Synthetic leather for children products and preparation method thereof

A technology of synthetic leather and supplies, which is applied in the field of synthetic leather, can solve the problems of high price, very high environmental protection requirements, and high cost of children's products, and achieve the effect of reducing production costs and enriching products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The synthetic leather for children's products provided in this embodiment comprises a base cloth layer, a PU bottom layer and a PU surface layer arranged in sequence, and a TPU bonding layer is passed between the base cloth layer and the PU bottom layer.

[0031] The raw material formula of the TPU adhesive layer is 100 parts of TPU particles and 0.2 parts of leveling agent. The TPU particles are WHT-8170, purchased from Wanhua Company; the leveling agent is BYK-9565, purchased from Stahl.

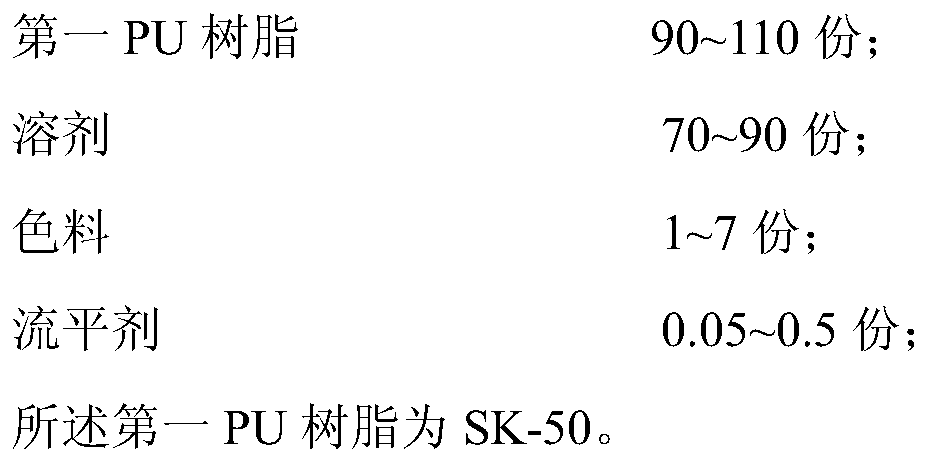

[0032] The raw material formula of the PU surface layer is 100 parts of SK-50PU resin, 80 parts of ethyl ester, 4 parts of 234s colorant and 0.2 part of BYK-9565 leveling agent. Among them, SK-50 comes from Huafeng, and 234s colorant comes from Huapu.

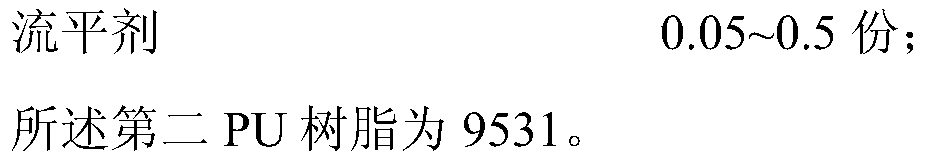

[0033] The raw material formula of the PU bottom layer is 100 parts of 9531PU resin, 80 parts of ethyl ester, 4 parts of 234s colorant and 0.2 parts of BYK-9565 leveling agent. Among them, 9531PU resin comes from Hexin.

[0034] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com