Five-milling slotting construction method for underground diaphragm wall unit slot like Chinese character of 'bian'

A technology of trough-forming construction and unit trough, which is applied in artificial islands, sheet pile walls, water conservancy projects, etc., can solve the problems of poor integrity and anti-seepage of wall connection parts, long construction period, etc., and shorten the trough formation Construction time, enhanced integrity and anti-seepage, good effect of verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

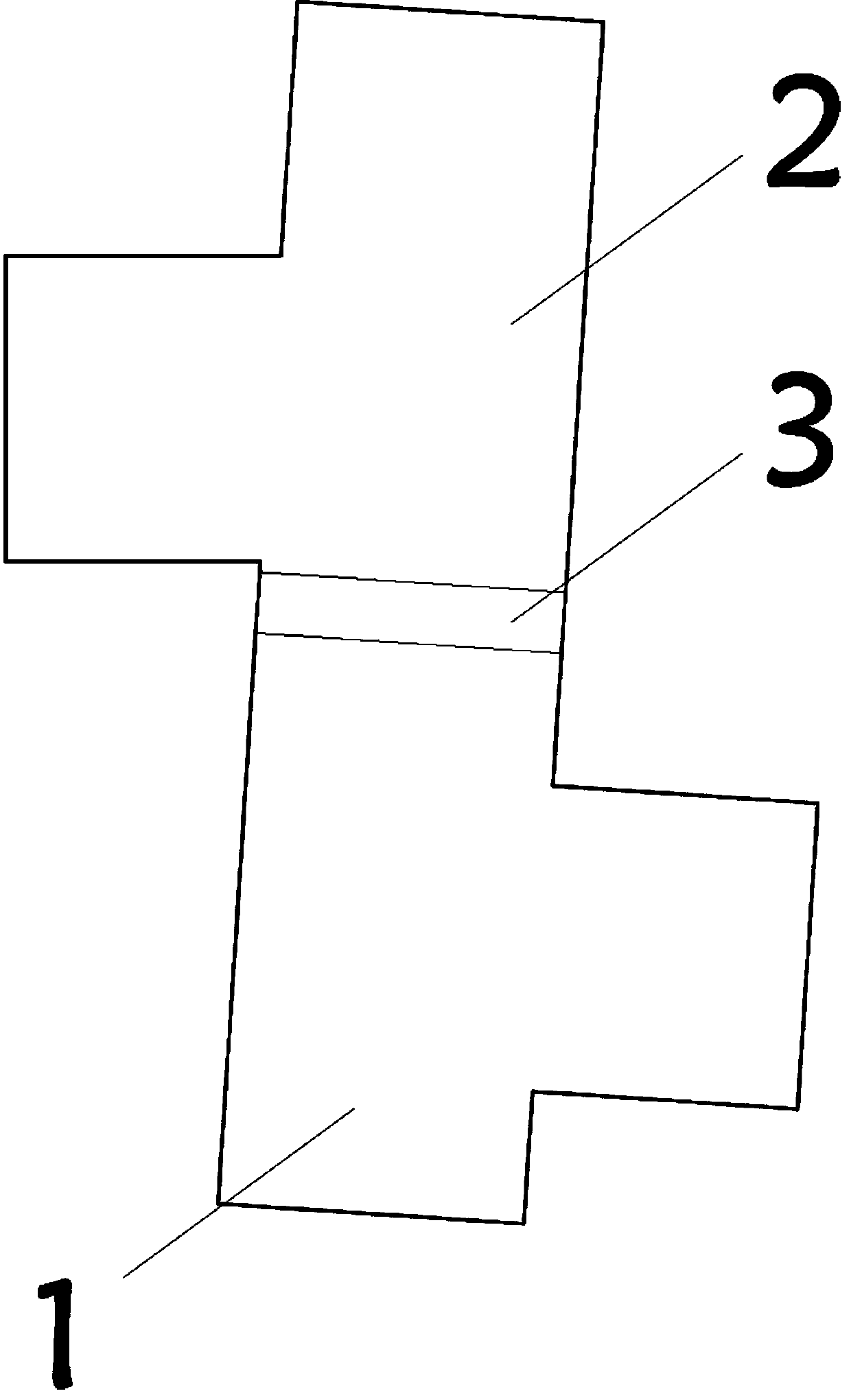

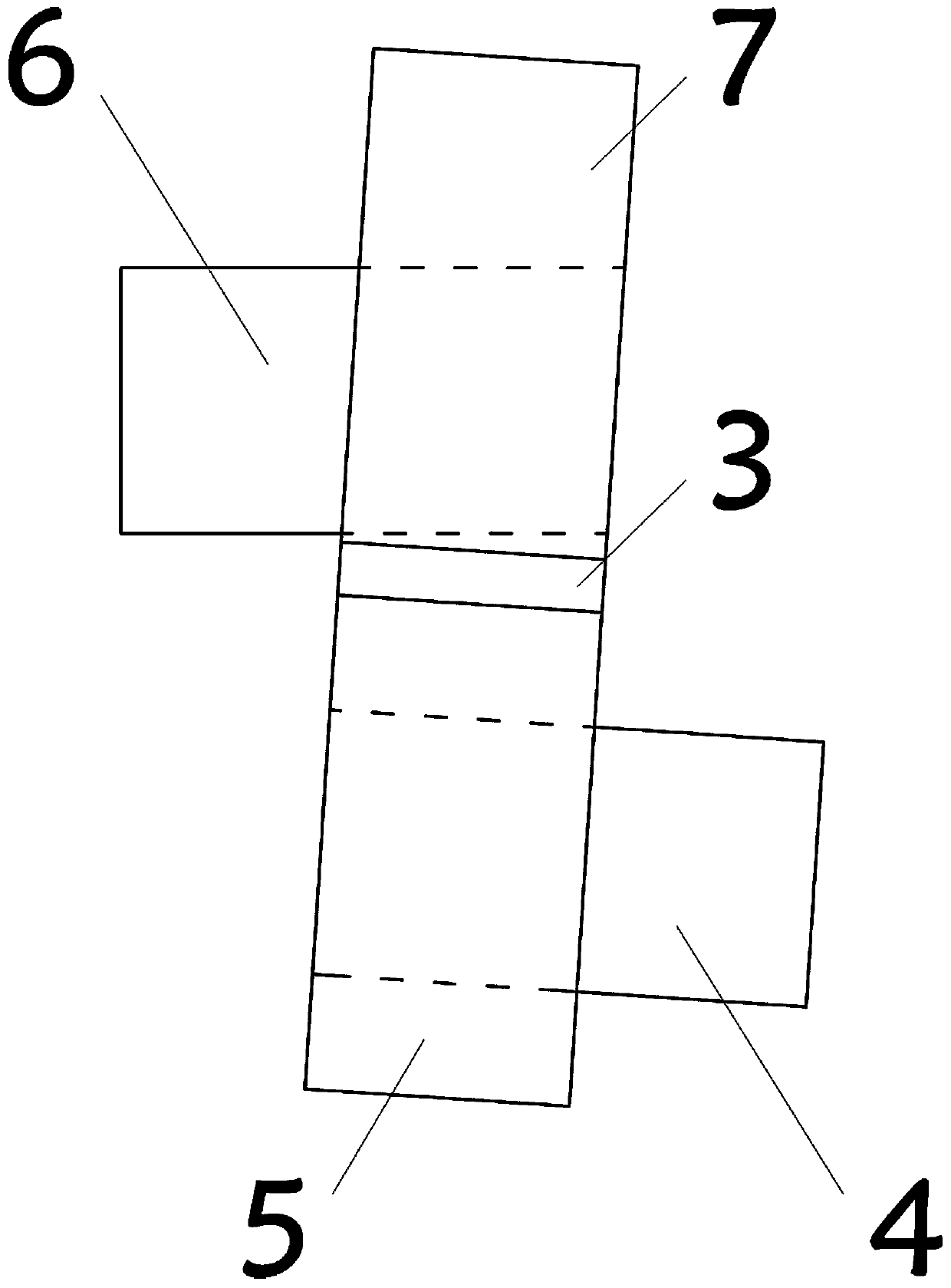

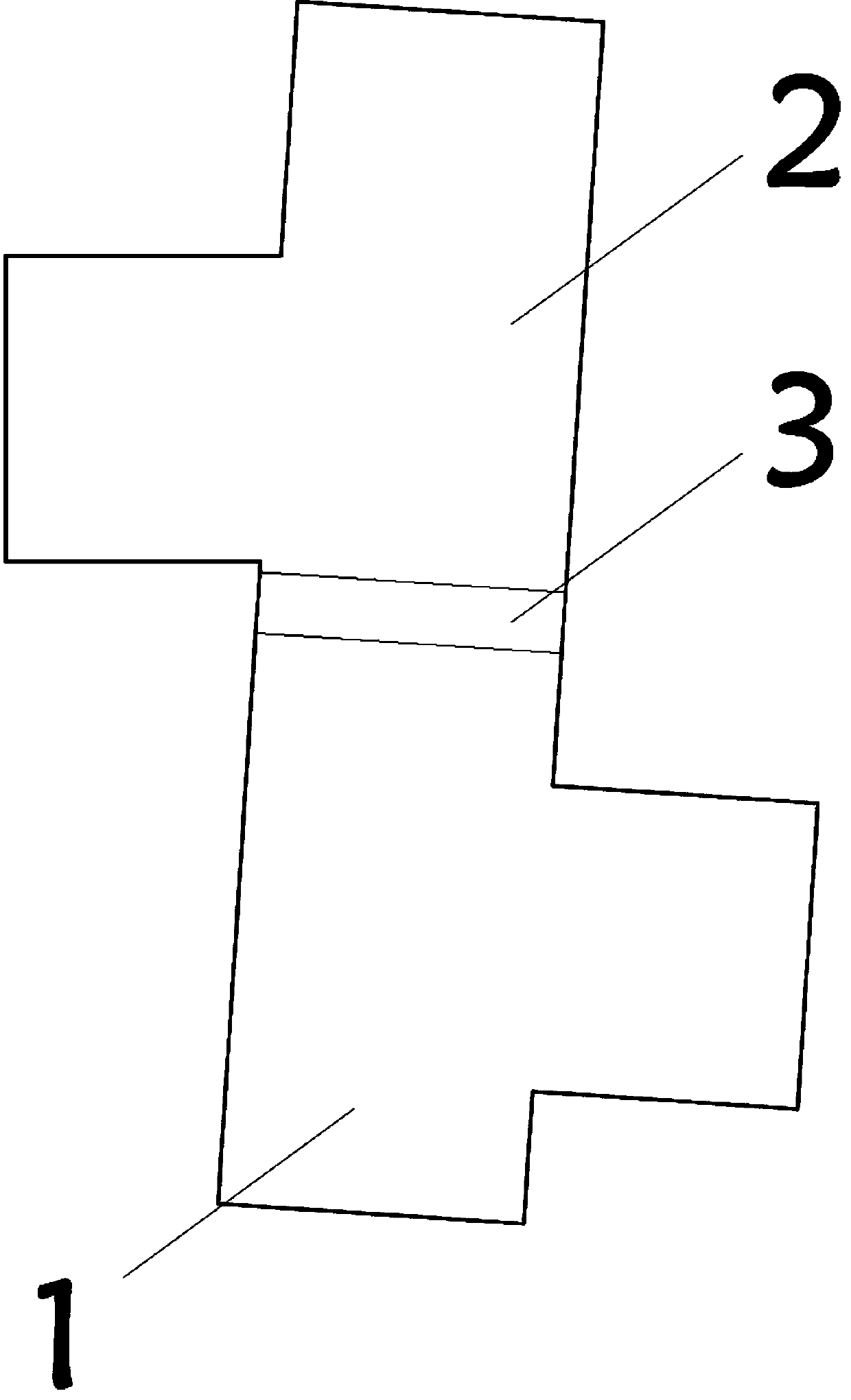

[0027] Such as Figure 1-2 Among them, a five-milling construction method for the "Bian"-shaped unit groove section of the ground connection wall is divided into the first "T"-shaped section 1, the second "T"-shaped section 2 and the connecting wall "Bian"-shaped unit groove. Seam section 3 is constructed in three sections.

[0028] In the preferred solution, the first "T"-shaped section 1 and the second "T"-shaped section 2 are respectively set as two sections of main holes for grooving construction, and the joint section 3 is set as auxiliary holes for final grooving .

Embodiment 2

[0030] The five-milling construction method of the "Bian"-shaped unit groove section specifically includes the following steps:

[0031] 1) Preparatory work for construction;

[0032] 2) According to the milling construction sequence, the "Bian"-shaped unit groove section of the ground connection wall is divided into four main holes and one auxiliary hole;

[0033] 3) After the wall is solidified with mud, use the "pure milling method" of the double-wheel milling machine, and carry out the construction according to the principle of milling the main hole first and milling the auxiliary hole second.

Embodiment 3

[0035] On the basis of Example 2, the step 1) specifically includes guide wall construction, hydropower system formation, mud preparation, and double-wheel milling machine in place.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com