A kind of airtight anti-fire extinguishing composite material for mine and preparation method thereof

A composite material, fire-fighting technology, used in fire-retardant coatings, conductive coatings, chloroprene homopolymer coatings, etc., can solve the problems of toxic and harmful gases, great harm to human body, and poor resistance to deformation, etc. Achieve the effects of good adhesion and elongation at break, good antistatic properties, and superior sealing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

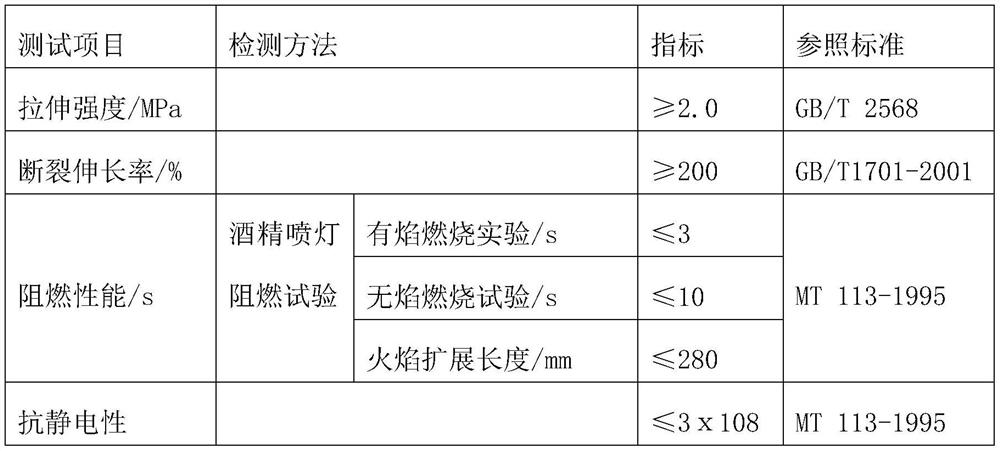

Examples

Embodiment 1

[0023] A kind of airtight anti-fire extinguishing composite material for mines described in this embodiment is composed of A, B, and C components calculated by mass content, wherein:

[0024] Component A: Portland cement 15g, aluminate cement 25g, heavy calcium carbonate 5g, kaolin 5g, quartz sand 5g, slag powder 1g, flame retardant 3g, dispersible latex powder 1g, cellulose ether 0.5 g, 1g of water reducing agent, 0.05g of polymer fiber, 0.5g of cement curing agent;

[0025] Component B: 40g of polyvinyl acetate emulsion, 20g of polyacrylate emulsion, 1g of styrene-acrylic emulsion, 5g of polychloroprene emulsion, 1g of diluent;

[0026] Component C: 30g of saturated superabsorbent resin.

[0027] The flame retardant in the A component is antimony trioxide powder flame retardant, the water reducer is polycarboxylate water reducer, the cement curing agent is calcium sulfate, and the cellulose ether is cellulose ether-450. Quartz sand is 80 mesh quartz sand, and ground calciu...

Embodiment 2

[0036] This embodiment describes a mine-used airtight fire-proof composite material, which is composed of A, B, and C components calculated by mass content, wherein:

[0037] Component A: Portland cement 35g, aluminate cement 45g, heavy calcium carbonate 10g, kaolin 10g, quartz sand 10g, slag powder 5g, flame retardant 5g, dispersible latex powder 3g, cellulose ether 1g , water reducing agent 3g, polymer fiber 0.1g, cement curing agent 1g;

[0038] Component B: 70g polyvinyl acetate emulsion, 40g polyacrylate emulsion, 5g styrene-acrylic emulsion, 10g polychloroprene emulsion, 5g diluent;

[0039] Component C: 50g of saturated superabsorbent resin.

[0040] The flame retardant in the A component is antimony trioxide powder flame retardant, the water reducer is polycarboxylate water reducer, the cement curing agent is anhydrous sodium sulfate, and the cellulose ether is cellulose ether- 450, quartz sand is 80 mesh quartz sand, and heavy calcium carbonate is 80 mesh heavy calc...

Embodiment 3

[0049] A kind of airtight anti-fire extinguishing composite material for mines described in this embodiment is composed of A, B, and C components calculated by mass content, wherein:

[0050] Component A: Portland cement 25g, aluminate cement 35g, heavy calcium carbonate 8g, kaolin 8g, quartz sand 8g, slag powder 3g, flame retardant 4g, dispersible latex powder 2g, cellulose ether 0.7 g, 2g of water reducing agent, 0.08g of polymer fiber, 0.6g of cement curing agent;

[0051] Component B: 55g polyvinyl acetate emulsion, 30g polyacrylate emulsion, 3g styrene-acrylic emulsion, 8g polychloroprene emulsion, 3g diluent;

[0052] Component C: 40g of saturated superabsorbent resin.

[0053] The flame retardant in the A component is antimony trioxide powder flame retardant, the water reducer is polycarboxylate water reducer, the cement curing agent is calcium sulfate or anhydrous sodium sulfate, and the cellulose ether is fiber Plain ether-450, quartz sand is 80 mesh quartz sand, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap