Local heat preservation freezing method during coal mine deep vertical shaft freezing method construction

A freezing method and freezing method technology are applied in the field of local thermal insulation and freezing during the construction of deep shaft freezing method in coal mines, which can solve the problems of difficult wellbore excavation construction, increased freezing costs, collision damage, etc., and achieve low cost, controllable quality, and reduced The effect of construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0023] A kind of coal mine deep shaft freezing method construction of the present invention local thermal insulation freezing method, comprises the following steps:

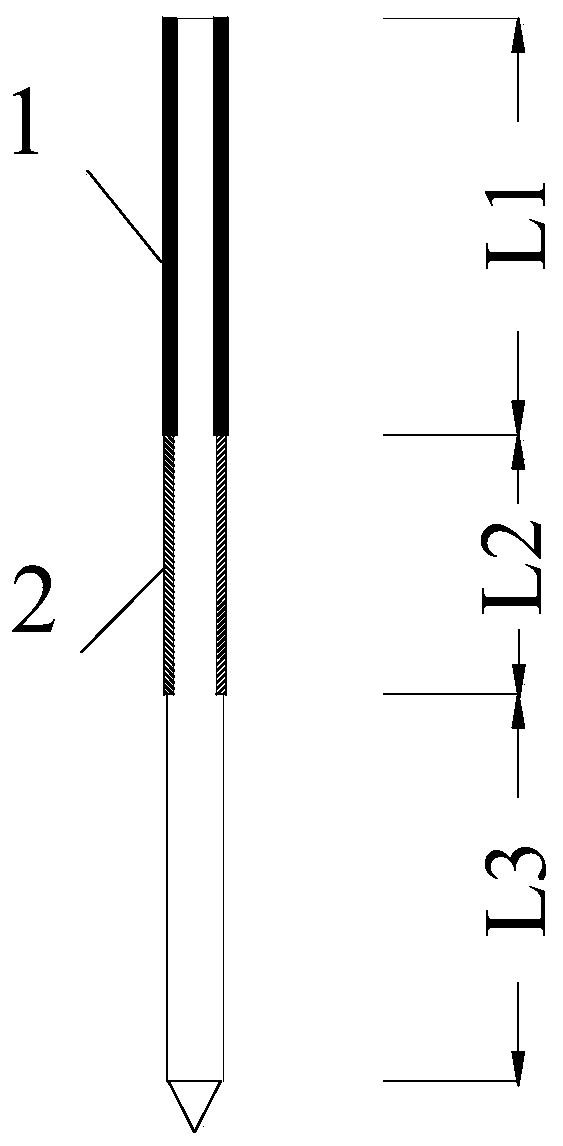

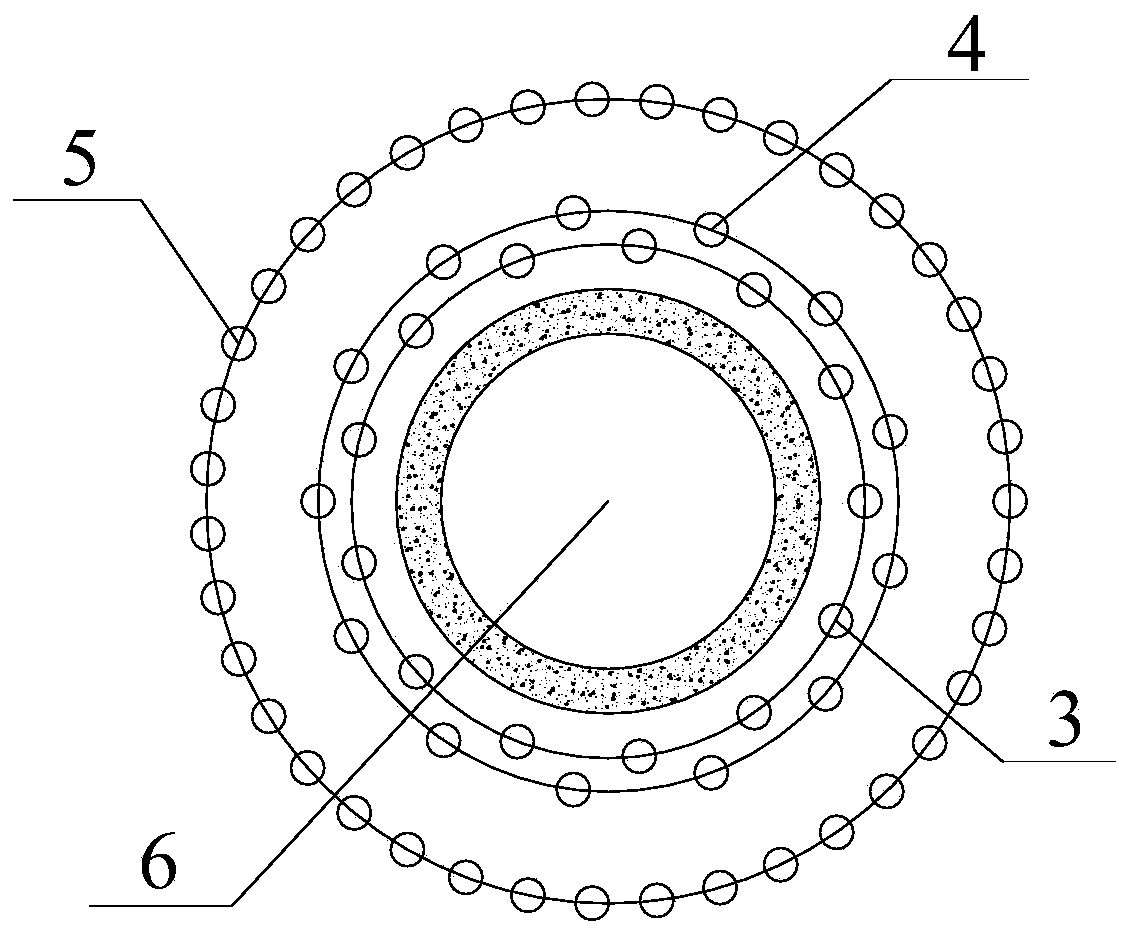

