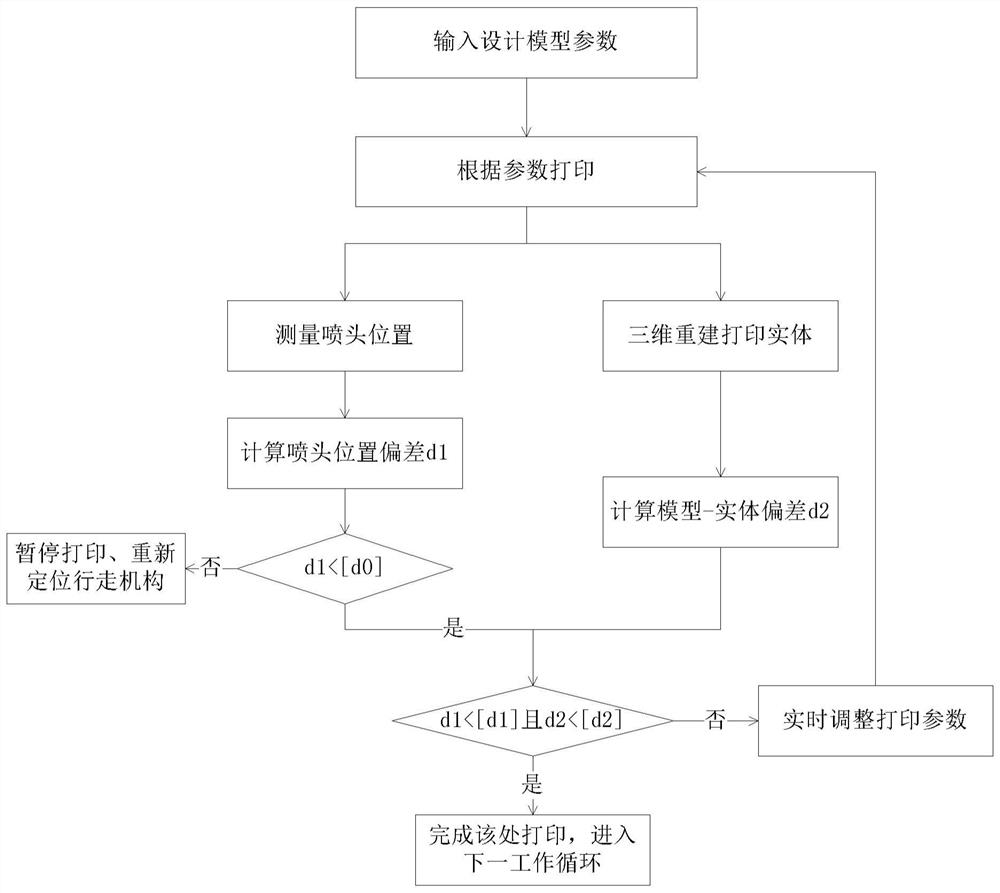

[0067] In an embodiment of the present invention, the 3D printing system of the present invention is used to realize 3D printing of buildings. Such as Figure 5 and 6 As shown, when printing the wall, the 3D printing equipment has a track-type walking mechanism, which can move along the length of the wall. With the movement of the walking mechanism, the printing nozzle also moves accordingly, realizing large-scale wall Print. When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com