Quartz optical fiber and preparation method and device thereof

A technology of silica optical fiber and optical fiber preform, which is applied in the field of silica optical fiber, can solve the problems of optical fiber mechanical strength reduction, transmission influence, and optical transmission impact, and achieve the effects of reducing microcracks, increasing tensile strength, and prolonging mechanical life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

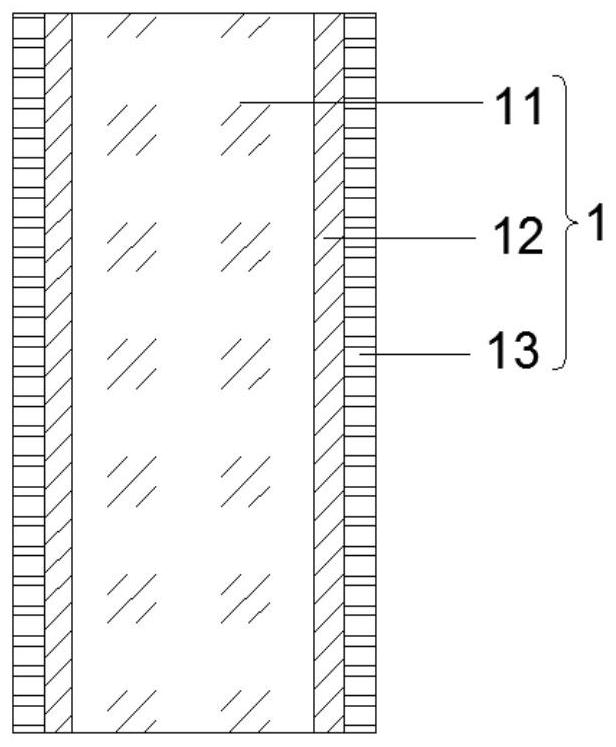

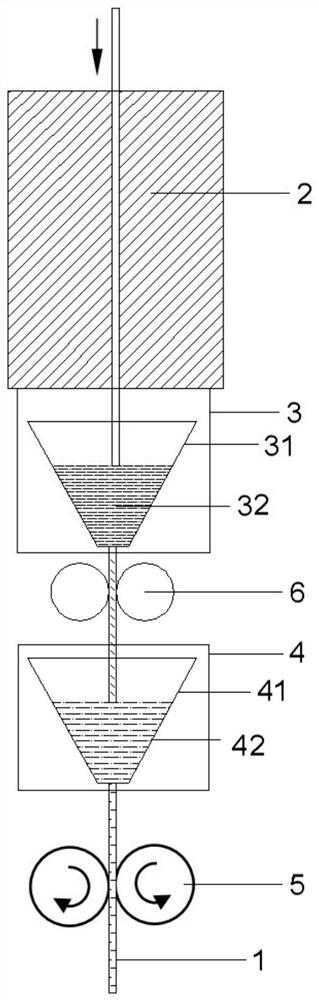

[0038] A method for preparing a silica optical fiber proposed in an embodiment of the present invention specifically includes the following steps:

[0039] Step 1, before the temperature of the drawn silica bare optical fiber drops to its glass transition temperature, coat the glass-ceramic liquid on the surface of the bare silica optical fiber to form a glass-ceramic coating, wherein the expansion coefficient of the glass-ceramic is less than 5×10 -7 / °C, preferably the expansion coefficient of the glass-ceramics is 5×10 -9 ~5×10 -7 / °C, the melting temperature is 1200°C-1400°C; the core layer and the skin layer of the bare silica optical fiber are both made of quartz glass.

