Manufacturing method of high-performance concrete

A technology of high-performance concrete and its production method, which is applied in the field of concrete, can solve problems affecting the mechanical properties and working performance of concrete, the unreasonable consistency of concrete mixture, and the poor performance of concrete admixtures, etc., so as to ensure the quality of concrete and the compressive strength The effect of high specific ratio and optimized particle gradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

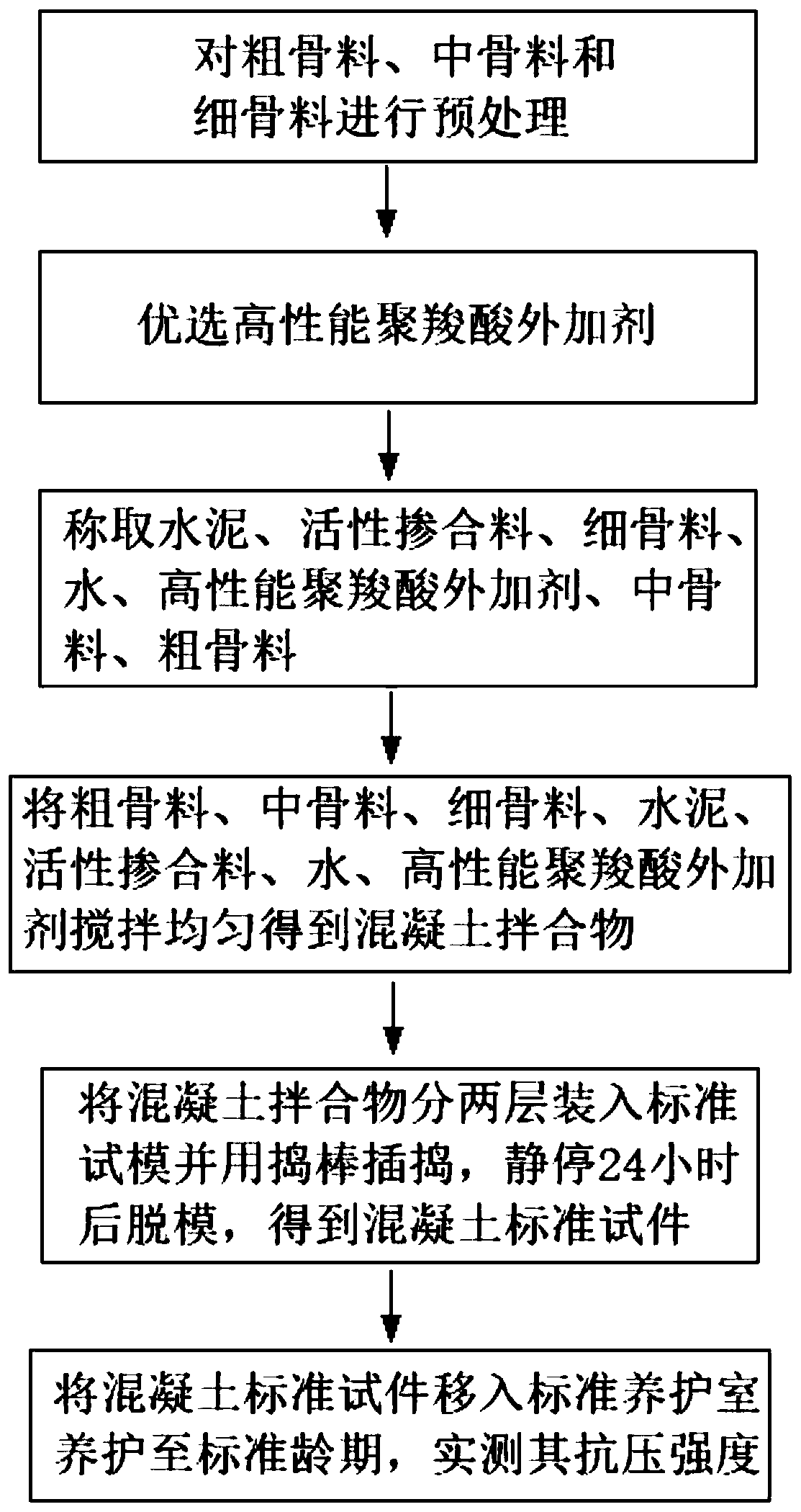

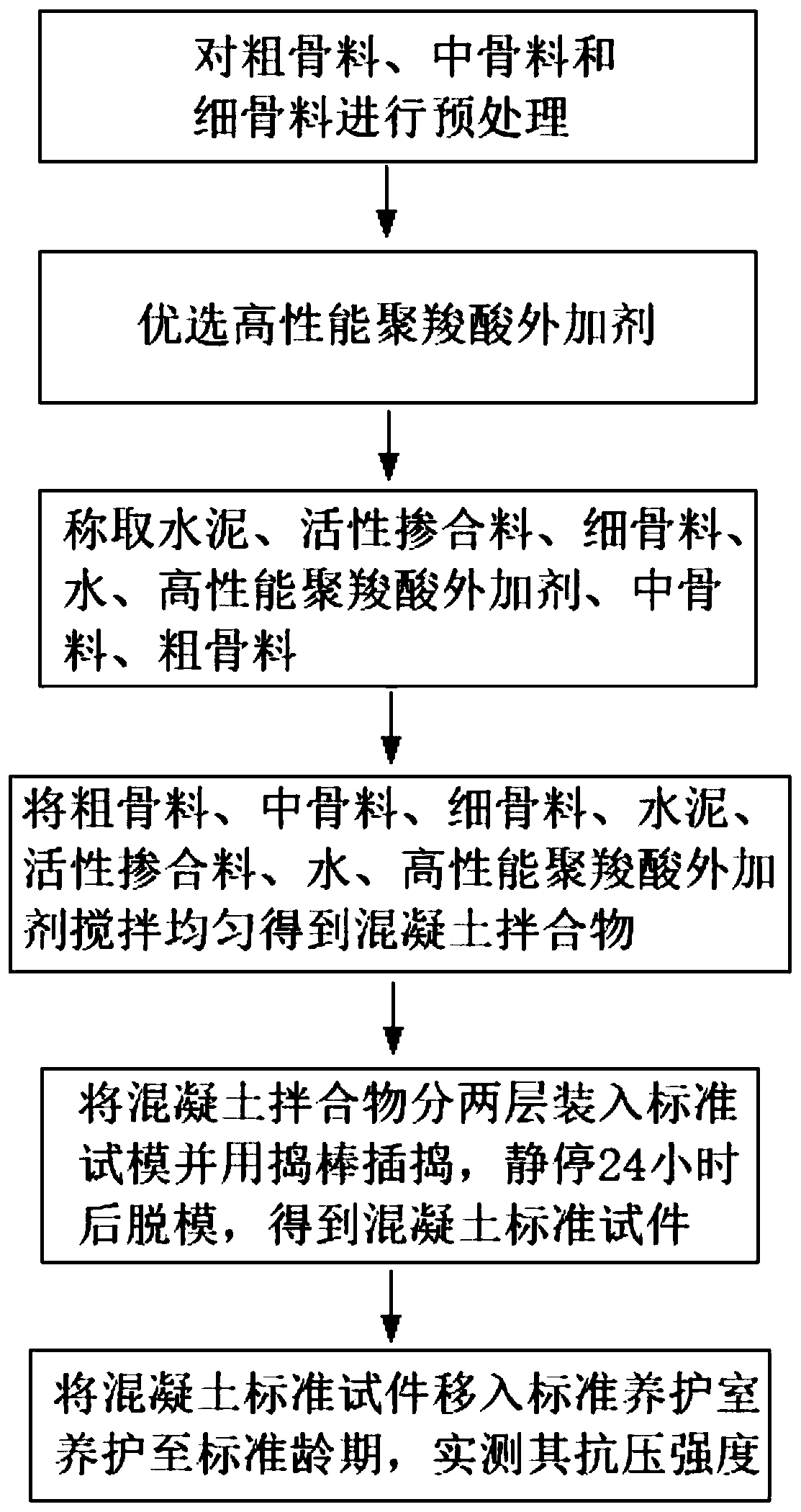

[0025] refer to figure 1 , a high-performance concrete production method, comprising the following specific steps:

[0026] S1. Screening of coarse aggregate, medium aggregate and fine aggregate; shaping treatment of coarse aggregate, medium aggregate and fine aggregate; washing of coarse aggregate, medium aggregate and fine aggregate ;

[0027] S2. Preferred high-performance polycarboxylic acid admixture;

[0028] S3. Weigh cement, active admixture, fine aggregate, water, high-performance polycarboxylic acid admixture, medium aggregate, and coarse aggregate respectively according to the formula quantity;

[0029] S4. Put coarse aggregate, medium aggregate, fine aggregate, cement, active admixture, water, and high-performance polycarboxylate admixture into a forced mixer in order to mix evenly to obtain a concrete mixture. The mixing tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com