Preparation method of tensile optical fiber

A technology of optical fiber and tensile strength, which is applied in the field of preparation of tensile optical fiber, can solve the problem that the strength is difficult to meet the use requirements, and achieve the effect of reducing the generation of micro-cracks on the quartz surface and enhancing the tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

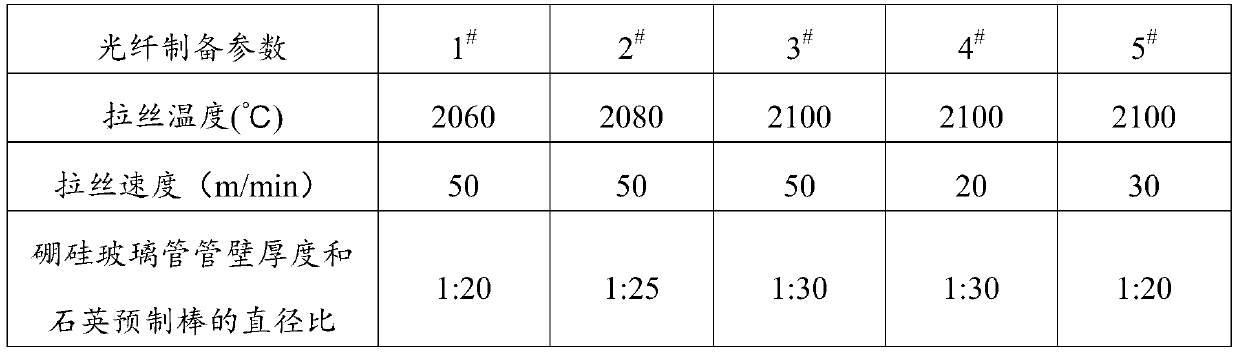

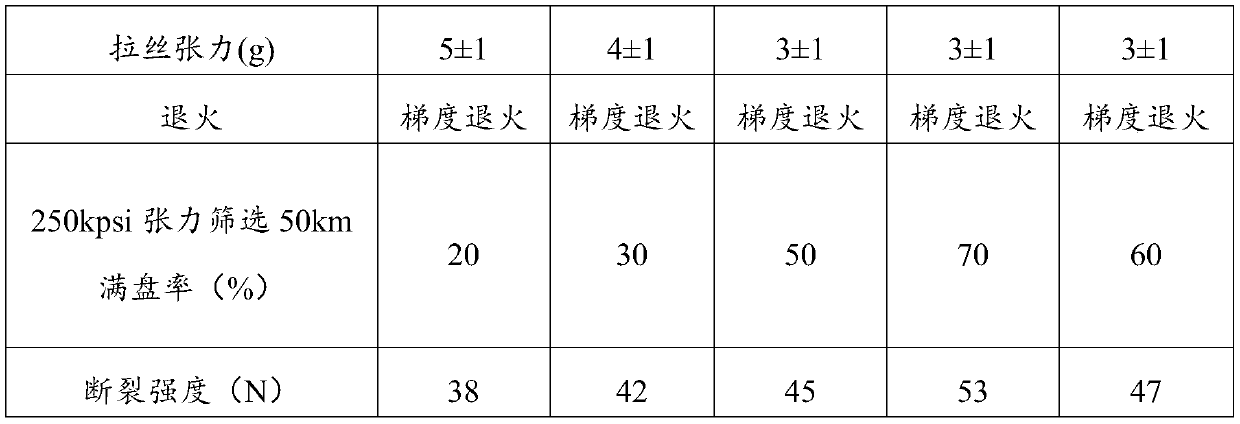

Embodiment 1

[0028] The quartz preform is pretreated before wire drawing, that is, the quartz preform is flame polished on the preform processing lathe, the flame temperature is controlled at 1600-1650°C, the rotation speed of the quartz preform is 30 rpm, and the flame moving speed is 120mm / min. After flame polishing, put the quartz preform into the annealing furnace for annealing without waiting for the quartz preform to cool down. The annealing temperature is from 1500°C to 900°C at a rate of 10°C / hour, and then cooled to room temperature. Use 3:1 HF acid and HNO for the annealed quartz preform 3 The acid mixture is used for etching, and the etching time is 15 minutes. After the etching is completed, a thin-walled borosilicate glass tube is coated on the quartz preform. The ratio of the wall thickness of the borosilicate glass tube to the diameter of the quartz preform is 1:20, and then wire drawing is carried out. Drawing parameters are as in Table 1 1 # As shown in the samples, the...

Embodiment 2

[0030] Before the wire drawing, the quartz preform is pretreated, and the pretreatment method is the same as in Example 1. After the pretreatment, a thin-walled borosilicate glass tube is placed on the quartz preform, and the thickness of the borosilicate glass tube wall and the diameter ratio of the preform are 1:25, using 2 in Table 1 # Drawing with the same parameters, the drawing temperature is 2080°C, the splicing speed is 50m / min, the drawing tension is controlled within the range of 4±1g during the drawing process, gradient annealing is carried out during the drawing process, and the annealing temperature gradually changes from the entrance to the exit temperature from 1500°C To 500°C, brushed with acrylic resin coating. After the wire drawing is completed, the mechanical properties of the optical fiber are tested, and the results are shown in Table 1. The tension is 250kpsi for screening, the screening length is 50km, and the full disk rate is 30%. The breaking streng...

Embodiment 3

[0032] Before wire drawing, the quartz preform is pretreated. The pretreatment method is the same as in Example 1. After the pretreatment, a thin-walled borosilicate glass tube is placed on the preform. The thickness of the borosilicate glass tube wall and the diameter ratio of the preform are 1. : 30, using 3 in Table 1 # The drawing temperature is 2100°C, the drawing speed is 50m / min, the drawing tension is controlled within the range of 3±1g during the drawing process, gradient annealing is carried out during the drawing process, and the annealing temperature is gradually changed from 1500°C to 1500°C from the entrance to the exit. 500°C, brushed with acrylic resin coating. After the wire drawing is completed, the mechanical properties of the optical fiber are tested, and the results are shown in Table 1. The tension is 250kpsi for screening, the screening length is 50km, and the full disk rate is 50%. The breaking strength of the optical fiber was tested, and the breaking...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com