Biomass granular fuel preparation device

A technology for the preparation of biomass particles and fuels, which is applied in the direction of biofuels, waste fuels, fuels, etc., can solve the problems of complicated operations, uneven pressure on particles, and restrictions on the application and development of biomass fuels, so as to prevent spillage and prevent The effect of jamming and reducing the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

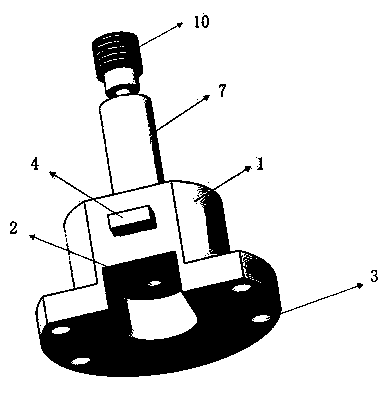

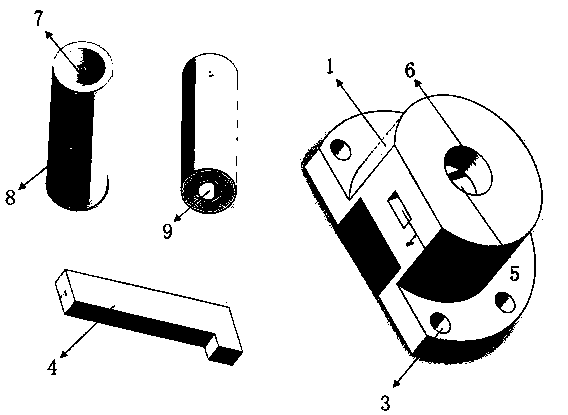

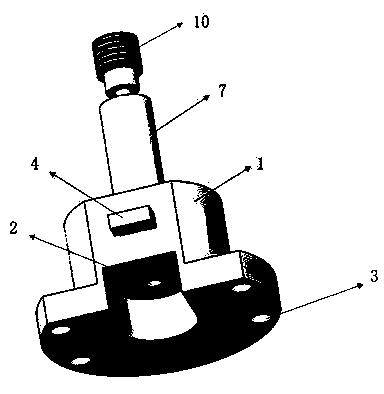

[0019] A kind of biomass particle fuel preparation device, as attached figure 1 And attached figure 2 As shown, it consists of base (1), discharge port (2), fixing hole (3), pull-out stripping plate (4), stripping plate track (5), barrel holder (6), barrel ( 7), barrel inlet (8), barrel outlet (9) and punch (10). The punch (10) is inserted into the barrel (7) from the feed port (8) of the barrel; the barrel (7) is placed in the center of the upper layer of the base (1) and fixed in the barrel holder (6); The lower part of the card seat (6) faces the stripping plate track (5) and the barrel outlet (9) in turn; the stripping plate track (5) runs through the upper layer of the base (1) in the radial direction, and the pull-out stripping plate (4) inserted therebetween; four fixing holes (3) are provided on the lower layer of the base (1) for device fixing.

[0020] Among them, the diameter of the upper layer of the base (1) is 105 mm, and the height is 50 mm; the diameter of ...

Embodiment 2

[0022] A method for preparing corn stalk pellet fuel by using the biomass pellet fuel preparation device:

[0023] First, corn stalks were selected as raw materials, and the corn stalks were crushed to make the particle size less than 80 meshes, and then placed in an oven at 105 °C for 24 hours. Because moisture is a natural binder, it can improve the mechanical strength of the granular fuel, so before starting to press the pellets, add 10% moisture to the crushed and dried raw materials and mix them evenly. Then, weigh 1g of the raw material after the above treatment, slide it into the barrel (7) along the inclined surface of the barrel feed port (8) of the biomass particle fuel preparation device, and then prepare the biomass particle fuel The device is fixed on the universal testing machine, and the pressure is gradually increased. After the pressure reaches 5MPa, the pressure is stopped, and the state is maintained for 2 minutes. Then, the pressure is reduced and the pull-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com