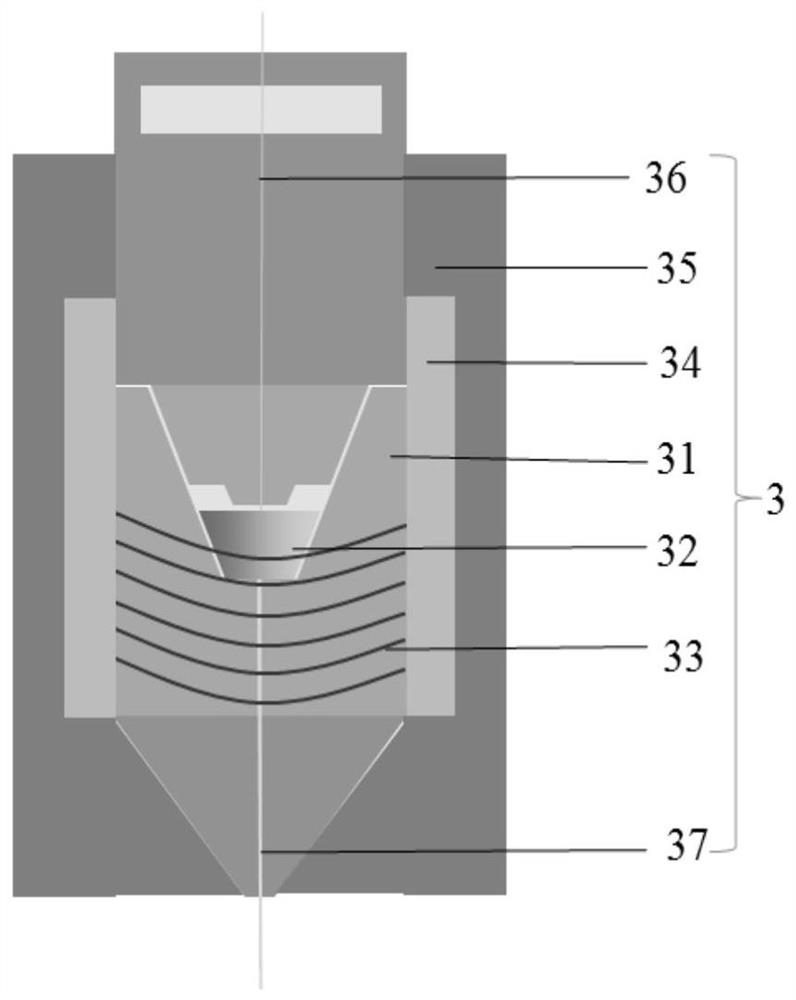

[0040] The preparation steps of the glass-ceramic liquid specifically include: heating the raw material of the glass-ceramic glass until melting, and clarifying to obtain the glass-ceramic liquid, and keeping the glass-ceramic liquid at a temperature of 1200°C to 1450°C.

[0041] The step of coating ...

Embodiment 1

[0087] (1) Weigh Li 2 O powder 329g, Al 2 o 3 Powder 216g, SiO 2 Powder 127.6g, TiO 2 Powder 20.6g, Sb 2 o 3 Powder 2.5g, ZnO powder 1.5g; Mix the weighed powder and stir evenly, then divide the powder into 6 parts, each 116g;

[0088] (2) Preheat a 500mL corundum crucible in a muffle furnace at 800°C for 2 hours, and then heat it to 1200°C. At this time, add 1 part of the powder obtained in step (1), heat it up to 1430°C in 15 minutes, keep it for 20 minutes, and then Add the second part and keep it warm for 20 minutes, and then add to the sixth part in turn; after the powder is completely melted, clarify it at 1520°C for 2 hours; preheat the platinum-coated cup to 1430°C and keep it warm. Introduce into the platinum coating cup at high temperature;

[0089] (3) Introduce the drawn high-temperature bare optical fiber from the top of the optical fiber preform melting and drawing mechanism, and adjust the axis position of the high-temperature bare optical fiber coming ou...

Embodiment 2

[0093] (1) Weigh Li 2 O powder 312g, Al 2 o 3 Powder 218g, SiO 2 Powder 130g, TiO 2 Powder 27g, Sb 2 o 3 Powder 2g, ZnO powder 3g. Mix the weighed powder and stir evenly, then divide the powder into 6 parts, each 115.3g;

[0094] (2) Preheat a 500mL corundum crucible in a muffle furnace at 800°C for 2 hours, and then heat it to 1200°C. At this time, add 1 part of the powder obtained in step (1), heat it up to 1400°C in 15 minutes, keep it for 20 minutes, and then Add the second part and keep it warm for 20 minutes, and then add to the sixth part in turn; after the powder is completely melted, clarify it at 1550°C for 2 hours; preheat the platinum crucible to 1430°C and keep it warm, and put the glass The liquid is introduced into the platinum coating cup at high temperature;

[0095] (3) Drawing is carried out by the same process as in Example 1. When the temperature of the drawn high-temperature silica bare optical fiber drops to 1650° C., pass the high-temperature si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com