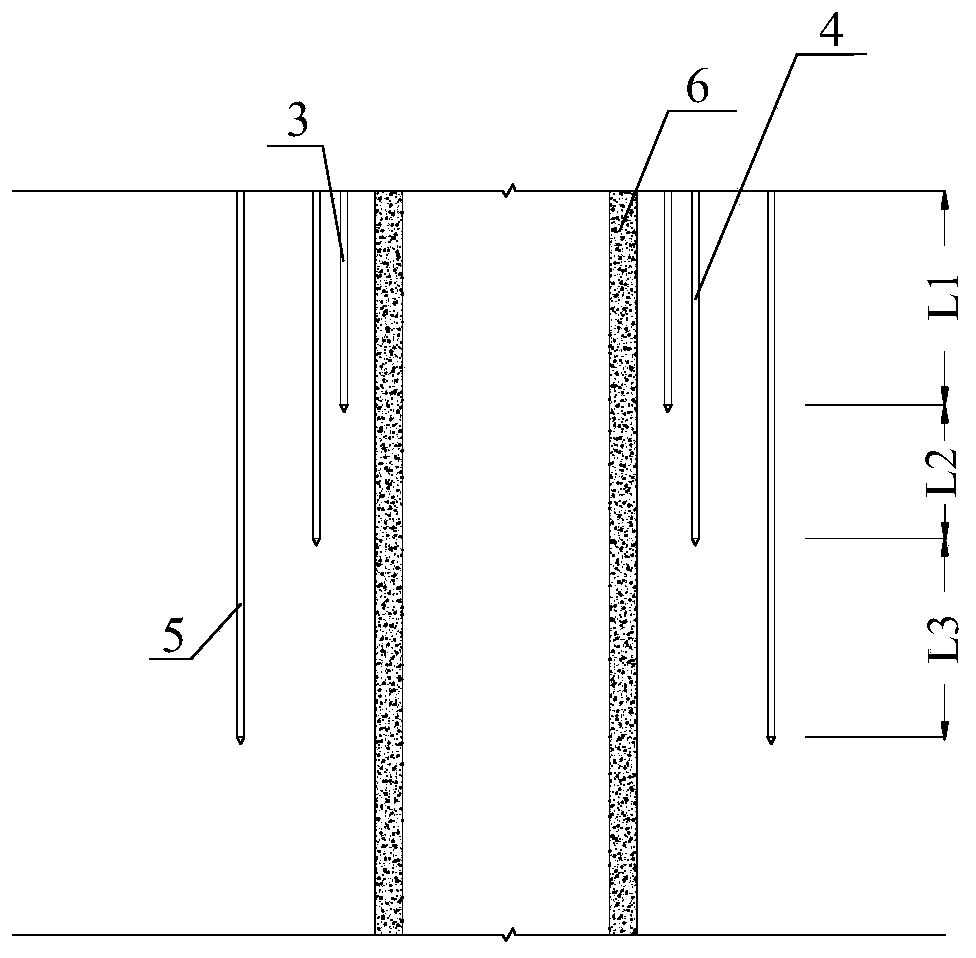

[0024] (a) Review the prepared freezing plan, record the depth of the inner ring freezing hole, the middle ring freezing hole depth, and the outer ring freezing hole depth, and define the inner ring freezing hole depth as L1, and the middle ring freezing hole depth as L2.

[0025] (b) The frozen pipes transported into the project site shall be classified and managed according to the frozen pipes of the inner ring hole, the frozen pipes of the middle ring hole and the frozen pipes of the outer ring hole, and the frozen pipes to be L1 and L2 shall be selected from the frozen pipes of the outer ring hole Tube, clearly marked.

[0026] (c) Clean the surface of the frozen tubes that have been plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com